Product Description

High Precision HGR15 HGR20 HGR25 CNC Linear Xihu (West Lake) Dis. Rail Linear Xihu (West Lake) Dis. Block Carriage for CNC Router

Product Description

Specification:

|

Product Name |

Linear CZPT |

|

Material |

Bearing steel, Gcr15 |

|

Precision |

C, H, P |

|

Width |

15mm-45mm |

|

Length |

100mm-4000mm |

|

Advantage |

High precision, high speed, long life, high reliability, low noise |

|

Packing |

Plastic bag + wooden box or according to customers’ demands |

Packaging & Shipping

Packaging Details:

1)Sample order packing by paper carton for saving freight charge;

2)bulk order sent by sea will be packed by film and wooden carton.

3) as customer’s requirements.

Company Profile

Company Information:

ZheJiang Sair Mechanical Xihu (West Lake) Dis. Co., Ltd is located at Xihu (West Lake) Dis. industrial zone Xihu (West Lake) Dis. County which is the beautiful Xihu (West Lake) Dis.

Water City and the famous painting and calligraphy village.The south is national road 308, the west is the national highway 105,

the north is HangZhou-HangZhou highway, so the position is very superior. It is 1 of the biggest linear manufacturers in China.

Certifications

FAQ

1. Q: How about the quality of your product?

A: 100% inspection during production.

Our products are certified to ISO9001-2008 international quality standards.

2. Q: What’s the delivery time?

A: For custom order, within 2000 meters,

Production time is 15days after confirmed every details.

3. Q: What’s your packing?

A: Our Normal packing is bulking in PE bag, and then into plywood Cartons.

We also can pack products according to your requirement.

4. Q: What about the warranty?

A: We are very confident in our products,

and we pack them very well to make sure the goods in well protection.

5.Q: Could you send me your catalogue and price list?

A: As we have more than hundreds of products,

it is really too hard to send all of catalogue and price list for you.

Please inform us the style you interested, we can offer the pricelist for your reference.

6.Q:There are a lot of companies which export bearings, why do you choose us?

A: As we are a genuine linear CZPT supplier since 2011.and we are really factory, you need not pay the profit for middlemen.

so we can offer you the lowest and competitive price .

Thanks for your valuable time !

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | CNC Machine Parts |

|---|---|

| Material: | Gcr15 Bearing Steel |

| Structure: | Linear Guide Rail |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do I choose the right block bearing for my machinery?

Choosing the right block bearing for your machinery is crucial to ensure optimal performance, reliability, and longevity. Here’s a detailed explanation of the factors to consider when selecting a block bearing:

- Load Requirements: Determine the load requirements of your machinery, including the magnitude and direction of the loads that will be applied to the bearing. Consider factors such as static loads, dynamic loads, and shock loads. This information will help you choose a block bearing with the appropriate load-carrying capacity and load rating.

- Speed and Operating Conditions: Consider the speed at which your machinery will operate and the corresponding operating conditions. High-speed applications may require block bearings with specific design features, such as lower friction, improved heat dissipation, and higher precision. Additionally, assess the operating environment for factors like temperature, humidity, dust, and chemical exposure, as these can impact the choice of bearing materials and seals.

- Bearing Type and Configuration: Choose the appropriate bearing type and configuration based on your machinery’s requirements. Common types of block bearings include ball bearings, roller bearings, and spherical bearings. Consider factors such as the type of motion, misalignment compensation, and ease of installation when selecting the bearing type.

- Bearing Size and Shaft Diameter: Determine the required bearing size and shaft diameter for your machinery. The bearing should be properly sized to handle the loads and fit securely on the shaft. Refer to manufacturer guidelines or consult engineering resources to determine the appropriate bearing size and shaft diameter for your specific application.

- Sealing and Lubrication: Consider the sealing and lubrication requirements of your machinery. Sealing arrangements help protect the bearing from contaminants and retain lubrication. Choose the appropriate sealing options based on the operating environment and the desired level of protection. Additionally, select the right lubricant and lubrication method based on factors such as operating speed, temperature, and load conditions.

- Industry Standards and Regulations: Ensure that the selected block bearing complies with relevant industry standards and regulations. Compliance with standards such as ISO, ANSI, or ABMA ensures that the bearing meets quality and performance requirements.

- Consult Manufacturer or Supplier: If you are unsure about the appropriate block bearing for your machinery, consult the manufacturer or a reputable supplier. They can provide expert guidance, technical support, and recommend suitable products based on their experience and knowledge.

By considering these factors and seeking expert advice when needed, you can choose the right block bearing that matches the requirements of your machinery, ensuring reliable and efficient operation.

Are block bearings available in stainless steel?

Yes, block bearings are available in stainless steel variants to meet specific application requirements. Stainless steel block bearings are designed to provide corrosion resistance and durability in environments where standard bearings may be susceptible to corrosion or chemical attack. Here are some key points about stainless steel block bearings:

1. Stainless Steel Material: Stainless steel block bearings are typically made from high-quality stainless steel materials, such as AISI 304 or AISI 316. These materials offer excellent corrosion resistance, mechanical strength, and dimensional stability.

2. Corrosion Resistance: Stainless steel block bearings are specifically designed to withstand corrosive environments, including exposure to moisture, chemicals, or harsh substances. They are commonly used in industries such as food processing, pharmaceuticals, chemical processing, marine applications, and outdoor equipment.

3. Lubrication: Stainless steel block bearings may require special lubrication considerations to ensure optimal performance and longevity. Some lubricants used with stainless steel bearings are specifically formulated to be compatible with stainless steel and provide enhanced corrosion protection.

4. Bearing Types: Stainless steel block bearings are available in various bearing types, such as deep groove ball bearings, spherical roller bearings, or tapered roller bearings. The specific bearing type depends on the application requirements, load capacity, and operating conditions.

5. Design Options: Stainless steel block bearings are available in different designs and configurations, including standard duty, heavy-duty, self-aligning, or flange block designs. The selection of the design depends on the specific application needs and load requirements.

6. Temperature Limitations: It’s important to consider the temperature limitations of stainless steel block bearings. While stainless steel offers good resistance to corrosion, the operating temperature range may be lower compared to other bearing materials. It is essential to consult the manufacturer’s specifications to ensure that the stainless steel block bearing is suitable for the intended temperature conditions.

7. Application Considerations: When selecting stainless steel block bearings, it’s crucial to consider the specific application requirements, load conditions, environmental factors, and operating conditions. Stainless steel block bearings may have different load capacities or temperature limits compared to their non-stainless steel counterparts.

Stainless steel block bearings provide a reliable solution for applications that demand corrosion resistance and durability. They offer protection against rust, pitting, and other forms of corrosion, making them suitable for use in challenging environments. However, it’s important to note that stainless steel block bearings may have different cost considerations compared to standard bearings due to the higher material and manufacturing costs associated with stainless steel.

Consulting with bearing manufacturers or suppliers can help in selecting the appropriate stainless steel block bearing that meets the specific requirements of the application and ensures reliable performance in corrosive or demanding environments.

What are the common applications of block bearings?

Block bearings, also known as pillow block bearings, are widely used in various industrial applications where there is a need to support and guide rotating or oscillating shafts. These bearings offer stability, load-carrying capacity, and ease of installation. Here’s a detailed explanation of the common applications of block bearings:

- Conveyor Systems: Block bearings are extensively used in conveyor systems found in industries such as manufacturing, mining, and logistics. They provide support and smooth motion for the conveyor belts, allowing efficient material handling and transportation.

- Fans and Blowers: Block bearings are commonly employed in industrial fans, blowers, and HVAC systems. They help support the rotating shafts of the fan blades, ensuring smooth operation and minimizing vibration.

- Pumps and Compressors: Block bearings find applications in pumps and compressors, where they support the rotating shafts and help maintain the fluid or gas flow. These bearings are essential for efficient operation and reliability in various industries, including oil and gas, water treatment, and HVAC.

- Agricultural Machinery: Block bearings are used in agricultural equipment such as harvesters, tractors, and irrigation systems. They provide support for shafts and rotating components, enabling efficient operation in demanding agricultural environments.

- Food Processing Equipment: The food processing industry often utilizes block bearings in equipment like mixers, conveyors, and packaging machinery. The bearings used in these applications are typically made of food-grade materials and designed to withstand frequent cleaning and sanitization.

- Material Handling Equipment: Block bearings are employed in a wide range of material handling equipment, including forklifts, cranes, and hoists. These bearings support the shafts and mechanisms involved in lifting, moving, and positioning heavy loads.

- Mining and Construction Machinery: Block bearings are used in heavy-duty equipment found in the mining and construction industries. They provide support and smooth rotation for components like conveyor systems, crushers, and excavators, enabling efficient operation in harsh environments.

- Printing and Packaging Machinery: Block bearings are utilized in printing presses, packaging machines, and paper processing equipment. They help support the rotating shafts and rollers, ensuring precise motion and reliable operation during printing, packaging, and paper handling processes.

- Textile Machinery: Block bearings are commonly employed in textile machinery, including spinning machines, weaving looms, and dyeing equipment. They support the rotating shafts and spindles, allowing smooth and precise movement during textile production processes.

- Automotive and Transportation: Block bearings are used in various automotive applications, such as wheel hubs, suspension systems, and transmission components. They provide support and enable smooth rotation in the automotive industry, ensuring reliable performance and comfort.

These are just a few examples of the common applications of block bearings. Due to their versatility, durability, and ability to handle substantial loads, block bearings are employed in numerous industries and equipment types where rotational motion support is required.

editor by CX 2024-05-10

China OEM Durable 1209K 22209K SNG509 Split Plummer Block Housing/Ball/Roller Bearings bearing block

Product Description

>> TANN Split Plummer Block Housings

Split the Plummer block housings are generally used for self-aligning ball bearings, barrel roller bearings, and spherical roller bearings.

