Product Description

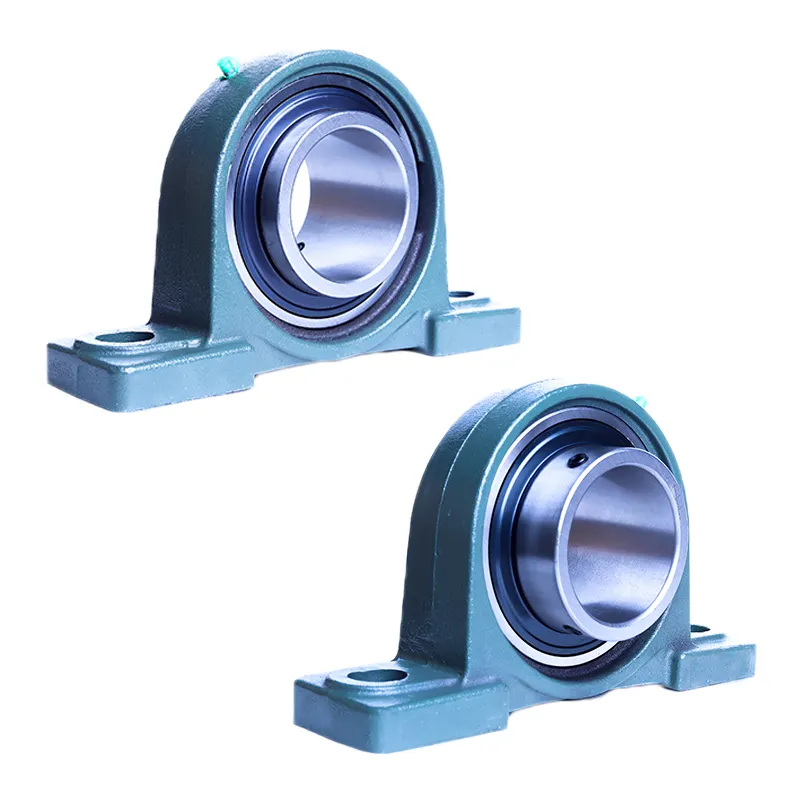

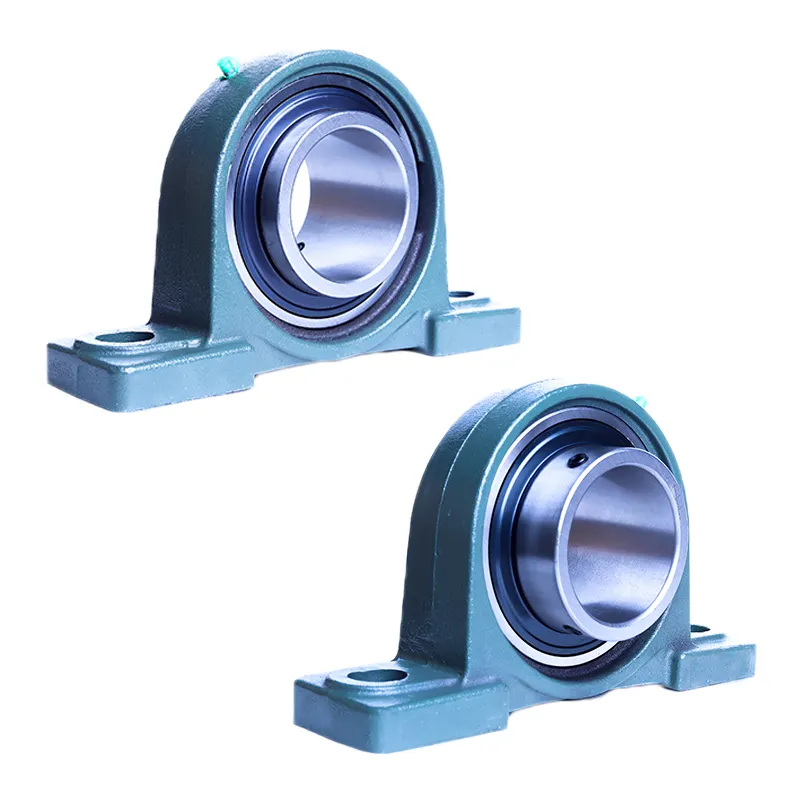

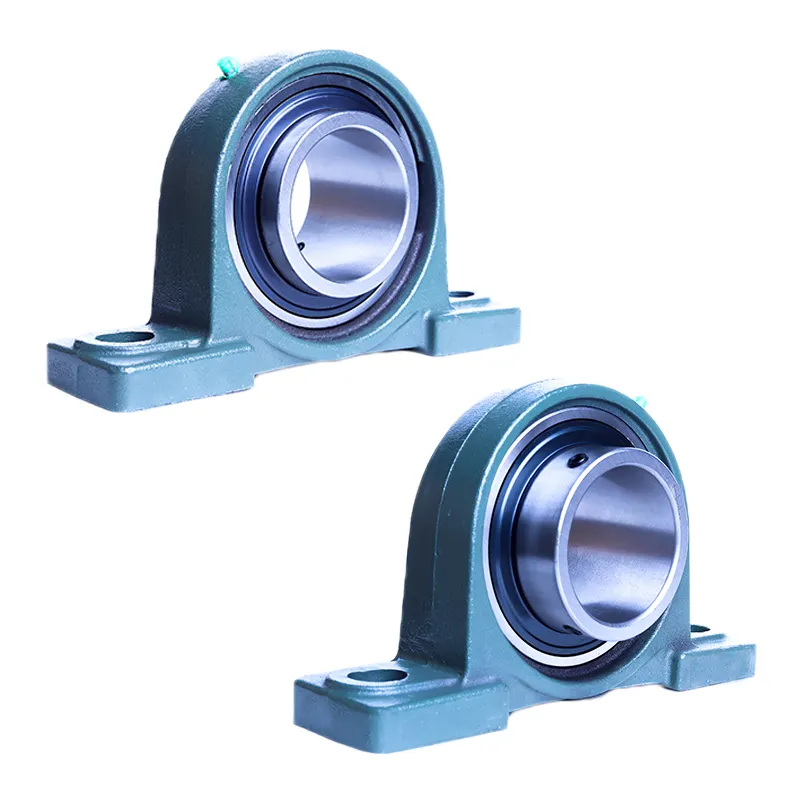

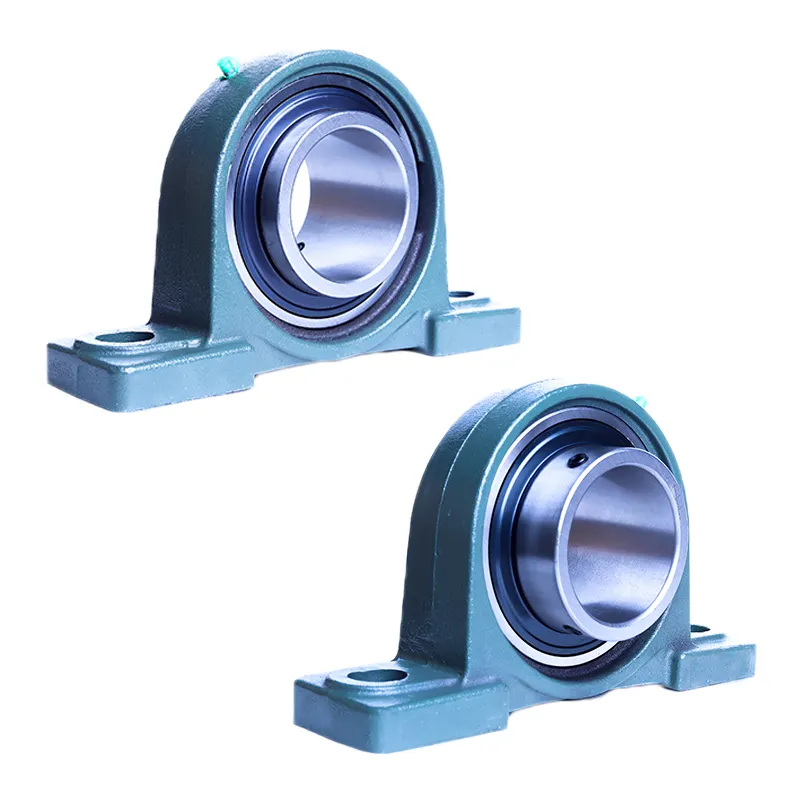

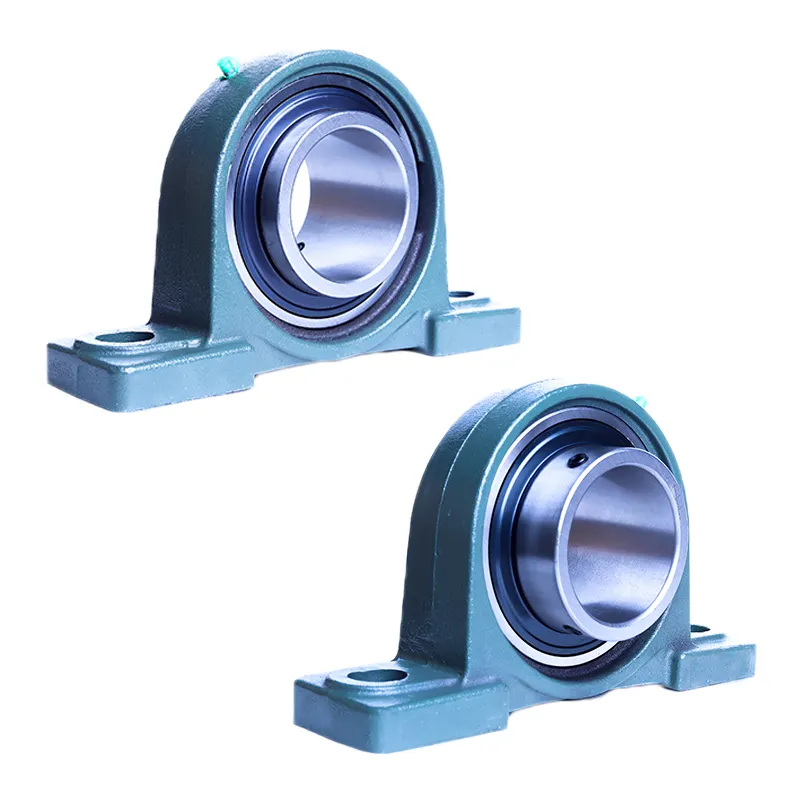

Housed external spherical bearings are a kind of bearing unit that combines rolling bearings with housings. Most of the outer spherical bearings are made into spherical outer diameter, and with a spherical bore imported bearing housing installed together, the structure of various forms, generality and interchangeability is good.