Plummer blocks are bearing housings supplied without any bearings. They are usually meant for higher load ratings and corrosive industrial environments. The terms pillow block and Plummer block are used interchangeably in certain parts of the world. The disruptive strength of Plummer block varies depending on its type, nature, and direction of a load working on it, as well as the flatness of the surface to which it is installed

| FACTORY WARRANTED | -Granville can offer an array of tools for efficient to offer maintenance. -We also offer reliable systems and services to help with maintenance. -Personnel maximize operating performance and detect equipment. -Dealing with problems before they become critical. |

>> SNG500 Series

| Bearing No. | Shaft Dia d | Dimension( mm) | Housing wt (kg) | Housing No. | Locating Ring | Housing No. | |||||||||||||||||||

| d (mm) | H h12 | a | e | b | u | V | C | W | L | d1 H12 | d2 H12 | n | J | F | g H12 | Da H8 | S | Number | OTY | ||||||

| (2) | (4) | ||||||||||||||||||||||||

| SNG507-606 | 30 | 50 | 185 | 150 | 52 | 13 | 20 | 22 | 92 | 82 | 46.5 | 54.5 | 7.5 | 5 | 34 | 72 | MIO | 2.4 | 1207K 22207K | H207 H307 | SR72x&5 SA72x5.5 | 2 2 |

SNG507-606 | ||

| SNG508-607 | 35 | 60 | 205 | 170 | 60 | 15 | 20 | 25 | 106 | 85 | 51.5 | 59.5 | 7.5 | 5 | 39 | 80 | M12 | 3.2 | 1208K 22208K | H208 H308 | SR80E05 SR80x8 | 2 2 |

SNG508-607 | ||

| SNG509 | 40 | 60 | 205 | 170 | 60 | 15 | 20 | 25 | 109 | 85 | 56.5 | 64.5 | 8.5 | 5 | 30 | 85 | M12 | 3.5 | 1209K 22209K | H209 H309 | SR85x5.5 SR85x7 | 2 1 |

SNG509 | ||

| SNG510-608 | 45 | 60 | 205 | 170 | 60 | 15 | 20 | 25 | 112 | 90 | 62 | 70.5 | 8.5 | 5 | 41 | 90 | M12 | 3^5 | 1210K 22210K | H210 H310 | SR90x 10.5 SR90x9 | 2 2 |

SNG510-608 | ||

| SNG511-609 | 50 | 70 | 255 | 210 | 70 | 18 | 23 | 28 | 127 | 95 | 67 | 75.5 | 35 | 8.5 | 5 | 44 | 100 | M16 | M12 | 5.2 | 1211K 22211K | H211 H311 | SR100x11.5 SR100x95 | 2 2 |

SNG511-609 |

| SNG512-610 | 55 | 70 | 255 | 210 | 70 | 18 | 23 | 30 | 133 | 105 | 72 | 80.5 | 35 | 8.5 | 5 | 48 | 110 | M16 | M12 | 6.7 | 1212K 22212K | H212 H312 | SR110x13 SR110x10 | 2 2 |

SNG512-610 |

| SNG513-611 | 60 | 80 | 275 | 230 | 80 | 18 | 24 | 30 | 148 | 110 | 77 | 85.5 | 35 | 8.5 | 5 | 51 | 120 | M16 | M12 | 7.9 | 1213K 22213K | H213 H313 | SR120x14 SRl20x10 | 2 2 |

SNG513-611 |

| SNG515-612 | 65 | 80 | 280 | 230 | 80 | 18 | 26 | 30 | 154 | 115 | 87 | 95.5 | 40 | 8.5 | 5 | 56 | 130 | M16 | M12 | 7.7 | 1215K 22215K | H215 H315 | SR130x15.5 SR130x12.5 | 2 2 |

SNG515-612 |

| SNG516-613 | 70 | 95 | 315 | 260 | 90 | 22 | 29 | 32 | 175 | 120 | 92.5 | 101 | 40 | 10.5 | 5 | 58 | 140 | M20 | M12 | 11.0 | 1216K 22216K | H217 H317 | SR140x16 SR140x12.5 | 2 2 |

SNG516-613 |

| SNG517 | 75 | 95 | 320 | 260 | 90 | 22 | 30 | 32 | 181 | 125 | 97.5 | 106 | 50 | 10.5 | 5 | 61 | 150 | M20 | M12 | 127 | 1217K 22217K | H217 H317 | SR150x16.5 SR150x12.5 | 2 2 |

SNG517 |

| SNG51&-615 | 80 | 100 | 345 | 290 | 100 | 22 | 27 | 35 | 192 | 140 | 102.5 | 111 | 50 | 10.5 | 5 | 65 | 160 | M20 | M16 | 148 | 1218K 22218K 23218K | H218 H318 H2318 | SR160x17.5 SR160x12.5 SR160x12.5 | 2 2 1 |

SNG518-615 |

| SNG519-616 | 85 | 112 | 345 | 290 | 100 | 22 | 27 | 35 | 209 | 145 | 131 | 141 | 50 | 11.5 | 6 | 68 | 170 | M20 | M16 | 15.5 | 1219K 22219K | H219 H319 | SR170x18 SR170x12.5 | 2 2 |

SNG519-616 |

| SNG52O-617 | 90 | 112 | 380 | 320 | 110 | 26 | 32 | 40 | 215 | 160 | 137.5 | 147.5 | 60 | 11.5 | 6 | 70 | 180 | M24 | M16 | 18.4 | 1220K 22220K 23220K | H220 H320 H2320 | SR180x17.5 SR180x12.5 SR180x12.5 | 2 2 1 |

SNG520-617 |

| SNG522-619 | 100 | 125 | 410 | 350 | 120 | 26 | 32 | 45 | 239 | 175 | 147.5 | 157.5 | 70 | 11.5 | 6 | 80 | 200 | M24 | M16 | 24.8 | 1222K 22222K 23222K | H222 H322 H2322 | SR200 x 21 SR200x13.5 SR200x10.2 | 2 2 1 |

SNG522-619 |

| SNG524-620 | 110 | 140 | 410 | 350 | 120 | 26 | 32 | 45 | 271 | 185 | 157.5 | 167.5 | 70 | 11.5 | 6 | 86 | 215 | M24 | M16 | 32.2 | 22224K 23224K | H3124 H2324 | SR215x14 SR215x10 | 2 1 |

SNG524-619 |

| SNG526 | 115 | 150 | 445 | 380 | 130 | 28 | 35 | 50 | 290 | 190 | 167.5 | 177.5 | 70 | 13 | 6 | 90 | 230 | M24 | M20 | 39.8 | 22226K 23226K | H3126 H2326 | SR230x13 SR230x10 | 2 1 |

SNG526 |

| SNG528 | 125 | 150 | 500 | 420 | 150 | 35 | 42 | 50 | 302 | 205 | 177.5 | 187.5 | 80 | 13 | 6 | 98 | 250 | M30 | M24 | 48.8 | 22228K 23228K | H3128 H2328 | SR250x15 SR250x10 | 2 1 |

SNG528 |

| SNG530 | 135 | 160 | 530 | 450 | 160 | 35 | 42 | &0 | 323 | 220 | 192.5 | 202.5 | 90 | 13.5 | 6 | 106 | 270 | M30 | M24 | 56.5 | 22230K 23230K | H3130 H2330 | SR270x16.5 SR270x10 | 2 1 |

SNG530 |

| SNG532 | 140 | 170 | 550 | 470 | 160 | 35 | 42 | 60 | 344 | 235 | 202.5 | 212.5 | 90 | 13.5 | 6 | 114 | 290 | M30 | M24 | 63.5 | 22232K 23232K | H3132 H2332 | SR290x17 SR290x10 | 2 1 |

SNG532 |

>> Advantages

| KEY WORDS | DESCRIPTIONS |

| MAINTENANCE | Low maintenance due to its self-aligning capabilities |

| LUBRICATION | Fast and easy re-lubrication due to a built-in lubrication hole |

| SELF-ALIGNMENT | Rational self-alignment |

| LOAD | Larger load carrying capacity, relubricable, longer service life of the units |

| SEAL | Efficient, sealing ability of the units with covers is perfect |

| HOUSE | Solid housing, provide maximum rigidity against deformation for any condition |

| LOCK | Easy and positive locking to shaft |

| HEAT-TREATMENT | Special heat-treatment on bearing inner ring prevent causing cracking |

| DEVICE | Unique device to prevent bearing outer ring rotation |

| INTERCHANGEABILITY | Complete interchangeability between bearing and housing |

| INSTALLATION | Easy installation |

| POSITION | Easy positioning for mounting |

>> Manufacturing Processing

| Advantage Manufacturing Processes& Quality Control | We strictly follow the core of quality management process control:

✓ APQP: product quality advance plHangZhou ✓ SPC: Statistical process control ✓ MSA: Measurement system analysis ✓ FMEA: Analysis of potential failure modes and consequences ✓ PPAP: Production part approval procedure |

|

| 01 | Heat Treatment | |

| 02 | Centerless Grinding Machine 11200 (most advanced) | |

| 03 | Automatic P roduction Lines for Raceway | |

| 04 | Automatic P roduction Lines for Raceway | |

| 05 | Ultras onic Cleaning of Rings | |

| 06 | Automatic Ass embly | |

| 07 | Ultras onic Cleaning of Bearings | |

| 08 | Ultras onic Cleaning of Bearings | |

| 09 | Measurement of Bearing Vibration (Acceleration) | |

| 10 | Measurement of Bearing Vibration (Speed) | |

| 11 | Laser Marking | |

| 12 | Automatic Packing | |

>> Packing

>> More Choice

TANN Casting Housing and the Factory

TANN Advantage Bearing Manufacturing Processes

01 Heat Treatment

02 Centerless Grinding Machine 11200 (most advanced)

03 Automatic Production Lines for Raceway

04 Automatic Production Lines for Raceway

05 Ultras onic Cleaning of Rings

06 Automatic Assembly

07 Ultras onic Cleaning of Bearings

08 Automatic Greasing, Seals Pressing

09 Measurement of Bearing Vibration (Acceleration)

10 Measurement of Bearing Vibration (Speed)

11 Laser Marking

12 Automatic Packing

TANN Core of Quality Management Process Control

✓ APQP: product quality advance plHangZhou

✓ SPC: Statistical process control

✓ MSA: Measurement system analysis

✓ FMEA: Analysis of potential failure modes and consequences

✓ PPAP: Production part approval procedure

TANN Packing and Shipping

| Packing | small size& medium size |

plastic buckets/paper-10pcs |

| wrapped with rust-proof paper-10pcs | ||

| color box-1pcs | ||

| large size | wrapped with waterproof winding tape | |

| wooden box | ||

| Pallet | European CZPT pallet | |

| Colesed CZPT wooden pallet | ||

| ISB three-folds pallet | ||

| Shipping | Port of shipment | HangZhou, China |

| Transportation | Sea/ Air/ Road | |

| Price Term | FOB(Usual) | |

| Payment Term | 30% prepayment upone order confirmed, balance T/T before shipment when goods ready. | |

*Could you make a brief introduction to your all series of products?

Yes, we stock and sell factory-warrantied mechanical, electrical, and fluid-driven equipment such as bearings, belts, drives, motors, gears, couplings, clutches and brakes, linear motion, and hydraulics and pneumatics.

*How about your sales group?

At Granville, we understand a competent team makes your job easier, so we have established a group of employees who represent our resourcefulness and commitment to working hard to make sure your unique challenges are handled right the first time.

*What’s your solutions for maximizing customers’ benefits?

Our goal is to have your stock requirements on-hand when you need them. Through our storeroom surveys, in-depth communication, and usage analysis, we can reduce your organization’s inventory cost, supply room costs, and turn-around time.

*What’s your shipping document and documents of payment?

Our usual practice is FOB ZheJiang & T/T, and we could adjust them for your requirements.

*What’s the most convenient way to get your free quotation?

Please contact Stacy with your requirements (or Copy the contents of the table and fill in it with your information)

{Hi! This is Stacy from Granville, let me know if you have any requirements for our products or services. Have a nice day! 🙂

>> You May Like

| You May Like(No.) | |

| 1 | UC |

| 2 | SA |

| 3 | SAPFT |

| 4 | H |

| 5 | UCP |

| 6 | UCF |

| 7 | UCFC |

| 8 | UCFL |

| 9 | UCFA |

| 10 | UCT |

| 11 | UCPH |

| 12 | SN |

Please feel free to get information from Granville:)

Manufacturing

Advance automatic lines

Granville takes her every effort in purchasing the most advanced bearing process equipment, CNC automatic facilities are widely used in the factory and we are keep investing to improve more.

Comprehensive

Full range bearing & units

We provide a strong full range of products, including:

Radial ball bearings

Pillow block and wide range of housed units

Electric motor and components

One-stop partnerships products

Premium Quality

Quality control from beginning

All products are manufactured exclusively by companies with ISO 9001:2008 certified Quality Systems which use state-of-the-art machines. The quality path starts from the beginning to delivery and goods’ quality is trackable.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Aligning Bearing |

|---|---|

| Separated: | Separated |

| Feature: | Vacuum, Magnetically, Low Temperature, Corrosion Resistant, High Temperature, High Speed |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | Order Sample SNG500 Series Split Plummer Block

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What is the typical price range for block bearings?

The price range for block bearings can vary depending on various factors such as the bearing type, size, materials, quality, and the supplier or manufacturer. Here’s a detailed explanation of the typical price range for block bearings:

1. Standard Block Bearings: Standard block bearings, commonly used in many industrial applications, are generally more affordable compared to specialized or high-performance variants. The price range for standard block bearings typically varies from a few dollars to several tens of dollars per bearing, depending on factors such as the bearing size, load capacity, and quality of construction.

2. Specialized Block Bearings: Specialized block bearings designed for specific applications or industries may have a higher price range due to their unique features, materials, or performance characteristics. For example, block bearings designed for high-speed applications, extreme temperatures, or corrosive environments may fall into a higher price range. Prices for specialized block bearings can range from tens of dollars to several hundred dollars per bearing, depending on the specific requirements and performance specifications.

3. High-Precision or Custom Block Bearings: High-precision block bearings or custom-designed bearings, which are manufactured to very tight tolerances or tailored to specific machinery requirements, can have a higher price range. These bearings often involve additional engineering, manufacturing, or quality control processes, which contribute to their higher cost. The price range for high-precision or custom block bearings can vary significantly, ranging from hundreds of dollars to several thousand dollars per bearing.

It’s important to note that the prices mentioned above are general estimates and can vary based on factors such as geographical location, market demand, quantity ordered, and supplier-specific pricing policies. Additionally, prices may also be subject to fluctuations over time due to factors such as raw material costs, manufacturing expenses, and market conditions.

When considering the price of block bearings, it’s essential to balance cost with quality and performance requirements. Opting for reputable suppliers or manufacturers known for their reliability and product quality is advisable to ensure that the block bearings meet the desired specifications and provide long-term value.

Are there different grades or types of block bearings?

Yes, there are different grades and types of block bearings available to suit various applications and operating conditions. Block bearings, also known as pillow block bearings or plummer block bearings, come in a range of designs and configurations to accommodate different shaft sizes, loads, speeds, and environmental factors. Here are some common grades and types of block bearings:

1. Standard Duty Block Bearings: Standard duty block bearings are commonly used in general applications with moderate loads and speeds. They are designed to provide reliable support for rotating shafts in a wide range of industries and machinery.

2. Heavy Duty Block Bearings: Heavy duty block bearings are specifically designed to handle higher loads and more demanding operating conditions compared to standard duty bearings. They are suitable for applications that involve heavy loads, shock loads, or high-speed rotation.

3. High-Temperature Block Bearings: High-temperature block bearings are designed to withstand elevated temperatures without compromising their performance or longevity. They are commonly used in applications where the operating temperatures exceed the capabilities of standard bearings.

4. Corrosion-Resistant Block Bearings: Corrosion-resistant block bearings are made from materials or coatings that provide protection against corrosive environments. These bearings are used in industries such as food processing, chemical processing, or marine applications where exposure to moisture, chemicals, or other corrosive agents is a concern.

5. Split Block Bearings: Split block bearings feature a housing that can be split into two or more pieces, allowing for easier installation and maintenance. They are often used in applications where it is difficult to access or remove the bearing without disassembling other components.

6. Self-Aligning Block Bearings: Self-aligning block bearings have a spherical outer diameter that allows for self-alignment, compensating for minor shaft misalignments. These bearings are suitable for applications where shaft deflection or misalignment is expected.

7. Flange Block Bearings: Flange block bearings have a flanged housing that provides additional support and stability. They are commonly used in applications where the bearing needs to be bolted to a structure or where space constraints limit the use of traditional block bearings.

8. Specialty Block Bearings: There are also specialty block bearings designed for specific applications or industries. For example, there are block bearings optimized for high-speed applications, extreme temperatures, vacuum environments, or specific industries like mining or agriculture.

It’s important to consult the manufacturer’s specifications and guidelines to select the appropriate grade and type of block bearing for a specific application. Factors such as load capacity, speed, temperature, environmental conditions, and maintenance requirements should be taken into consideration to ensure optimal performance and longevity of the bearing.

Where can I purchase block bearings?

If you are looking to purchase block bearings, there are several options available to you. Here’s a detailed explanation of where you can purchase block bearings:

- Local Industrial Suppliers: One of the most convenient options is to check with local industrial suppliers or distributors in your area. These suppliers typically carry a wide range of bearings, including block bearings, and can provide you with the necessary guidance and support in selecting the right product for your specific application. You can search online directories or use search engines to find industrial suppliers near you.

- Bearing Manufacturers: Many bearing manufacturers have their own sales channels and online platforms where you can directly purchase block bearings. Some well-known bearing manufacturers include SKF, Timken, NSK, NTN, and FAG. Visiting the manufacturers’ websites will provide you with information on their authorized distributors, online stores, or contact details to inquire about purchasing options.

- Online Marketplaces: Online marketplaces like Amazon, eBay, and Alibaba offer a wide selection of block bearings from various sellers and suppliers. These platforms allow you to compare prices, read customer reviews, and choose from different brands and models. However, it’s important to ensure that you are purchasing from reputable sellers with positive ratings and reviews.

- Specialized Bearing Suppliers: There are specialized bearing suppliers that focus specifically on bearings and related products. These suppliers often have a comprehensive inventory of different types of bearings, including block bearings. They may have online stores or physical locations where you can make a purchase. Searching online for “specialized bearing suppliers” or “bearing distributors” will help you find such suppliers.

- Industrial Trade Shows and Exhibitions: Attending industrial trade shows and exhibitions related to machinery, bearings, or specific industries can provide an opportunity to connect with multiple suppliers and manufacturers in one place. These events often have exhibitors showcasing their products, including block bearings, and you can discuss your requirements directly with the representatives to make a purchase or gather information for future procurement.

- Local Machine Shops: Local machine shops or maintenance and repair service providers may stock block bearings for immediate purchase. These establishments often have a range of bearings available for quick replacement or repair needs. It’s worth checking with local machine shops in your area to inquire about their bearing inventory and purchasing options.

When purchasing block bearings, it’s important to consider factors such as the specific requirements of your application, the load capacity and speed rating of the bearing, the compatibility with your shaft diameter, and the quality and reputation of the supplier or manufacturer. It’s advisable to consult with experts or technical support from the supplier to ensure you select the right bearing for your needs.