Specification

|

Bearing No |

ID (mm) |

OD (mm) |

Width (mm) |

Bearing No |

ID (mm) |

OD (mm) |

Width (mm) |

|

UCP203 |

17 |

27.4 |

129 |

UC213 |

65 |

120 |

65.1 |

|

UCP204 |

20 |

30 |

134 |

UC214 |

70 |

125 |

74.6 |

|

UCP205 |

25 |

34.1 |

142 |

UC215 |

75 |

130 |

77.8 |

|

UCP206 |

30 |

38.1 |

167 |

UC216 |

80 |

140 |

82.6 |

|

UCP207 |

35 |

42.9 |

172 |

UC217 |

85 |

150 |

85.7 |

|

UCP208 |

40 |

49.2 |

186 |

UC218 |

90 |

160 |

96 |

|

UCP209 |

45 |

49.2 |

192 |

UCHA203 |

17 |

64 |

96 |

|

UCP210 |

50 |

51.6 |

208 |

UCHA204 |

20 |

64 |

96 |

|

UCP211 |

55 |

55.6 |

233 |

UCHA205 |

25 |

78 |

103 |

|

UCP212 |

60 |

65.1 |

243 |

UCHA206 |

30 |

78 |

103 |

|

UCP213 |

65 |

65.1 |

268 |

UCHA207 |

35 |

92 |

116 |

|

UCP214 |

70 |

74.6 |

274 |

UCHA208 |

40 |

96 |

121 |

|

UCP215 |

75 |

77.8 |

300 |

UCHA209 |

45 |

108 |

136 |

|

UCP216 |

80 |

82.6 |

305 |

UC305 |

25 |

62 |

38 |

|

UCP217 |

85 |

85.7 |

330 |

UC306 |

30 |

72 |

43 |

|

UCP218 |

90 |

96 |

356 |

UC307 |

35 |

80 |

48 |

|

UCP220 |

100 |

108 |

390 |

UC308 |

40 |

90 |

52 |

|

UC203 |

17 |

40 |

27.4 |

UC309 |

45 |

100 |

57 |

|

UC204 |

20 |

47 |

31 |

UC310 |

50 |

110 |

61 |

|

UC205 |

25 |

52 |

34.1 |

UC311 |

55 |

120 |

66 |

|

UC206 |

30 |

62 |

38.1 |

UC312 |

60 |

130 |

71 |

|

UC207 |

35 |

72 |

42.9 |

UC313 |

65 |

140 |

75 |

|

UC208 |

40 |

80 |

49.2 |

UC314 |

70 |

150 |

78 |

|

UC209 |

45 |

85 |

49.2 |

UC315 |

75 |

160 |

82 |

|

UC210 |

50 |

90 |

51.6 |

UC316 |

80 |

170 |

86 |

|

UC211 |

55 |

100 |

55.6 |

UC317 |

85 |

180 |

96 |

|

UC212 |

60 |

110 |

65.1 |

UC318 |

90 |

190 |

96 |

|

Bearing No |

ID (mm) |

Thickness (mm) |

Bearing No |

ID (mm) |

Thickness (mm) |

Bearing No |

ID (mm) |

Thickness (mm) |

|

UCFL203 |

17 |

33.3 |

UCT210 |

50 |

51.6 |

UCFC218 |

90 |

78.3 |

|

UCFL204 |

20 |

33.3 |

UCT211 |

55 |

55.6 |

UCFB203 |

17 |

31 |

|

UCFL205 |

25 |

35.7 |

UCT212 |

60 |

65.1 |

UCFB204 |

20 |

31 |

|

UCFL206 |

30 |

40.2 |

UCT213 |

65 |

65.1 |

UCFB205 |

25 |

34.1 |

|

UCFL207 |

35 |

44.1 |

UCT214 |

70 |

74.6 |

UCFB206 |

30 |

38.1 |

|

UCFL208 |

40 |

51.2 |

UCT215 |

75 |

77.8 |

UCFB207 |

35 |

42.9 |

|

UCFL209 |

45 |

52.2 |

UCT216 |

80 |

82.6 |

UCFB208 |

40 |

49.2 |

|

UCFL210 |

50 |

54.6 |

UCT217 |

85 |

85.7 |

UCFB209 |

45 |

49.2 |

|

UCFL211 |

55 |

58.4 |

UCT218 |

90 |

96 |

UCFB210 |

50 |

51.6 |

|

UCFL212 |

60 |

68.7 |

UCPH203 |

17 |

31 |

UCP305 |

25 |

38 |

|

UCF203 |

17 |

33.3 |

UCPH204 |

20 |

31 |

UCP306 |

30 |

43 |

|

UCF204 |

20 |

33.3 |

UCPH205 |

25 |

34.1 |

UCP307 |

35 |

48 |

|

UCF205 |

25 |

35.7 |

UCPH206 |

30 |

38.1 |

UCP308 |

40 |

52 |

|

UCF206 |

30 |

40.2 |

UCPH207 |

35 |

42.9 |

UCP309 |

45 |

57 |

|

UCF207 |

35 |

44.4 |

UCPH208 |

40 |

49.2 |

UCP310 |

50 |

61 |

|

UCF208 |

40 |

51.2 |

UCPH209 |

45 |

49.2 |

UCP311 |

55 |

66 |

|

UCF209 |

45 |

52.2 |

UCPH210 |

50 |

51.6 |

UCP312 |

60 |

71 |

|

UCF210 |

50 |

54.6 |

UCPH211 |

55 |

55.6 |

UCP313 |

65 |

75 |

|

UCF211 |

55 |

58.4 |

UCPH212 |

60 |

65.1 |

UCP314 |

70 |

78 |

|

UCF212 |

60 |

68.7 |

UCFA203 |

17 |

32.04 |

UCP315 |

75 |

82 |

|

UCF213 |

65 |

69.7 |

UCFA204 |

20 |

32.04 |

UCP316 |

80 |

86 |

|

UCF214 |

75.4 |

70 |

UCFA205 |

25 |

35.7 |

UCP317 |

85 |

96 |

|

UCF215 |

78.5 |

75 |

UCFA206 |

30 |

40.2 |

UCP318 |

90 |

96 |

|

UCF216 |

83.3 |

80 |

UCFA207 |

35 |

44.4 |

UCF305 |

25 |

38 |

|

UCF217 |

87.6 |

85 |

UCFA208 |

40 |

51.2 |

UCF306 |

30 |

43 |

|

UCF218 |

97.3 |

90 |

UCFA209 |

45 |

52.2 |

UCF307 |

35 |

48 |

|

UCPA203 |

17 |

31 |

UCFC203 |

17 |

28.3 |

UCF308 |

40 |

52 |

|

UCPA204 |

20 |

31 |

UCFC204 |

20 |

28.3 |

UCF309 |

45 |

57 |

|

UCPA205 |

25 |

34.1 |

UCFC205 |

25 |

29.8 |

UCF310 |

50 |

61 |

|

UCPA206 |

30 |

38.1 |

UCFC206 |

30 |

32.2 |

UCF311 |

55 |

66 |

|

UCPA207 |

35 |

42.9 |

UCFC207 |

35 |

36.4 |

UCF312 |

60 |

71 |

|

UCPA208 |

40 |

49.2 |

UCFC208 |

40 |

41.2 |

UCF313 |

65 |

75 |

|

UCPA209 |

45 |

49.2 |

UCFC209 |

45 |

40.2 |

UCF314 |

70 |

78 |

|

UCPA210 |

50 |

51.6 |

UCFC210 |

50 |

42.6 |

UCF315 |

75 |

82 |

|

UCT203 |

17 |

31 |

UCFC211 |

55 |

46.4 |

UCF316 |

80 |

86 |

|

UCT204 |

20 |

31 |

UCFC212 |

60 |

56.7 |

UCF317 |

85 |

96 |

|

UCT205 |

25 |

34 |

UCFC213 |

65 |

55.7 |

UCF318 |

90 |

96 |

|

UCT206 |

30 |

38.1 |

UCFC214 |

70 |

61.4 |

|

|

|

|

UCT207 |

35 |

42.9 |

UCFC215 |

75 |

62.5 |

|

|

|

|

UCT208 |

40 |

49.2 |

UCFC216 |

80 |

67.3 |

|

|

|

|

UCT209 |

45 |

49.2 |

UCFC217 |

85 |

69.6 |

|

|

|

ZheJiang Haina Bearing Co., Ltd. is an integrated company of industry and trade. Since its establishment, it has been committed to the research and development, production, and sales of high-end 7 types of tapered roller bearings, British non-standard bearings, deep groove ball bearings, and outer spherical bearings. We can customize and adjust various types of bearings according to customer needs. The products are widely applicablein fields such as automobiles, mines, chemicals, metallurgy, reducers, engineering machinery, agricultural machinery, and electric motors.

Our company has advanced testing equipment, forming a production model of product serialization and mass production. We have a group of experienced and skilled management personnel, who have introduced advanced production equipment and measuringand testing equipment. From the purchase of bearing raw materials to the delivery of finished products, we strictly control the entire process, ensuring the quality of the products.The products have the characteristics of precision, low noise, high load-bearing capacity and long service life.

1. Your factory how to control the quality?

A: All bearing parts before the production and the production process, strict inspection by 100%, including crack detection, roundness, hardness,

roughness,and the geometry size, all bearing meet ISO international standard.

2. Can you tell me the bearing material?

A: We have chrome steel GCR15, stainless steel, ceramics and other materials.

3. How long is your delivery time?

A: If the goods are in stock, usually 5 to 10 days, if the goods are no stock for 15 to 20 days, according to the quantity to determine the time.

4. OEM and custom you can receive?

A: Yes, accept OEM, can also be customized according to samples or drawings for you.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Aligning Bearing |

|---|---|

| Separated: | Separated |

| Feature: | Vacuum, Magnetically, Low Temperature, Corrosion Resistant, High Temperature, High Speed |

| Rows Number: | Single |

| Raceway: | Deep Groove Raceway |

| Material: | Bearing Steel |

| Samples: |

US$ 10.99/Piece

1 Piece(Min.Order) | |

|---|

How do I maintain and lubricate block bearings?

Maintaining and lubricating block bearings is essential to ensure their optimal performance, prevent premature wear, and extend their service life. Here’s a detailed explanation of how to maintain and lubricate block bearings:

- Regular Inspection: Perform regular visual inspections of the block bearings to check for any signs of damage, wear, or contamination. Look for cracks, rust, excessive play, or abnormal noise. If any issues are detected, take appropriate action, such as cleaning, lubricating, or replacing the bearing.

- Cleanliness: Keep the surrounding area clean to prevent the ingress of dirt, dust, or debris into the bearing housing. Clean the housing and the surrounding components regularly using a soft cloth or brush. Avoid using harsh chemicals or excessive water, as it can damage the bearing or its lubrication.

- Lubrication: Lubrication is crucial for smooth operation and to reduce friction and wear in block bearings. Follow the manufacturer’s recommendations for the type and quantity of lubricant to be used. Some block bearings have grease fittings or seals that allow for easy lubrication. Apply the lubricant according to the manufacturer’s guidelines, ensuring that it reaches all the necessary areas, such as the bearing insert and rolling elements.