Remember to compare prices, check for warranties or guarantees, and consider the shipping or delivery options before making a purchase decision.

editor by CX 2024-05-09

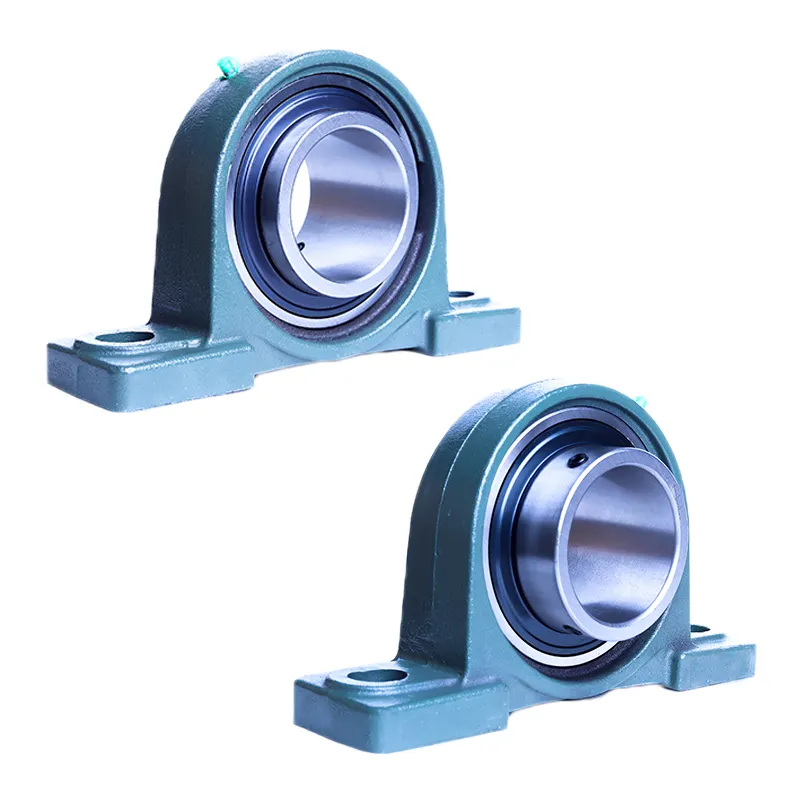

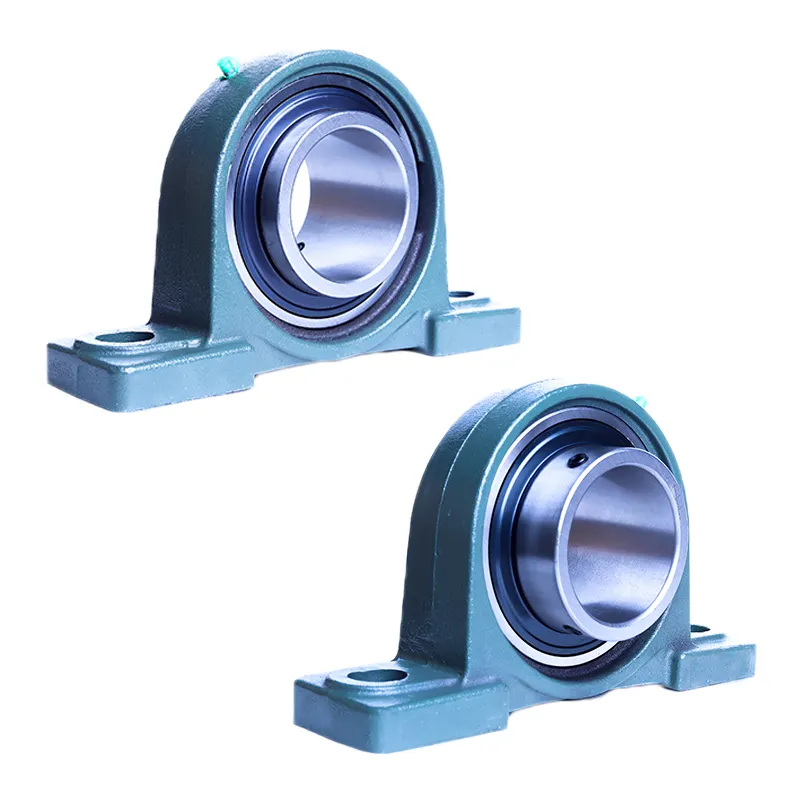

China OEM High Quality Insert Pillow Block Ball Bearing UC316 Machine Used Block Bearing bearing engineering

Product Description

ABOUT US

Founded in 2000, it has become a professional bearing manufacturer with advanced bearing production technology and the most advanced CNC equipment in China. The whole production process from raw materials to finished products, from design to manufacturing, is produced in accordance with national standards. The main production: spherical roller bearings, insert bearings, housings, deep groove ball bearings, adapter sleeves, and cylindrical roller bearings, with an annual output of more than 5 million sets, with an output value of more than 40 million yuan. The quality of the finished product meets the national inspection standards and has stable reliability.

Our Bearing Advantage:

1. Free Sample bearing;

2.ISO Standard;

3. Bearing Small order accepted;

4. In Stock bearing;

5. OEM/ODM bearing service;

6. Professional: more than 20 years of manufacture bearing;

7. Customized bearing, Customer’s bearing drawing or samples accepted;

8. Competitive price bearing: factory outlet.

KOYO CZPT CZPT UC Series Insert Roller Ball Bearings for Spare Parts

Product Description

Good quality ball bearings UC insert bearing

1.Prodcut name : UC ball bearing

2.Broe diameter:20mm-200mm

3.Precision level:P5,P6,P0

4.Sealing form:OPEN,Z,ZZ,RS,2RS,2RZ.N

5.Package:Wooden packing or pallet packing or according to the customer’s requirements.

6.OEM is available

Parameters of Bearing

More details of UC211-34 UC, UG, UCP, UCFL, UCF, SA, SB, SN, UT Pillow Block Bearing/Insert Bearing

| BearingUint No. | Shaft Dia d | Dimensinons(mm) | Bolt Used | Bearing No. | Housing No. | Housing Wt (kg) |

|||||||||||||

| h | a | e | b | S2 | S1 | g | w | t | Z | Bi | n | (mm) | (in) | ||||||

| (in) | (mm) | ||||||||||||||||||

| UCP201-8 | 1/2 | 30.2 | 127 | 95 | 38 | 19 | 13 | 14 | 62 | 2 | 51 | 31 | 12.7 | M10 | 3/8 | UC201-8 | P203 | 0.33 | |

| UCP202-9 | 9/16 | UC202-9 | |||||||||||||||||

| UCP202-10 | 5/8 | UC202-10 | |||||||||||||||||

| UCP203-11 | 11/16 | UC203-11 | |||||||||||||||||

| UCP201 | 12 | UC201 | |||||||||||||||||

| UCP202 | 15 | UC202 | |||||||||||||||||

| UCP203 | 17 | UC203 | |||||||||||||||||

| UCP204-12 | 3/4 | 33.3 | 127 | 95 | 38 | 19 | 13 | 14 | 65 | 2 | 51 | 31 | 12.7 | M10 | 3/8 | UC204-12 | P204 | 0.46 | |

| UCP204 | 20 | UC204 | |||||||||||||||||

| UCP205-13 | 13/16 | 25 | 36.5 | 140 | 105 | 38 | 19 | 13 | 15 | 71 | 2 | 57 | 34.1 | 14.3 | M10 | 3/8 | UC205-13 | P205 | 0.60 |

| UCP205-14 | 7/8 | UC205-14 | |||||||||||||||||

| UCP205-15 | 15/16 | UC205-15 | |||||||||||||||||

| UCP205-16 | 1 | UC205-16 | |||||||||||||||||

| UCP205 | UC205 | ||||||||||||||||||

| UCP206-17 | 1-1/16 | 30 | 42.9 | 165 | 121 | 48 | 21 | 17 | 17 | 83 | 2 | 62 | 38.1 | 15.9 | M14 | 1/2 | UC206-17 | P206 | 0.97 |

| UCP206-18 | 1-1/8 | UC206-18 | |||||||||||||||||

| UCP206-19 | 1-3/16 | UC206-19 | |||||||||||||||||

| UCP206-20 | 1-1/4 | UC206-20 | |||||||||||||||||

| UCP206 | UC206 | ||||||||||||||||||

| UCP207-20 | 1-1/4 | 35 | 47.6 | 167 | 127 | 48 | 21 | 17 | 18 | 93 | 3 | 72 | 42.9 | 17.5 | M14 | 1/2 | UC207-20 | P207 | 1.00 |

| UCP207-21 | 1-5/16 | UC207-21 | |||||||||||||||||

| UCP207-22 | 1-3/8 | UC207-22 | |||||||||||||||||

| UCP207-23 | 1-7/16 | UC207-23 | |||||||||||||||||

| UCP207 | UC207 | ||||||||||||||||||

| UCP208-24 | 1-1/2 | 40 | 49.2 | 184 | 137 | 54 | 21 | 17 | 18 | 98 | 3 | 82 | 49.2 | 19.0 | M14 | 1/2 | UC208-24 | P208 | 1.30 |

| UCP208-25 | 1-9/16 | UC208-25 | |||||||||||||||||

| UCP208 | UC208 | ||||||||||||||||||

| UCP209-26 | 1-5/8 | 45 | 54 | 190 | 146 | 54 | 21 | 17 | 20 | 106 | 3 | 82 | 49.2 | 19.0 | M14 | 1/2 | UC209-26 | P209 | 1.40 |

| UCP209-27 | 1-11/16 | UC209-27 | |||||||||||||||||

| UCP209-28 | 1-3/4 | UC209-28 | |||||||||||||||||

| UCP209 | UC209 | ||||||||||||||||||

| UCP210-29 | 1-13/16 | 50 | 57.2 | 206 | 159 | 60 | 25 | 20 | 21 | 114 | 3 | 87 | 51.6 | 19.0 | M16 | 5/8 | UC210-29 | P210 | 1.83 |

| UCP210-30 | 1-7/8 | UC210-30 | |||||||||||||||||

| UCP210-31 | 1-15/16 | UC210-31 | |||||||||||||||||

| UCP210-32 | 2 | UC210-32 | |||||||||||||||||

| UCP210 | UC210 | ||||||||||||||||||

| UCP211-32 | 2 | 55 | 63.5 | 219 | 171 | 60 | 25 | 20 | 23 | 126 | 4 | 92 | 55.6 | 22.2 | M16 | 5/8 | UC211-32 | P211 | 2.4 |

| UCP211-33 | 2-1/16 | UC211-33 | |||||||||||||||||

| UCP211-34 | 2-1/8 | UC211-34 | |||||||||||||||||

| UCP211-35 | 2-3/16 | UC211-35 | |||||||||||||||||

| UCP211 | UC211 | ||||||||||||||||||

| UCP212-36 | 2-1/4 | 60 | 69.8 | 241 | 184 | 70 | 25 | 20 | 25 | 138 | 4 | 102 | 65.1 | 25.4 | M16 | 5/8 | UC212-36 | P212 | 2.8 |

| UCP212-37 | 2-5/16 | UC212-37 | |||||||||||||||||

| UCP212-38 | 2-3/8 | UC212-38 | |||||||||||||||||

| UCP212-39 | 2-7/16 | UC212-39 | |||||||||||||||||

| UCP212 | UC212 | ||||||||||||||||||

| UCP213-40 | 2-1/2 | 65 | 76.2 | 265 | 203 | 70 | 29 | 25 | 27 | 151 | 4 | 107 | 65.1 | 25.4 | M20 | 3/4 | UC213-40 | P213 | 3.5 |