- Lubrication Frequency: The frequency of lubrication depends on various factors, such as the bearing type, operating conditions, and manufacturer’s recommendations. In general, block bearings should be lubricated regularly, especially in high-speed or high-load applications. However, excessive lubrication can cause overheating or leakage, so it’s important to follow the recommended lubrication intervals.

- Monitor Temperature: During operation, monitor the temperature of the block bearings regularly. Excessive heat can indicate insufficient lubrication or other issues. If the temperature rises significantly or exceeds the manufacturer’s recommendations, investigate and address the root cause to prevent bearing damage.

- Sealing: Check the sealing arrangements of the block bearings to ensure they are intact and functioning properly. Seals help protect the bearing from contaminants and retain the lubricant. If seals are damaged or worn, replace them promptly to maintain the integrity of the bearing’s lubrication system.

- Training and Expertise: If you are not familiar with block bearing maintenance, consider seeking training or guidance from the manufacturer or a qualified professional. They can provide you with specific instructions and best practices for maintaining and lubricating block bearings in your particular application.

Following these maintenance and lubrication practices can help ensure the proper functioning and longevity of block bearings. Remember to consult the manufacturer’s documentation and guidelines specific to your block bearing model for detailed instructions and recommendations.

What are the signs of a failing block bearing?

A failing block bearing can exhibit various signs and symptoms that indicate potential issues. Recognizing these signs is crucial for timely maintenance or replacement to prevent further damage to the machinery. Here’s a detailed explanation of the common signs of a failing block bearing:

- Abnormal Noise: Unusual noises coming from the machinery, such as grinding, squealing, or rumbling sounds, can be indicative of a failing block bearing. These noises may occur during operation or when the machinery is under load.

- Vibration: Excessive vibration in the machinery can be a sign of a failing block bearing. If you notice increased levels of vibration during operation, especially in conjunction with other symptoms, it may indicate bearing wear or misalignment.

- Increased Temperature: A failing block bearing can generate excessive heat due to increased friction. If you observe abnormally high temperatures in the bearing housing or around the bearing area, it could be a sign of impending bearing failure.

- Irregular Operation: Changes in the smoothness or regularity of the machinery’s operation, such as intermittent or irregular motion, can be a result of a failing block bearing. This can manifest as jerky movements, sticking, or hesitation during operation.

- Loss of Lubrication: Insufficient or loss of lubrication can lead to bearing failure. If you notice signs of inadequate lubrication, such as dry or discolored lubricant, or if the bearing is running dry, it can accelerate wear and contribute to bearing failure.

- Visible Damage: Physical damage to the block bearing or its components, such as cracks, dents, or corrosion, can indicate a failing bearing. Additionally, if you observe excessive play or movement in the bearing, it may be a sign of wear or damage.

- Inconsistent Performance: A failing block bearing can result in inconsistent or reduced performance of the machinery. This may include decreased speed, reduced load-carrying capacity, or compromised precision in applications that require high accuracy.

- Increased Friction: If you notice an increase in friction or resistance when rotating or moving the machinery by hand, it may suggest a failing block bearing. Difficulty in turning the shaft or a feeling of roughness can indicate excessive wear or damage in the bearing.

It’s important to note that these signs can also be indicative of other issues in the machinery. Therefore, a thorough inspection by a qualified technician or engineer is recommended to accurately diagnose the problem. Regular maintenance, including visual inspections and monitoring of operating conditions, can help identify early signs of bearing failure and allow for timely intervention.

If you observe any of the mentioned signs, it’s crucial to address the issue promptly to prevent further damage to the machinery. Timely maintenance or replacement of failing block bearings can help ensure the continued reliable operation of the machinery and prevent costly breakdowns.

What are the standard dimensions for block bearings?

The dimensions of block bearings, also known as pillow block bearings, can vary depending on the specific design and manufacturer. However, there are standard dimensions that are commonly used in the industry. Here’s a detailed explanation of the standard dimensions for block bearings:

Block bearings consist of a bearing insert (also called an inner ring) and a housing (also called an outer ring or pillow block). The housing is typically a solid or split housing with mounting holes for attachment to a support structure. The bearing insert is designed to fit inside the housing and supports the rotating shaft. The dimensions of block bearings are typically specified using the following parameters:

- Shaft Diameter (d): This refers to the diameter of the shaft that will be inserted into the bearing. The standard shaft diameters for block bearings range from a few millimeters up to several inches, depending on the application requirements. Common shaft diameter sizes include 1/2″, 5/8″, 3/4″, 1″, 1-1/4″, 1-1/2″, and 2″.

- Housing Length (L): The housing length refers to the distance between the mounting surfaces of the housing. It determines the overall length of the block bearing assembly. The housing length can vary depending on the bearing size and design, but common lengths range from around 2 inches to several inches or more.

- Housing Width (B): The housing width refers to the width of the housing, perpendicular to the shaft. It determines the overall width of the block bearing assembly. The housing width can vary depending on the bearing size and design, but common widths range from around 1 inch to several inches or more.

- Mounting Hole Spacing (Bolt Hole Centers): Block bearings typically have multiple mounting holes for attachment to the support structure. The mounting hole spacing refers to the distance between the centers of these mounting holes. The standard mounting hole spacing is often specified using a bolt hole center-to-center distance, such as 2-bolt, 3-bolt, or 4-bolt configurations. The specific dimensions can vary depending on the bearing size and design.

- Bearing Insert Width (Bearing Width): The bearing insert width refers to the width of the bearing insert itself. It determines the amount of support and contact area for the rotating shaft. The bearing insert width can vary depending on the bearing size and design, but common widths range from around 0.5 inch to several inches or more.

It’s important to note that these are general standard dimensions, and variations may exist depending on the specific manufacturer and bearing type. Additionally, some block bearings may have additional features or variations in dimensions to cater to specific applications or industry requirements.

When selecting a block bearing, it’s crucial to consider the specific dimensions required for your application, including the shaft diameter, housing length and width, and mounting hole spacing. Consulting the manufacturer’s specifications and guidelines is recommended to ensure the correct dimensions are chosen for your specific needs.

editor by CX 2024-05-09

China OEM High Quality Insert Pillow Block Ball Bearing UC316 Machine Used Block Bearing bearing engineering

Product Description

ABOUT US

Founded in 2000, it has become a professional bearing manufacturer with advanced bearing production technology and the most advanced CNC equipment in China. The whole production process from raw materials to finished products, from design to manufacturing, is produced in accordance with national standards. The main production: spherical roller bearings, insert bearings, housings, deep groove ball bearings, adapter sleeves, and cylindrical roller bearings, with an annual output of more than 5 million sets, with an output value of more than 40 million yuan. The quality of the finished product meets the national inspection standards and has stable reliability.

Our Bearing Advantage:

1. Free Sample bearing;

2.ISO Standard;

3. Bearing Small order accepted;

4. In Stock bearing;

5. OEM/ODM bearing service;

6. Professional: more than 20 years of manufacture bearing;

7. Customized bearing, Customer’s bearing drawing or samples accepted;

8. Competitive price bearing: factory outlet.

KOYO CZPT CZPT UC Series Insert Roller Ball Bearings for Spare Parts

Product Description

Good quality ball bearings UC insert bearing

1.Prodcut name : UC ball bearing

2.Broe diameter:20mm-200mm

3.Precision level:P5,P6,P0

4.Sealing form:OPEN,Z,ZZ,RS,2RS,2RZ.N

5.Package:Wooden packing or pallet packing or according to the customer’s requirements.

6.OEM is available

Parameters of Bearing

More details of UC211-34 UC, UG, UCP, UCFL, UCF, SA, SB, SN, UT Pillow Block Bearing/Insert Bearing

| BearingUint No. | Shaft Dia d | Dimensinons(mm) | Bolt Used | Bearing No. | Housing No. | Housing Wt (kg) |

|||||||||||||

| h | a | e | b | S2 | S1 | g | w | t | Z | Bi | n | (mm) | (in) | ||||||

| (in) | (mm) | ||||||||||||||||||

| UCP201-8 | 1/2 | 30.2 | 127 | 95 | 38 | 19 | 13 | 14 | 62 | 2 | 51 | 31 | 12.7 | M10 | 3/8 | UC201-8 | P203 | 0.33 | |

| UCP202-9 | 9/16 | UC202-9 | |||||||||||||||||

| UCP202-10 | 5/8 | UC202-10 | |||||||||||||||||

| UCP203-11 | 11/16 | UC203-11 | |||||||||||||||||

| UCP201 | 12 | UC201 | |||||||||||||||||

| UCP202 | 15 | UC202 | |||||||||||||||||

| UCP203 | 17 | UC203 | |||||||||||||||||

| UCP204-12 | 3/4 | 33.3 | 127 | 95 | 38 | 19 | 13 | 14 | 65 | 2 | 51 | 31 | 12.7 | M10 | 3/8 | UC204-12 | P204 | 0.46 | |

| UCP204 | 20 | UC204 | |||||||||||||||||

| UCP205-13 | 13/16 | 25 | 36.5 | 140 | 105 | 38 | 19 | 13 | 15 | 71 | 2 | 57 | 34.1 | 14.3 | M10 | 3/8 | UC205-13 | P205 | 0.60 |

| UCP205-14 | 7/8 | UC205-14 | |||||||||||||||||

| UCP205-15 | 15/16 | UC205-15 | |||||||||||||||||

| UCP205-16 | 1 | UC205-16 | |||||||||||||||||

| UCP205 | UC205 | ||||||||||||||||||

| UCP206-17 | 1-1/16 | 30 | 42.9 | 165 | 121 | 48 | 21 | 17 | 17 | 83 | 2 | 62 | 38.1 | 15.9 | M14 | 1/2 | UC206-17 | P206 | 0.97 |

| UCP206-18 | 1-1/8 | UC206-18 | |||||||||||||||||

| UCP206-19 | 1-3/16 | UC206-19 | |||||||||||||||||

| UCP206-20 | 1-1/4 | UC206-20 | |||||||||||||||||

| UCP206 | UC206 | ||||||||||||||||||

| UCP207-20 | 1-1/4 | 35 | 47.6 | 167 | 127 | 48 | 21 | 17 | 18 | 93 | 3 | 72 | 42.9 | 17.5 | M14 | 1/2 | UC207-20 | P207 | 1.00 |

| UCP207-21 | 1-5/16 | UC207-21 | |||||||||||||||||

| UCP207-22 | 1-3/8 | UC207-22 | |||||||||||||||||

| UCP207-23 | 1-7/16 | UC207-23 | |||||||||||||||||

| UCP207 | UC207 | ||||||||||||||||||

| UCP208-24 | 1-1/2 | 40 | 49.2 | 184 | 137 | 54 | 21 | 17 | 18 | 98 | 3 | 82 | 49.2 | 19.0 | M14 | 1/2 | UC208-24 | P208 | 1.30 |

| UCP208-25 | 1-9/16 | UC208-25 | |||||||||||||||||

| UCP208 | UC208 | ||||||||||||||||||

| UCP209-26 | 1-5/8 | 45 | 54 | 190 | 146 | 54 | 21 | 17 | 20 | 106 | 3 | 82 | 49.2 | 19.0 | M14 | 1/2 | UC209-26 | P209 | 1.40 |

| UCP209-27 | 1-11/16 | UC209-27 | |||||||||||||||||

| UCP209-28 | 1-3/4 | UC209-28 | |||||||||||||||||

| UCP209 | UC209 | ||||||||||||||||||

| UCP210-29 | 1-13/16 | 50 | 57.2 | 206 | 159 | 60 | 25 | 20 | 21 | 114 | 3 | 87 | 51.6 | 19.0 | M16 | 5/8 | UC210-29 | P210 | 1.83 |

| UCP210-30 | 1-7/8 | UC210-30 | |||||||||||||||||

| UCP210-31 | 1-15/16 | UC210-31 | |||||||||||||||||

| UCP210-32 | 2 | UC210-32 | |||||||||||||||||

| UCP210 | UC210 | ||||||||||||||||||

| UCP211-32 | 2 | 55 | 63.5 | 219 | 171 | 60 | 25 | 20 | 23 | 126 | 4 | 92 | 55.6 | 22.2 | M16 | 5/8 | UC211-32 | P211 | 2.4 |

| UCP211-33 | 2-1/16 | UC211-33 | |||||||||||||||||

| UCP211-34 | 2-1/8 | UC211-34 | |||||||||||||||||

| UCP211-35 | 2-3/16 | UC211-35 | |||||||||||||||||

| UCP211 | UC211 | ||||||||||||||||||

| UCP212-36 | 2-1/4 | 60 | 69.8 | 241 | 184 | 70 | 25 | 20 | 25 | 138 | 4 | 102 | 65.1 | 25.4 | M16 | 5/8 | UC212-36 | P212 | 2.8 |

| UCP212-37 | 2-5/16 | UC212-37 | |||||||||||||||||

| UCP212-38 | 2-3/8 | UC212-38 | |||||||||||||||||

| UCP212-39 | 2-7/16 | UC212-39 | |||||||||||||||||

| UCP212 | UC212 | ||||||||||||||||||

| UCP213-40 | 2-1/2 | 65 | 76.2 | 265 | 203 | 70 | 29 | 25 | 27 | 151 | 4 | 107 | 65.1 | 25.4 | M20 | 3/4 | UC213-40 | P213 | 3.5 |

| UCP213-41 | 2-9/16 | UC213-41 | |||||||||||||||||

| UCP213 | UC213 | ||||||||||||||||||

| UCP214-42 | 2-5/8 | 70 | 79.4 | 266 | 210 | 72 | 31 | 25 | 27 | 157 | 74.6 | 30.2 | M20 | 3/4 | UC214-42 | P214 | 4.45 | ||

| UCP214-43 | 2-11/16 | UC214-43 | |||||||||||||||||

| UCP214-44 | 2-3/4 | UC214-44 | |||||||||||||||||

| UCP214 | UC214 | ||||||||||||||||||

| UCP215-45 | 2-13/16 | 75 | 82.6 | 275 | 217 | 74 | 31 | 25 | 28 | 163 | 77.8 | 33.3 | M20 | 3/4 | UC215-45 | P215 | 4.9 | ||

| UCP215-46 | 2-7/8 | UC215-46 | |||||||||||||||||

| UCP215-47 | 2-15/16 | UC215-47 | |||||||||||||||||

| UCP215-48 | 3 | UC215-48 | |||||||||||||||||

| UCP215 | UC215 | ||||||||||||||||||

| UCP216-50 | 3-1/8 | 80 | 88.9 | 292 | 232 | 78 | 31 | 25 | 30 | 175 | 82.6 | 33.3 | M20 | 3/4 | UC216-50 | P216 | 5.8 | ||