| UCP213-41 | 2-9/16 | UC213-41 | |||||||||||||||||

| UCP213 | UC213 | ||||||||||||||||||

| UCP214-42 | 2-5/8 | 70 | 79.4 | 266 | 210 | 72 | 31 | 25 | 27 | 157 | 74.6 | 30.2 | M20 | 3/4 | UC214-42 | P214 | 4.45 | ||

| UCP214-43 | 2-11/16 | UC214-43 | |||||||||||||||||

| UCP214-44 | 2-3/4 | UC214-44 | |||||||||||||||||

| UCP214 | UC214 | ||||||||||||||||||

| UCP215-45 | 2-13/16 | 75 | 82.6 | 275 | 217 | 74 | 31 | 25 | 28 | 163 | 77.8 | 33.3 | M20 | 3/4 | UC215-45 | P215 | 4.9 | ||

| UCP215-46 | 2-7/8 | UC215-46 | |||||||||||||||||

| UCP215-47 | 2-15/16 | UC215-47 | |||||||||||||||||

| UCP215-48 | 3 | UC215-48 | |||||||||||||||||

| UCP215 | UC215 | ||||||||||||||||||

| UCP216-50 | 3-1/8 | 80 | 88.9 | 292 | 232 | 78 | 31 | 25 | 30 | 175 | 82.6 | 33.3 | M20 | 3/4 | UC216-50 | P216 | 5.8 | ||

| UCP216 | UC216 | ||||||||||||||||||

| UCP217-52 | 3-1/4 | 85 | 95.2 | 310 | 247 | 83 | 31 | 25 | 32 | 187 | 85.7 | 34.1 | M20 | 3/4 | UC217-52 | P217 | 6.9 | ||

| UCP217 | UC217 | ||||||||||||||||||

| UCP218-56 | 3-1/2 | 90 | 101.6 | 327 | 262 | 88 | 33 | 27 | 33 | 200 | 96.0 | 39.7 | M22 | 7/8 | UC218-56 | P218 | 8.10 | ||

| Bearing Unit NO. |

Shaft Dia d | Dimensions(mm) | Bolt Used | Bearing No. | Housing No. | Housing Wt (kg) |

|||||||||||

| (in) | (mm) | h | a | e | b | s2 | s1 | g | w | Bi | n | (in) | (mm) | ||||

| UCP305-14 UCP305-15 UCP305-16 UCP305 |

7/8 15/16 1 |

25 | 45 | 175 | 132 | 45 | 20 | 17 | 15 | 85 | 38 | 15 | 1/2 | M14 | UC305-14 UC305-15 UC305-16 UC305 |

P305 | 0.90 |

| UCP306-18 UCP306-19 UCP306 |

1-1/8 1-3/16 |

30 | 50 | 180 | 140 | 50 | 20 | 17 | 18 | 95 | 43 | 17 | 1/2 | M14 | UC306-18 UC306-19 UC306 |

P306 | 1.10 |

| UCP307-20 UCP307-21 UCP307-22 UCP307-23 UCP307 |

1-1/4 1-5/16 1-3/8 1-7/16 |

35 | 56 | 210 | 160 | 56 | 25 | 17 | 20 | 106 | 48 | 19 | 1/2 | M14 | UC307-20 UC307-21 UC307-22 UC307-23 UC307 |

P307 | 1.95 |

| UCP308-24 UCP308-25 UCP308 |

1-1/2 1-9/16 |

40 | 60 | 220 | 170 | 60 | 27 | 17 | 22 | 116 | 52 | 19 | 1/2 | M14 | UC308-24 UC308-25 UC308 |

P308 | 2.20 |

| UCP309-26 UCP309-27 UCP309-28 UCP309 |

1-5/8 1-11/16 1-3/4 |

45 | 67 | 245 | 190 | 67 | 30 | 20 | 24 | 129 | 57 | 22 | 5/8 | M16 | UC309-26 UC309-27 UC309-28 UC309 |

P309 | 3.30 |

| UCP310-30 UCP310-31 UCP310 |

1-7/8 1-15/16 |

50 | 75 | 275 | 212 | 75 | 35 | 20 | 27 | 143 | 61 | 22 | 5/8 | M16 | UC310-30 UC310-31 UC310 |

P310 | 4.80 |

| UCP311-32 UCP311-34 UCP311-35 UCP311 |

2 2-3/8 2-3/16 |

55 | 80 | 310 | 236 | 80 | 38 | 20 | 30 | 154 | 66 | 25 | 5/8 | M16 | UC311-32 UC311-34 UC311-35 UC311 |

P311 | 5.30 |

| UCP312-36 UCP312-38 UCP312-39 UCP312 |

2-1/4 2-3/8 2-7/16 |

60 | 85 | 330 | 250 | 85 | 38 | 25 | 32 | 165 | 71 | 26 | 3/4 | M20 | UC312-36 UC312-38 UC312-39 UC312 |

P312 | 6.30 |

| UCP313-40 UCP313 |

2-1/2 | 65 | 90 | 340 | 260 | 90 | 38 | 25 | 33 | 176 | 75 | 30 | 3/4 | M20 | UC313-40 UC313 |

P313 | 8.00 |

| UCP314-44 UCP314 |

2-3/4 | 70 | 95 | 360 | 280 | 90 | 40 | 27 | 35 | 187 | 78 | 33 | 7/8 | M22 | UC314-44 UC314 |

P314 | 8.30 |

| UCP315-48 UCP315 |

3 | 75 | 100 | 380 | 290 | 100 | 40 | 27 | 35 | 198 | 82 | 32 | 7/8 | M22 | UC315-48 UC315 |

P315 | 9.50 |

| UCP316-50 UCP316 |

3-1/8 | 80 | 106 | 400 | 300 | 110 | 40 | 27 | 40 | 210 | 86 | 34 | 7/8 | M22 | UC316-50 UC315 |

P316 | 12.50 |

| UCP317-52 UCP317 |

3-1/4 | 85 | 112 | 420 | 320 | 110 | 45 | 33 | 40 | 220 | 96 | 40 | 1 | M27 | UC317-52 UC317 |

P317 | 14.50 |

| UCP318-56 UCP318 |

3-1/2 | 90 | 118 | 430 | 330 | 110 | 45 | 33 | 45 | 235 | 96 | 40 | 1 | M27 | UC318-56 UC318 |

P318 | 20.40 |

| UCP319-60 UCP319 |

3-3/4 | 95 | 125 | 470 | 360 | 120 | 50 | 36 | 45 | 250 | 103 | 41 | 1-1/8 | M30 | UC319-60 UC319 |

P319 | 22.30 |

| UCP320-64 UCP320 |

4 | 100 | 140 | 490 | 380 | 120 | 50 | 36 | 50 | 275 | 108 | 42 | 1-1/8 | M30 | UC320-64 UC320 |

P320 | 25.00 |

| UCP321 | 105 | 140 | 490 | 380 | 120 | 50 | 36 | 50 | 280 | 112 | 44 | 1-1/8 | M30 | UC321 | P321 | 24.00 | |

| UCP322 | 110 | 150 | 520 | 400 | 140 | 55 | 40 | 55 | 300 | 117 | 46 | M33 | UC322 | P322 | 27.50 | ||

| UCP324 | 120 | 160 | 570 | 450 | 140 | 55 | 40 | 65 | 320 | 126 | 51 | M33 | UC324 | P324 | 32.30 | ||

| UCP326 | 130 | 180 | 600 | 480 | 140 | 55 | 40 | 75 | 355 | 135 | 54 | M33 | UC326 | P326 | 41.00 | ||

| UCP328 | 140 | 200 | 620 | 500 | 140 | 55 | 40 | 75 | 390 | 145 | 59 | M33 | UC328 | P328 | 50.00 | ||

| BearingUint No. | Shaft Dia d | Dimensinons(mm) | Bolt Used | Bearing No. | Housing No. | Housing Wt (kg) |

|||||||||||

| h | a | e | b | S2 | S1 | g | w | Bi | n | (mm) | (in) | ||||||

| (in) | (mm) | ||||||||||||||||

| UCPE201-8 | 1/2 | 30.2 | 124 | 95 | 31 | 15 | 11 | 14 | 57.1 | 26 | 10 | M8 | 5/16 | UCW201-8 | PE203 | 0.45 | |

| UCPE202-9 | 9/16 | UCW202-9 | |||||||||||||||

| UCPE202-10 | 5/8 | UCW202-10 | |||||||||||||||

| UCPE203-11 | 11/16 | UCW203-11 | |||||||||||||||

| UCPE201 | 12 | UCW201 | |||||||||||||||

| UCPE202 | 15 | UCW202 | |||||||||||||||

| UCPE203 | 17 | UCW203 | |||||||||||||||

| UCPE204-12 | 3/4 | 33.3 | 127 | 95 | 38 | 16 | 13 | 15 | 65 | 31 | 12.7 | M10 | 3/8 | UC204-12 | PE204 | 0.65 | |

| UCPE204 | 20 | UC204 | |||||||||||||||

| UCPE205-13 | 13/16 | 25 | 36.6 | 140 | 105 | 38 | 16 | 13 | 16 | 70 | 34 | 14.3 | M10 | 3/8 | UC205-13 | PE205 | 0.75 |

| UCPE205-14 | 7/8 | UC205-14 | |||||||||||||||

| UCPE205-15 | 15/16 | UC205-15 | |||||||||||||||

| UCPE205-16 | 1 | UC205-16 | |||||||||||||||

| UCPE205 | UC205 | ||||||||||||||||

| UCPE206-17 | 1-1/16 | 30 | 42.9 | 165 | 121 | 48 | 21 | 17 | 18 | 83 | 38.1 | 15.9 | M14 | 1/2 | UC206-17 | PE206 | 1.15 |

| UCPE206-18 | 1-1/8 | UC206-18 | |||||||||||||||

| UCPE206-19 | 1-3/16 | UC206-19 | |||||||||||||||

| UCPE206-20 | 1-1/4 | UC206-20 | |||||||||||||||

| UCPE206 | UC206 | ||||||||||||||||

| UCPE207-20 | 1-1/4 | 35 | 47.6 | 167 | 127 | 48 | 21 | 17 | 19 | 94 | 42.9 | 17.5 | M14 | 1/2 | UC207-20 | PE207 | 1.30 |

| UCPE207-21 | 1-5/16 | UC207-21 | |||||||||||||||

| UCPE207-22 | 1-3/8 | UC207-22 | |||||||||||||||

| UCPE207-23 | 1-7/16 | UC207-23 | |||||||||||||||

| UCPE207 | UC207 | ||||||||||||||||

| UCPE208-24 | 1-1/2 | 40 | 49.2 | 137 | 54 | 25 | 17 | 19 | 100 | 49.2 | 19.0 | M14 | 1/2 | UC208-24 | PE208 | 1.50 | |

| UCPE208-25 | 1-9/16 | UC208-25 | |||||||||||||||

| UCPE208 | UC208 | ||||||||||||||||

| UCPE209-26 | 1-5/8 | 45 | 54 | 190 | 146 | 54 | 25 | 17 | 20 | 108 | 49.2 | 19.0 | M14 | 1/2 | UC209-26 | 1.75 | |

| UCPE209-27 | 1-11/16 | UC209-27 | |||||||||||||||

| UCPE209-28 | 1-3/4 | UC209-28 | |||||||||||||||

| UCPE209 | UC209 | ||||||||||||||||

| UCPE210-29 | 1-13/16 | 50 | 57.2 | 206 | 159 | 60 | 25 | 20 | 22 | 114 | 51.6 | 19.0 | M16 | 5/8 | UC210-29 | PE210 | 2.35 |

| UCPE210-30 | 1-7/8 | UC210-30 | |||||||||||||||

| UCPE210-31 | 1-15/16 | UC210-31 | |||||||||||||||

| UCPE210-32 | 2 | UC210-32 | |||||||||||||||

| UCPE210 | UC210 | ||||||||||||||||

| UCPE211-32 | 2 | 55 | 63.5 | 219 | 171 | 60 | 25 | 20 | 22 | 126 | 55.6 | 22.2 | M16 | 5/8 | UC211-32 | PE211 | 2.60 |

| UCPE211-33 | 2-1/16 | UC211-33 | |||||||||||||||

| UCPE211-34 | 2-1/8 | UC211-34 | |||||||||||||||

| UCPE211-35 | 2-3/16 | UC211-35 | |||||||||||||||

| UCPE211 | UC211 | ||||||||||||||||

| UCPE212-36 | 2-1/4 | 60 | 69.8 | 241 | 184 | 70 | 25 | 20 | 25 | 138 | 65.1 | 25.4 | M16 | 5/8 | UC212-36 | PE212 | 4.00 |

| UCPE212-37 | 2-5/16 | UC212-37 | |||||||||||||||

| UCPE212-38 | 2-3/8 | UC212-38 | |||||||||||||||

| UCPE212-39 | 2-7/16 | UC212-39 | |||||||||||||||

| UCPE212 | UC212 | ||||||||||||||||

| UCPE213-40 | 2-1/2 | 65 | 76.2 | 265 | 203 | 70 | 29 | 25 | 27 | 65.1 | 25.4 | M20 | 3/4 | UC213-40 | PE213 | 4.77 | |

| UCPE213-41 | 2-9/16 | UC213-41 | |||||||||||||||

| UCPE213 | UC213 | ||||||||||||||||

| UCPE214-42 | 2-5/8 | 70 | 79.4 | 266 | 210 | 72 | 31 | 25 | 27 | 156 | 74.6 | 30.2 | M20 | 3/4 | UC214-42 | PE214 | 5.30 |

| UCPE214-43 | 2-11/16 | UC214-43 | |||||||||||||||

| UCPE214-44 | 2-3/4 | UC214-44 | |||||||||||||||

| UCPE214 | UC214 | ||||||||||||||||

| UCPE215-45 | 2-13/16 | 75 | 82.6 | 275 | 217 | 74 | 31 | 25 | 28 | 163 | 77.8 | 33.3 | M20 | 3/4 | UC215-45 | PE215 | 6.00 |

| UCPE215-46 | 2-7/8 | UC215-46 | |||||||||||||||

| UCPE215-47 | 2-15/16 | UC215-47 | |||||||||||||||

| UCPE215-48 | 3 | UC215-48 | |||||||||||||||

| UCPE215 | UC215 | ||||||||||||||||

Our packing:

* Industrial pakage+outer carton+pallets

* sigle box+outer carton+pallets

* Tube package+middle box+outer carton+pallets

* According to your requirments

Company Profile

ABOUT US

BEARING MANUFACTURE

1. 20+ years of experience in manufacturing bearing;

2.Annual output value of more than 40 million yuan;

3.Passed the ISO9001 international quality certification system;

4.160 sets imported production equipments;

5.Professional sales team.

We have been engaged in foreign trade for more than 6 years and are well-known enterprises in ZheJiang Province. The fixed assets of the machine are more than 2 million US dollars, and the annual foreign trade sales volume exceeds 2 million US dollars.

We have extensive cooperation with countries in Asia, Europe, and the Americas. Including Russia, Ukraine, elaruBelaruss, Kazakhstan, Uzbekistan, Tajikistan, Spain, Mexico,India, Pakistan, Turkey, Vietnam and other industrial areas.

Export to many countries

HangZhou Jinrui Bearing Co., Ltd. not only has customers in many industries in China, but the company’s products are also exported to India, Southeast Asia, the Middle East, Europe and the United States and other countries. It has independent export rights and more than 10 years of foreign trade export experience.

FAQ

SAMPLES

1.Samples quantity: 1-10 pcs are available.

2.Free samples: It depends on the model NO., material and quantity. Some of the bearings samples need client to pay

samples charge and shipping cost.

3.It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1.MOQ: 10 pcs mix different standard bearings.

2.MOQ: 3000 pcs customized your brand bearings.

OEM POLICY

1.We can printing your brand (logo,artwork)on the shield or laser engraving your brand on the shield.

2.We can custom your packaging according to your design

3.All copyright own by clients and we promised don’t disclose any info.

SUPORT

Please visit our bearings website, we strongly encourge that you can communicate with us through email,thanks!

We have all kinds of bearings, just tell me your item number and quantity,best price will be offered to you soon

The material of the bearings, precision rating, seals type,OEM service,etc, all of them we can make according to your requirement.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | Small and Medium-Sized (60-115mm) |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Separated |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What is the typical price range for block bearings?

The price range for block bearings can vary depending on various factors such as the bearing type, size, materials, quality, and the supplier or manufacturer. Here’s a detailed explanation of the typical price range for block bearings:

1. Standard Block Bearings: Standard block bearings, commonly used in many industrial applications, are generally more affordable compared to specialized or high-performance variants. The price range for standard block bearings typically varies from a few dollars to several tens of dollars per bearing, depending on factors such as the bearing size, load capacity, and quality of construction.

2. Specialized Block Bearings: Specialized block bearings designed for specific applications or industries may have a higher price range due to their unique features, materials, or performance characteristics. For example, block bearings designed for high-speed applications, extreme temperatures, or corrosive environments may fall into a higher price range. Prices for specialized block bearings can range from tens of dollars to several hundred dollars per bearing, depending on the specific requirements and performance specifications.

3. High-Precision or Custom Block Bearings: High-precision block bearings or custom-designed bearings, which are manufactured to very tight tolerances or tailored to specific machinery requirements, can have a higher price range. These bearings often involve additional engineering, manufacturing, or quality control processes, which contribute to their higher cost. The price range for high-precision or custom block bearings can vary significantly, ranging from hundreds of dollars to several thousand dollars per bearing.

It’s important to note that the prices mentioned above are general estimates and can vary based on factors such as geographical location, market demand, quantity ordered, and supplier-specific pricing policies. Additionally, prices may also be subject to fluctuations over time due to factors such as raw material costs, manufacturing expenses, and market conditions.

When considering the price of block bearings, it’s essential to balance cost with quality and performance requirements. Opting for reputable suppliers or manufacturers known for their reliability and product quality is advisable to ensure that the block bearings meet the desired specifications and provide long-term value.

Are there different grades or types of block bearings?

Yes, there are different grades and types of block bearings available to suit various applications and operating conditions. Block bearings, also known as pillow block bearings or plummer block bearings, come in a range of designs and configurations to accommodate different shaft sizes, loads, speeds, and environmental factors. Here are some common grades and types of block bearings:

1. Standard Duty Block Bearings: Standard duty block bearings are commonly used in general applications with moderate loads and speeds. They are designed to provide reliable support for rotating shafts in a wide range of industries and machinery.

2. Heavy Duty Block Bearings: Heavy duty block bearings are specifically designed to handle higher loads and more demanding operating conditions compared to standard duty bearings. They are suitable for applications that involve heavy loads, shock loads, or high-speed rotation.

3. High-Temperature Block Bearings: High-temperature block bearings are designed to withstand elevated temperatures without compromising their performance or longevity. They are commonly used in applications where the operating temperatures exceed the capabilities of standard bearings.

4. Corrosion-Resistant Block Bearings: Corrosion-resistant block bearings are made from materials or coatings that provide protection against corrosive environments. These bearings are used in industries such as food processing, chemical processing, or marine applications where exposure to moisture, chemicals, or other corrosive agents is a concern.

5. Split Block Bearings: Split block bearings feature a housing that can be split into two or more pieces, allowing for easier installation and maintenance. They are often used in applications where it is difficult to access or remove the bearing without disassembling other components.

6. Self-Aligning Block Bearings: Self-aligning block bearings have a spherical outer diameter that allows for self-alignment, compensating for minor shaft misalignments. These bearings are suitable for applications where shaft deflection or misalignment is expected.

7. Flange Block Bearings: Flange block bearings have a flanged housing that provides additional support and stability. They are commonly used in applications where the bearing needs to be bolted to a structure or where space constraints limit the use of traditional block bearings.

8. Specialty Block Bearings: There are also specialty block bearings designed for specific applications or industries. For example, there are block bearings optimized for high-speed applications, extreme temperatures, vacuum environments, or specific industries like mining or agriculture.

It’s important to consult the manufacturer’s specifications and guidelines to select the appropriate grade and type of block bearing for a specific application. Factors such as load capacity, speed, temperature, environmental conditions, and maintenance requirements should be taken into consideration to ensure optimal performance and longevity of the bearing.