| UCP216 | UC216 | ||||||||||||||||||

| UCP217-52 | 3-1/4 | 85 | 95.2 | 310 | 247 | 83 | 31 | 25 | 32 | 187 | 85.7 | 34.1 | M20 | 3/4 | UC217-52 | P217 | 6.9 | ||

| UCP217 | UC217 | ||||||||||||||||||

| UCP218-56 | 3-1/2 | 90 | 101.6 | 327 | 262 | 88 | 33 | 27 | 33 | 200 | 96.0 | 39.7 | M22 | 7/8 | UC218-56 | P218 | 8.10 | ||

| Bearing Unit NO. |

Shaft Dia d | Dimensions(mm) | Bolt Used | Bearing No. | Housing No. | Housing Wt (kg) |

|||||||||||

| (in) | (mm) | h | a | e | b | s2 | s1 | g | w | Bi | n | (in) | (mm) | ||||

| UCP305-14 UCP305-15 UCP305-16 UCP305 |

7/8 15/16 1 |

25 | 45 | 175 | 132 | 45 | 20 | 17 | 15 | 85 | 38 | 15 | 1/2 | M14 | UC305-14 UC305-15 UC305-16 UC305 |

P305 | 0.90 |

| UCP306-18 UCP306-19 UCP306 |

1-1/8 1-3/16 |

30 | 50 | 180 | 140 | 50 | 20 | 17 | 18 | 95 | 43 | 17 | 1/2 | M14 | UC306-18 UC306-19 UC306 |

P306 | 1.10 |

| UCP307-20 UCP307-21 UCP307-22 UCP307-23 UCP307 |

1-1/4 1-5/16 1-3/8 1-7/16 |

35 | 56 | 210 | 160 | 56 | 25 | 17 | 20 | 106 | 48 | 19 | 1/2 | M14 | UC307-20 UC307-21 UC307-22 UC307-23 UC307 |

P307 | 1.95 |

| UCP308-24 UCP308-25 UCP308 |

1-1/2 1-9/16 |

40 | 60 | 220 | 170 | 60 | 27 | 17 | 22 | 116 | 52 | 19 | 1/2 | M14 | UC308-24 UC308-25 UC308 |

P308 | 2.20 |

| UCP309-26 UCP309-27 UCP309-28 UCP309 |

1-5/8 1-11/16 1-3/4 |

45 | 67 | 245 | 190 | 67 | 30 | 20 | 24 | 129 | 57 | 22 | 5/8 | M16 | UC309-26 UC309-27 UC309-28 UC309 |

P309 | 3.30 |

| UCP310-30 UCP310-31 UCP310 |

1-7/8 1-15/16 |

50 | 75 | 275 | 212 | 75 | 35 | 20 | 27 | 143 | 61 | 22 | 5/8 | M16 | UC310-30 UC310-31 UC310 |

P310 | 4.80 |

| UCP311-32 UCP311-34 UCP311-35 UCP311 |

2 2-3/8 2-3/16 |

55 | 80 | 310 | 236 | 80 | 38 | 20 | 30 | 154 | 66 | 25 | 5/8 | M16 | UC311-32 UC311-34 UC311-35 UC311 |

P311 | 5.30 |

| UCP312-36 UCP312-38 UCP312-39 UCP312 |

2-1/4 2-3/8 2-7/16 |

60 | 85 | 330 | 250 | 85 | 38 | 25 | 32 | 165 | 71 | 26 | 3/4 | M20 | UC312-36 UC312-38 UC312-39 UC312 |

P312 | 6.30 |

| UCP313-40 UCP313 |

2-1/2 | 65 | 90 | 340 | 260 | 90 | 38 | 25 | 33 | 176 | 75 | 30 | 3/4 | M20 | UC313-40 UC313 |

P313 | 8.00 |

| UCP314-44 UCP314 |

2-3/4 | 70 | 95 | 360 | 280 | 90 | 40 | 27 | 35 | 187 | 78 | 33 | 7/8 | M22 | UC314-44 UC314 |

P314 | 8.30 |

| UCP315-48 UCP315 |

3 | 75 | 100 | 380 | 290 | 100 | 40 | 27 | 35 | 198 | 82 | 32 | 7/8 | M22 | UC315-48 UC315 |

P315 | 9.50 |

| UCP316-50 UCP316 |

3-1/8 | 80 | 106 | 400 | 300 | 110 | 40 | 27 | 40 | 210 | 86 | 34 | 7/8 | M22 | UC316-50 UC315 |

P316 | 12.50 |

| UCP317-52 UCP317 |

3-1/4 | 85 | 112 | 420 | 320 | 110 | 45 | 33 | 40 | 220 | 96 | 40 | 1 | M27 | UC317-52 UC317 |

P317 | 14.50 |

| UCP318-56 UCP318 |

3-1/2 | 90 | 118 | 430 | 330 | 110 | 45 | 33 | 45 | 235 | 96 | 40 | 1 | M27 | UC318-56 UC318 |

P318 | 20.40 |

| UCP319-60 UCP319 |

3-3/4 | 95 | 125 | 470 | 360 | 120 | 50 | 36 | 45 | 250 | 103 | 41 | 1-1/8 | M30 | UC319-60 UC319 |

P319 | 22.30 |

| UCP320-64 UCP320 |

4 | 100 | 140 | 490 | 380 | 120 | 50 | 36 | 50 | 275 | 108 | 42 | 1-1/8 | M30 | UC320-64 UC320 |

P320 | 25.00 |

| UCP321 | 105 | 140 | 490 | 380 | 120 | 50 | 36 | 50 | 280 | 112 | 44 | 1-1/8 | M30 | UC321 | P321 | 24.00 | |

| UCP322 | 110 | 150 | 520 | 400 | 140 | 55 | 40 | 55 | 300 | 117 | 46 | M33 | UC322 | P322 | 27.50 | ||

| UCP324 | 120 | 160 | 570 | 450 | 140 | 55 | 40 | 65 | 320 | 126 | 51 | M33 | UC324 | P324 | 32.30 | ||

| UCP326 | 130 | 180 | 600 | 480 | 140 | 55 | 40 | 75 | 355 | 135 | 54 | M33 | UC326 | P326 | 41.00 | ||

| UCP328 | 140 | 200 | 620 | 500 | 140 | 55 | 40 | 75 | 390 | 145 | 59 | M33 | UC328 | P328 | 50.00 | ||

| BearingUint No. | Shaft Dia d | Dimensinons(mm) | Bolt Used | Bearing No. | Housing No. | Housing Wt (kg) |

|||||||||||

| h | a | e | b | S2 | S1 | g | w | Bi | n | (mm) | (in) | ||||||

| (in) | (mm) | ||||||||||||||||

| UCPE201-8 | 1/2 | 30.2 | 124 | 95 | 31 | 15 | 11 | 14 | 57.1 | 26 | 10 | M8 | 5/16 | UCW201-8 | PE203 | 0.45 | |

| UCPE202-9 | 9/16 | UCW202-9 | |||||||||||||||

| UCPE202-10 | 5/8 | UCW202-10 | |||||||||||||||

| UCPE203-11 | 11/16 | UCW203-11 | |||||||||||||||

| UCPE201 | 12 | UCW201 | |||||||||||||||

| UCPE202 | 15 | UCW202 | |||||||||||||||

| UCPE203 | 17 | UCW203 | |||||||||||||||

| UCPE204-12 | 3/4 | 33.3 | 127 | 95 | 38 | 16 | 13 | 15 | 65 | 31 | 12.7 | M10 | 3/8 | UC204-12 | PE204 | 0.65 | |

| UCPE204 | 20 | UC204 | |||||||||||||||

| UCPE205-13 | 13/16 | 25 | 36.6 | 140 | 105 | 38 | 16 | 13 | 16 | 70 | 34 | 14.3 | M10 | 3/8 | UC205-13 | PE205 | 0.75 |