Where can I purchase block bearings?

If you are looking to purchase block bearings, there are several options available to you. Here’s a detailed explanation of where you can purchase block bearings:

- Local Industrial Suppliers: One of the most convenient options is to check with local industrial suppliers or distributors in your area. These suppliers typically carry a wide range of bearings, including block bearings, and can provide you with the necessary guidance and support in selecting the right product for your specific application. You can search online directories or use search engines to find industrial suppliers near you.

- Bearing Manufacturers: Many bearing manufacturers have their own sales channels and online platforms where you can directly purchase block bearings. Some well-known bearing manufacturers include SKF, Timken, NSK, NTN, and FAG. Visiting the manufacturers’ websites will provide you with information on their authorized distributors, online stores, or contact details to inquire about purchasing options.

- Online Marketplaces: Online marketplaces like Amazon, eBay, and Alibaba offer a wide selection of block bearings from various sellers and suppliers. These platforms allow you to compare prices, read customer reviews, and choose from different brands and models. However, it’s important to ensure that you are purchasing from reputable sellers with positive ratings and reviews.

- Specialized Bearing Suppliers: There are specialized bearing suppliers that focus specifically on bearings and related products. These suppliers often have a comprehensive inventory of different types of bearings, including block bearings. They may have online stores or physical locations where you can make a purchase. Searching online for “specialized bearing suppliers” or “bearing distributors” will help you find such suppliers.

- Industrial Trade Shows and Exhibitions: Attending industrial trade shows and exhibitions related to machinery, bearings, or specific industries can provide an opportunity to connect with multiple suppliers and manufacturers in one place. These events often have exhibitors showcasing their products, including block bearings, and you can discuss your requirements directly with the representatives to make a purchase or gather information for future procurement.

- Local Machine Shops: Local machine shops or maintenance and repair service providers may stock block bearings for immediate purchase. These establishments often have a range of bearings available for quick replacement or repair needs. It’s worth checking with local machine shops in your area to inquire about their bearing inventory and purchasing options.

When purchasing block bearings, it’s important to consider factors such as the specific requirements of your application, the load capacity and speed rating of the bearing, the compatibility with your shaft diameter, and the quality and reputation of the supplier or manufacturer. It’s advisable to consult with experts or technical support from the supplier to ensure you select the right bearing for your needs.

Remember to compare prices, check for warranties or guarantees, and consider the shipping or delivery options before making a purchase decision.

editor by CX 2024-05-08

China OEM Linear Motion Sliding Block Linear Slide Unit Bearing Sc25uu Scj25uu Scs25uu SMA25uu bearing air

Product Description

linear motion sliding block linear slide unit bearing SC25UU SCJ25UU SCS25UU SMA25UU

Linear Bearing widely used in many precision equipment,like electronic equipment, tension tester and digital coordinate measurement equipment etc.

Linear Bearing widely used in many machines,like multi-axis machine, punch, tool

grinding machine, automatic cutting machine, printer, card sorting machine, ShiPinBao installed the sliding parts such as industrial machinery.

Welcome to make inquiry!

Bearing:Linear Xihu (West Lake) Dis.way

(1).Acceptable price with good quality

(2).Prompt delivery and good service

(3).Low noise and long life

(4).The precision is international standard

(5)We can make bearings in your drawings or samples,and if anything of interest to you,please fell free to contact to me.Thanks!

Application:

Linear bearing widely used in electronic equipment, tension tester and digital 3d coordinate measurement equipment and other precision equipment, and multi-axis machine, punch, tool grinding machine, automatic cutting machine, printer, card sorting machine installed the sliding parts such as industrial machinery.

11, Measurement instrument

HIWIN linear CZPT series:

HG series: Grinders, milling machines, lathes, drilling machines, processing machines, EDM machines, boring machines, wire cutting, precision measuring equipment, woodworking machines, handling machines, conveyor.

EG series: Industrial automation machinery, semiconductor machine, laser engraving machine, packaging machine.

MGN / MGW series: Printer, robotics, electronic equipment, semiconductor equipment.

HGH series

HGH15CA HGH20CA HGH20HA HGH 25 CA HGH30CA HGH30HA HGH35CA HGH35HA HGH45CA

HGH45HA HGH55CA HGH55HA HGH65CA HGH65HA

HGWseries

HGW15CA HGW20CA HGW20HA HGW25CA HGW25HA HGW30CA HGW30HA HGW35CA HGW35HA

HGW45CA HGW45HA HGW55CA HGW55HA

EGH series

EGH15SA EGH15CA EGH20SA EGH20SA EGH25SA EGH25CA EGH30SA EGH30CA

EGW series

EGW 15SA EGW15CA EGW20SA EGW20CA EGW25SA EGW25CA EGW30SA EGW30CA

MGN series

MGN 7C MGN 7H MGN9C MGN 9 H MGN12C MGN 12H MGN 15C MGN 15H

MGW series

MGW 7C MGW 7H MGW 9C MGW 9H MGW12C MGW 12H MGW15C MGW 15H

| Model size: | |||||||

| LM6 | LM8 | LM10 | LM12 | LM13 | LM16 | LM20 | |

| LM25 | LM30 | LM35 | LM40 | LM50 | LM60 | LM80 | LM100 |

| LM6OP | LM8OP | LM10OP | LM12OP | LM13OP | LM16OP | LM20OP | |

| LM25OP | LM30OP | LM35OP | LM40OP | LM50OP | LM60OP | LM80OP | LM100OP |

| LM6AJ | LM8AJ | LM10AJ | LM12AJ | LM13AJ | LM16AJ | LM20AJ | |

| LM25AJ | LM30AJ | LM35AJ | LM40AJ | LM50AJ | LM60AJ | LM80AJ | LM100AJ |

| LME6 | LME8 | LME10 | LME12 | LME13 | LME16 | LME20 | |

| LME25 | LME30 | LME35 | LME40 | LME50 | LME60 | LME80 | LME100 |

| LME6OP | LME8OP | LME10OP | LME12OP | LME13OP | LME16OP | LME20OP | |

| LME25OP | LME30OP | LME35OP | LME40OP | LME50OP | LME60OP | LME80OP | LME100OP |

| LME6AJ | LME8AJ | LME10AJ | LME12AJ | LME13AJ | LME16 | LME20AJ | |

| LME25AJ | LME30AJ | LME35AJ | LME40AJ | LME50AJ | LME60AJ | LME80AJ | LME100AJ |

| LMK6 | LMK8 | LMK10 | LMK12 | LMK13 | LMK16 | LMK20 | |

| LMK25 | LMK30 | LMK35 | LMK40 | LMK50 | LMK60 | LMK80 | LMK100 |

| LMF6 | LMF8 | LMF10 | LMF12 | LMF13 | LMF16 | LMF20 | |

| LMF25 | LMF30 | LMF35 | LMF40 | LMF50 | LMF60 | LMF80 | LMF100 |

| LM6L | LM8L | LM10L | LM12L | LM13L | LM16 | LM20L | |

| LM25L | LM30L | LM35L | LM40L | LM50L | LM60L | LM80L | LM100L |

| LME6L | LME8L | LME10L | LME12L | LME13L | LME16L | LME20L | |

| LME25L | LME30L | LME35L | LME40L | LME50L | LME60L | LME80L | LME100L |

| LME6LOP | LME8LOP | LME10LOP | LME12LOP | LME13LOP | LME16LOP | LME20LOP | |

| LME25LOP | LME30LOP | LME35LOP | LME40LOP | LME50LOP | LME60LOP | LME80LOP | LME100LOP |

| LME6LAJ | LME8LAJ | LME10LAJ | LME12LAJ | LME13LAJ | LME16LAJ | LME20LAJ | |

| LME25LAJ | LME30LAJ | LME35LAJ | LME40LAJ | LME50LAJ | LME60LAJ | LME80LAJ | LME100LAJ |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Gcr15, Ss, High Carbon Steel |

|---|---|

| Cetrification: | ISO 9001:2008 |

| Place of Origin: | Shandong China |

| Precision Rating: | P0 P6 P5 |

| Express: | TNT, DHL, FedEx, EMS |

| Transport Package: | as Per Client′s Requirement |

| Samples: |

US$ 0.1/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What is the typical price range for block bearings?

The price range for block bearings can vary depending on various factors such as the bearing type, size, materials, quality, and the supplier or manufacturer. Here’s a detailed explanation of the typical price range for block bearings:

1. Standard Block Bearings: Standard block bearings, commonly used in many industrial applications, are generally more affordable compared to specialized or high-performance variants. The price range for standard block bearings typically varies from a few dollars to several tens of dollars per bearing, depending on factors such as the bearing size, load capacity, and quality of construction.

2. Specialized Block Bearings: Specialized block bearings designed for specific applications or industries may have a higher price range due to their unique features, materials, or performance characteristics. For example, block bearings designed for high-speed applications, extreme temperatures, or corrosive environments may fall into a higher price range. Prices for specialized block bearings can range from tens of dollars to several hundred dollars per bearing, depending on the specific requirements and performance specifications.

3. High-Precision or Custom Block Bearings: High-precision block bearings or custom-designed bearings, which are manufactured to very tight tolerances or tailored to specific machinery requirements, can have a higher price range. These bearings often involve additional engineering, manufacturing, or quality control processes, which contribute to their higher cost. The price range for high-precision or custom block bearings can vary significantly, ranging from hundreds of dollars to several thousand dollars per bearing.

It’s important to note that the prices mentioned above are general estimates and can vary based on factors such as geographical location, market demand, quantity ordered, and supplier-specific pricing policies. Additionally, prices may also be subject to fluctuations over time due to factors such as raw material costs, manufacturing expenses, and market conditions.

When considering the price of block bearings, it’s essential to balance cost with quality and performance requirements. Opting for reputable suppliers or manufacturers known for their reliability and product quality is advisable to ensure that the block bearings meet the desired specifications and provide long-term value.

What is the lifespan of a block bearing?

The lifespan of a block bearing can vary depending on several factors, including the operating conditions, the type of bearing, the quality of the bearing and its components, and the level of maintenance and lubrication. It is challenging to provide an exact lifespan for a block bearing as it can be influenced by these variables. However, with proper installation, maintenance, and operating conditions, block bearings can have a long service life.