| UCPE205-14 | 7/8 | UC205-14 | |||||||||||||||

| UCPE205-15 | 15/16 | UC205-15 | |||||||||||||||

| UCPE205-16 | 1 | UC205-16 | |||||||||||||||

| UCPE205 | UC205 | ||||||||||||||||

| UCPE206-17 | 1-1/16 | 30 | 42.9 | 165 | 121 | 48 | 21 | 17 | 18 | 83 | 38.1 | 15.9 | M14 | 1/2 | UC206-17 | PE206 | 1.15 |

| UCPE206-18 | 1-1/8 | UC206-18 | |||||||||||||||

| UCPE206-19 | 1-3/16 | UC206-19 | |||||||||||||||

| UCPE206-20 | 1-1/4 | UC206-20 | |||||||||||||||

| UCPE206 | UC206 | ||||||||||||||||

| UCPE207-20 | 1-1/4 | 35 | 47.6 | 167 | 127 | 48 | 21 | 17 | 19 | 94 | 42.9 | 17.5 | M14 | 1/2 | UC207-20 | PE207 | 1.30 |

| UCPE207-21 | 1-5/16 | UC207-21 | |||||||||||||||

| UCPE207-22 | 1-3/8 | UC207-22 | |||||||||||||||

| UCPE207-23 | 1-7/16 | UC207-23 | |||||||||||||||

| UCPE207 | UC207 | ||||||||||||||||

| UCPE208-24 | 1-1/2 | 40 | 49.2 | 137 | 54 | 25 | 17 | 19 | 100 | 49.2 | 19.0 | M14 | 1/2 | UC208-24 | PE208 | 1.50 | |

| UCPE208-25 | 1-9/16 | UC208-25 | |||||||||||||||

| UCPE208 | UC208 | ||||||||||||||||

| UCPE209-26 | 1-5/8 | 45 | 54 | 190 | 146 | 54 | 25 | 17 | 20 | 108 | 49.2 | 19.0 | M14 | 1/2 | UC209-26 | 1.75 | |

| UCPE209-27 | 1-11/16 | UC209-27 | |||||||||||||||

| UCPE209-28 | 1-3/4 | UC209-28 | |||||||||||||||

| UCPE209 | UC209 | ||||||||||||||||

| UCPE210-29 | 1-13/16 | 50 | 57.2 | 206 | 159 | 60 | 25 | 20 | 22 | 114 | 51.6 | 19.0 | M16 | 5/8 | UC210-29 | PE210 | 2.35 |

| UCPE210-30 | 1-7/8 | UC210-30 | |||||||||||||||

| UCPE210-31 | 1-15/16 | UC210-31 | |||||||||||||||

| UCPE210-32 | 2 | UC210-32 | |||||||||||||||

| UCPE210 | UC210 | ||||||||||||||||

| UCPE211-32 | 2 | 55 | 63.5 | 219 | 171 | 60 | 25 | 20 | 22 | 126 | 55.6 | 22.2 | M16 | 5/8 | UC211-32 | PE211 | 2.60 |

| UCPE211-33 | 2-1/16 | UC211-33 | |||||||||||||||

| UCPE211-34 | 2-1/8 | UC211-34 | |||||||||||||||

| UCPE211-35 | 2-3/16 | UC211-35 | |||||||||||||||

| UCPE211 | UC211 | ||||||||||||||||

| UCPE212-36 | 2-1/4 | 60 | 69.8 | 241 | 184 | 70 | 25 | 20 | 25 | 138 | 65.1 | 25.4 | M16 | 5/8 | UC212-36 | PE212 | 4.00 |

| UCPE212-37 | 2-5/16 | UC212-37 | |||||||||||||||

| UCPE212-38 | 2-3/8 | UC212-38 | |||||||||||||||

| UCPE212-39 | 2-7/16 | UC212-39 | |||||||||||||||

| UCPE212 | UC212 | ||||||||||||||||

| UCPE213-40 | 2-1/2 | 65 | 76.2 | 265 | 203 | 70 | 29 | 25 | 27 | 65.1 | 25.4 | M20 | 3/4 | UC213-40 | PE213 | 4.77 | |

| UCPE213-41 | 2-9/16 | UC213-41 | |||||||||||||||

| UCPE213 | UC213 | ||||||||||||||||

| UCPE214-42 | 2-5/8 | 70 | 79.4 | 266 | 210 | 72 | 31 | 25 | 27 | 156 | 74.6 | 30.2 | M20 | 3/4 | UC214-42 | PE214 | 5.30 |

| UCPE214-43 | 2-11/16 | UC214-43 | |||||||||||||||

| UCPE214-44 | 2-3/4 | UC214-44 | |||||||||||||||

| UCPE214 | UC214 | ||||||||||||||||

| UCPE215-45 | 2-13/16 | 75 | 82.6 | 275 | 217 | 74 | 31 | 25 | 28 | 163 | 77.8 | 33.3 | M20 | 3/4 | UC215-45 | PE215 | 6.00 |

| UCPE215-46 | 2-7/8 | UC215-46 | |||||||||||||||

| UCPE215-47 | 2-15/16 | UC215-47 | |||||||||||||||

| UCPE215-48 | 3 | UC215-48 | |||||||||||||||

| UCPE215 | UC215 | ||||||||||||||||

Our packing:

* Industrial pakage+outer carton+pallets

* sigle box+outer carton+pallets

* Tube package+middle box+outer carton+pallets

* According to your requirments

Company Profile

ABOUT US

BEARING MANUFACTURE

1. 20+ years of experience in manufacturing bearing;

2.Annual output value of more than 40 million yuan;

3.Passed the ISO9001 international quality certification system;

4.160 sets imported production equipments;

5.Professional sales team.

We have been engaged in foreign trade for more than 6 years and are well-known enterprises in ZheJiang Province. The fixed assets of the machine are more than 2 million US dollars, and the annual foreign trade sales volume exceeds 2 million US dollars.

We have extensive cooperation with countries in Asia, Europe, and the Americas. Including Russia, Ukraine, elaruBelaruss, Kazakhstan, Uzbekistan, Tajikistan, Spain, Mexico,India, Pakistan, Turkey, Vietnam and other industrial areas.

Export to many countries

HangZhou Jinrui Bearing Co., Ltd. not only has customers in many industries in China, but the company’s products are also exported to India, Southeast Asia, the Middle East, Europe and the United States and other countries. It has independent export rights and more than 10 years of foreign trade export experience.

FAQ

SAMPLES

1.Samples quantity: 1-10 pcs are available.

2.Free samples: It depends on the model NO., material and quantity. Some of the bearings samples need client to pay

samples charge and shipping cost.

3.It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1.MOQ: 10 pcs mix different standard bearings.

2.MOQ: 3000 pcs customized your brand bearings.