The manufacturer of the block bearing typically provides an estimated service life or a rating for the bearing under specific conditions. This rating is often referred to as the L10 life or the basic rating life. The L10 life represents the number of hours that 90% of a group of identical bearings are expected to operate before the onset of fatigue failure. It is important to note that the L10 life is a statistical calculation based on standardized testing and assumptions about operating conditions. Actual bearing life can vary significantly depending on the application.

Several factors can influence the lifespan of a block bearing:

- Operating Conditions: The operating conditions, including the load magnitude and direction, speed, and temperature, can significantly impact the lifespan of a block bearing. Higher loads, excessive speeds, and extreme temperatures can accelerate wear and fatigue, reducing the bearing’s lifespan.

- Maintenance and Lubrication: Regular maintenance practices, including proper lubrication, can help extend the lifespan of a block bearing. Inadequate or improper lubrication can lead to increased friction, wear, and premature failure. Regular inspection, cleaning, and re-lubrication according to the manufacturer’s recommendations are essential for optimal bearing performance and longevity.

- Quality and Design: The quality of the block bearing and its components, as well as the design and manufacturing standards, can impact its lifespan. High-quality bearings manufactured by reputable companies tend to have more consistent performance and longer lifespans compared to lower-quality alternatives.

- Application-Specific Factors: Certain applications may expose block bearings to harsh or demanding conditions, such as heavy loads, high vibrations, or corrosive environments. These factors can affect the bearing’s lifespan and may require special considerations in terms of bearing selection, materials, and maintenance.

It is important to monitor the condition of block bearings regularly and be vigilant for any signs of wear, damage, or decreased performance. By addressing issues promptly, performing routine maintenance, and following proper operating practices, it is possible to maximize the lifespan of block bearings and ensure reliable operation of the machinery.

Ultimately, the lifespan of a block bearing can vary, and it is recommended to consult the manufacturer’s guidelines and work with qualified engineers or technicians to determine the expected lifespan in specific operating conditions.

What are the common applications of block bearings?

Block bearings, also known as pillow block bearings, are widely used in various industrial applications where there is a need to support and guide rotating or oscillating shafts. These bearings offer stability, load-carrying capacity, and ease of installation. Here’s a detailed explanation of the common applications of block bearings:

- Conveyor Systems: Block bearings are extensively used in conveyor systems found in industries such as manufacturing, mining, and logistics. They provide support and smooth motion for the conveyor belts, allowing efficient material handling and transportation.

- Fans and Blowers: Block bearings are commonly employed in industrial fans, blowers, and HVAC systems. They help support the rotating shafts of the fan blades, ensuring smooth operation and minimizing vibration.

- Pumps and Compressors: Block bearings find applications in pumps and compressors, where they support the rotating shafts and help maintain the fluid or gas flow. These bearings are essential for efficient operation and reliability in various industries, including oil and gas, water treatment, and HVAC.

- Agricultural Machinery: Block bearings are used in agricultural equipment such as harvesters, tractors, and irrigation systems. They provide support for shafts and rotating components, enabling efficient operation in demanding agricultural environments.

- Food Processing Equipment: The food processing industry often utilizes block bearings in equipment like mixers, conveyors, and packaging machinery. The bearings used in these applications are typically made of food-grade materials and designed to withstand frequent cleaning and sanitization.

- Material Handling Equipment: Block bearings are employed in a wide range of material handling equipment, including forklifts, cranes, and hoists. These bearings support the shafts and mechanisms involved in lifting, moving, and positioning heavy loads.

- Mining and Construction Machinery: Block bearings are used in heavy-duty equipment found in the mining and construction industries. They provide support and smooth rotation for components like conveyor systems, crushers, and excavators, enabling efficient operation in harsh environments.

- Printing and Packaging Machinery: Block bearings are utilized in printing presses, packaging machines, and paper processing equipment. They help support the rotating shafts and rollers, ensuring precise motion and reliable operation during printing, packaging, and paper handling processes.

- Textile Machinery: Block bearings are commonly employed in textile machinery, including spinning machines, weaving looms, and dyeing equipment. They support the rotating shafts and spindles, allowing smooth and precise movement during textile production processes.

- Automotive and Transportation: Block bearings are used in various automotive applications, such as wheel hubs, suspension systems, and transmission components. They provide support and enable smooth rotation in the automotive industry, ensuring reliable performance and comfort.

These are just a few examples of the common applications of block bearings. Due to their versatility, durability, and ability to handle substantial loads, block bearings are employed in numerous industries and equipment types where rotational motion support is required.

editor by CX 2024-04-12

China OEM CZPT Trending Products Plummer Blocks Pillow Block Flange Bearing Excellent Insert Pillow Block Bearing Base Bearing for Agricultural Machinery ball bearing

Product Description

Product Description

Technical information:

| The model of pillow block bearing | |||||||

| Bearing No. | Shaft Diameter | Dim ensions/mm | kg | ||||

| in | mm | D | Bi | Be | |||

| UC201 | 12 | 47 | 31 | 17 | 0.21 | ||

| UC202 | 15 | 0.19 | |||||

| UC203 | 17 | 0.18 | |||||

| UC204 | 20 | 0.16 | |||||

| UC201-8 | 1.8504 | 1.2205 | 0.6693 | 0.2 | |||

| UC202-10 | 0.19 | ||||||

| UC203-11 | 0.18 | ||||||

| UC204-12 | 0.16 | ||||||

| UC205 | 25 | 52 | 34.1 | 17 | 0.19 | ||

| UC205-14 | 2.571 | 1.3425 | 0.669 | 0.22 | |||

| UC205-15 | 15/16 | 0.2 | |||||

| UC205-16 | 1 | 0.19 | |||||

| UC206 | 30 | 62 | 38.1 | 19 | 0.31 | ||

| UC206-17 | 1 1/16 | 2.4409 | 1.5 | 0.748 | 0.36 | ||

| UC206-18 | 1 1/8 | 0.34 | |||||

| UC206-19 | 1 3/16 | 0.32 | |||||

| UC206-20 | 1 1/4 | 0.31 | |||||

| UC207 | 35 | 72 | 42.9 | 20 | 0.46 | ||

| UC207-20 | 1 1/4 | 2.8346 | 1.689 | 0.787 | 0.52 | ||

| UC207-21 | 1 5/16 | 0.5 | |||||

| UC207-22 | 1 3/8 | 0.48 | |||||

| UC207-23 | 1 7/16 | 0.46 | |||||

| UC208 | 40 | 80 | 49.2 | 21 | 0.63 | ||

| UC208-24 | 1 1/2 | 3.1496 | 1.689 | 0.787 | 0.68 | ||

| UC208-25 | 1 9/16 | 0.64 | |||||

| UC209 | 45 | 85 | 49.2 | 22 | 0.68 | ||

| UC209-26 | 1 5/8 | 3.3465 | 1.937 | 0.866 | 0.78 | ||

| UC209-27 | 1 11/16 | 0.74 | |||||

| UC209-28 | 1 3/4 | 0.7 | |||||

| UC210 | 50 | 90 | 51.6 | 24 | 0.78 | ||

| UC210-30 | 1 7/8 | 3.5433 | 2.571 | 0.9449 | 0.85 | ||

| UC210-31 | 1 15/16 | 0.8 | |||||

| UC211 | 55 | 100 | 55.5 | 25 | 1.07 | ||

| UC211-32 | 2 | 3.637 | 2.189 | 0.9843 | 1.22 | ||

| UC211-34 | 2 1/8 | 0.1 | |||||

| UC211-35 | 2 3/16 | 1.05 | |||||

| UC212 | 60 | 110 | 65.1 | 27 | 1.52 | ||

| UC212-36 | 2 1/4 | 4.3307 | 2.563 | 1.063 | 1.65 | ||

| UC212-38 | 1 3/8 | 1.49 | |||||

| UC212-39 | 1 7/16 | 1.42 | |||||

| UC213 | 65 | 120 | 65.1 | 28 | 1.8 | ||

| UC213-40 | 2 1/2 | 4.7244 | 2.5630 | 1.1571 | 1.88 | ||

| UC214 | 70 | 125 | 74.6 | 30 | 2.06 | ||

| UC214-44 | 2 3/4 | 4.9213 | 2.9370 | 1.1811 | 2.07 | ||

| UC215 | 75 | 130 | 77.8 | 32 | 2.19 | ||

| UC215-47 | 2 15/16 | 5.1181 | 3.063 | 1.2598 | 2.21 | ||

| UC215-48 | 3 | 2.11 | |||||

| UC216 | 80 | 140 | 82.6 | 33 | 2.82 | ||

| UC216-50 | 3 1/8 | 5.5118 | 3.2520 | 1.2992 | 2.9 | ||

| UC217 | 85 | 150 | 85.7 | 35 | 3.46 | ||

| UC217-52 | 3 1/4 | 5.9055 | 3.3740 | 1.378 | 3.56 | ||

| UC218 | 90 | 160 | 96.0 | 37 | 4.56 | ||

| UC218-56 | 3 1/2 | 6.2992 | 3.7795 | 1.4567 | 4.62 | ||

Our Advantage:

1.Free Sample bearing

2.Bearing Small order accepted

3.Large bearingStocks

4.OEM bearing service

5.Professional:24 years manufacture bearing

6.Customized bearing, Customer’s bearing drawing or samples accepted

7.Competitive price bearing

MAIN PRODUCTS

Alinging ball bearings, cylindrical roller bearings, deep grove ball bearings, self-aligning roller bearings, base bearings, car hub bearings,

truck hub bearings and other products, We can customize the bearing according to the drawings or samples provided by the customer

FIELDS OF APPLICATION

Grain machinery, textile machinery, washing machinery, engineering machinery, industrial deceleration machinery,

woodworking machinery, papermaking machinery, mining machinery, coal mining machinery, lifting machinery, construction

machinery, large transportation equipment,chemical machinery, petroleum machinery, metallurgical industry, large steel mills,

cement plants,energy industry, automobiles, trucks, etc.

Packaging & Shipping

Plastic bag + single box + carton + tray;Industrial packaging + carton + pallet;

We also can According to your requirements to change.

Company Profile