OEM POLICY

1.We can printing your brand (logo,artwork)on the shield or laser engraving your brand on the shield.

2.We can custom your packaging according to your design

3.All copyright own by clients and we promised don’t disclose any info.

SUPORT

Please visit our bearings website, we strongly encourge that you can communicate with us through email,thanks!

We have all kinds of bearings, just tell me your item number and quantity,best price will be offered to you soon

The material of the bearings, precision rating, seals type,OEM service,etc, all of them we can make according to your requirement.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | Small and Medium-Sized (60-115mm) |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Separated |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What is the typical price range for block bearings?

The price range for block bearings can vary depending on various factors such as the bearing type, size, materials, quality, and the supplier or manufacturer. Here’s a detailed explanation of the typical price range for block bearings:

1. Standard Block Bearings: Standard block bearings, commonly used in many industrial applications, are generally more affordable compared to specialized or high-performance variants. The price range for standard block bearings typically varies from a few dollars to several tens of dollars per bearing, depending on factors such as the bearing size, load capacity, and quality of construction.

2. Specialized Block Bearings: Specialized block bearings designed for specific applications or industries may have a higher price range due to their unique features, materials, or performance characteristics. For example, block bearings designed for high-speed applications, extreme temperatures, or corrosive environments may fall into a higher price range. Prices for specialized block bearings can range from tens of dollars to several hundred dollars per bearing, depending on the specific requirements and performance specifications.

3. High-Precision or Custom Block Bearings: High-precision block bearings or custom-designed bearings, which are manufactured to very tight tolerances or tailored to specific machinery requirements, can have a higher price range. These bearings often involve additional engineering, manufacturing, or quality control processes, which contribute to their higher cost. The price range for high-precision or custom block bearings can vary significantly, ranging from hundreds of dollars to several thousand dollars per bearing.

It’s important to note that the prices mentioned above are general estimates and can vary based on factors such as geographical location, market demand, quantity ordered, and supplier-specific pricing policies. Additionally, prices may also be subject to fluctuations over time due to factors such as raw material costs, manufacturing expenses, and market conditions.

When considering the price of block bearings, it’s essential to balance cost with quality and performance requirements. Opting for reputable suppliers or manufacturers known for their reliability and product quality is advisable to ensure that the block bearings meet the desired specifications and provide long-term value.

Are there different grades or types of block bearings?

Yes, there are different grades and types of block bearings available to suit various applications and operating conditions. Block bearings, also known as pillow block bearings or plummer block bearings, come in a range of designs and configurations to accommodate different shaft sizes, loads, speeds, and environmental factors. Here are some common grades and types of block bearings:

1. Standard Duty Block Bearings: Standard duty block bearings are commonly used in general applications with moderate loads and speeds. They are designed to provide reliable support for rotating shafts in a wide range of industries and machinery.

2. Heavy Duty Block Bearings: Heavy duty block bearings are specifically designed to handle higher loads and more demanding operating conditions compared to standard duty bearings. They are suitable for applications that involve heavy loads, shock loads, or high-speed rotation.

3. High-Temperature Block Bearings: High-temperature block bearings are designed to withstand elevated temperatures without compromising their performance or longevity. They are commonly used in applications where the operating temperatures exceed the capabilities of standard bearings.

4. Corrosion-Resistant Block Bearings: Corrosion-resistant block bearings are made from materials or coatings that provide protection against corrosive environments. These bearings are used in industries such as food processing, chemical processing, or marine applications where exposure to moisture, chemicals, or other corrosive agents is a concern.

5. Split Block Bearings: Split block bearings feature a housing that can be split into two or more pieces, allowing for easier installation and maintenance. They are often used in applications where it is difficult to access or remove the bearing without disassembling other components.

6. Self-Aligning Block Bearings: Self-aligning block bearings have a spherical outer diameter that allows for self-alignment, compensating for minor shaft misalignments. These bearings are suitable for applications where shaft deflection or misalignment is expected.

7. Flange Block Bearings: Flange block bearings have a flanged housing that provides additional support and stability. They are commonly used in applications where the bearing needs to be bolted to a structure or where space constraints limit the use of traditional block bearings.

8. Specialty Block Bearings: There are also specialty block bearings designed for specific applications or industries. For example, there are block bearings optimized for high-speed applications, extreme temperatures, vacuum environments, or specific industries like mining or agriculture.

It’s important to consult the manufacturer’s specifications and guidelines to select the appropriate grade and type of block bearing for a specific application. Factors such as load capacity, speed, temperature, environmental conditions, and maintenance requirements should be taken into consideration to ensure optimal performance and longevity of the bearing.

Where can I purchase block bearings?

If you are looking to purchase block bearings, there are several options available to you. Here’s a detailed explanation of where you can purchase block bearings:

- Local Industrial Suppliers: One of the most convenient options is to check with local industrial suppliers or distributors in your area. These suppliers typically carry a wide range of bearings, including block bearings, and can provide you with the necessary guidance and support in selecting the right product for your specific application. You can search online directories or use search engines to find industrial suppliers near you.

- Bearing Manufacturers: Many bearing manufacturers have their own sales channels and online platforms where you can directly purchase block bearings. Some well-known bearing manufacturers include SKF, Timken, NSK, NTN, and FAG. Visiting the manufacturers’ websites will provide you with information on their authorized distributors, online stores, or contact details to inquire about purchasing options.

- Online Marketplaces: Online marketplaces like Amazon, eBay, and Alibaba offer a wide selection of block bearings from various sellers and suppliers. These platforms allow you to compare prices, read customer reviews, and choose from different brands and models. However, it’s important to ensure that you are purchasing from reputable sellers with positive ratings and reviews.

- Specialized Bearing Suppliers: There are specialized bearing suppliers that focus specifically on bearings and related products. These suppliers often have a comprehensive inventory of different types of bearings, including block bearings. They may have online stores or physical locations where you can make a purchase. Searching online for “specialized bearing suppliers” or “bearing distributors” will help you find such suppliers.

- Industrial Trade Shows and Exhibitions: Attending industrial trade shows and exhibitions related to machinery, bearings, or specific industries can provide an opportunity to connect with multiple suppliers and manufacturers in one place. These events often have exhibitors showcasing their products, including block bearings, and you can discuss your requirements directly with the representatives to make a purchase or gather information for future procurement.

- Local Machine Shops: Local machine shops or maintenance and repair service providers may stock block bearings for immediate purchase. These establishments often have a range of bearings available for quick replacement or repair needs. It’s worth checking with local machine shops in your area to inquire about their bearing inventory and purchasing options.

When purchasing block bearings, it’s important to consider factors such as the specific requirements of your application, the load capacity and speed rating of the bearing, the compatibility with your shaft diameter, and the quality and reputation of the supplier or manufacturer. It’s advisable to consult with experts or technical support from the supplier to ensure you select the right bearing for your needs.

Remember to compare prices, check for warranties or guarantees, and consider the shipping or delivery options before making a purchase decision.

editor by CX 2024-05-08

China manufacturer Linear Motion Bearing Brh30b Linear Block Bearings for CNC Machine with Best Sales

Product Description

High Speed Linear motion bearing Brh30b Linear Block Bearings for CNC Machine

Quick Details:

Xihu (West Lake) Dis. Width or Diameter: MAX 65mm as your request

Xihu (West Lake) Dis. Length: MAX 4000mm as your request

Model Number: BRH30B

Place of Origin: ZheJiang

Brand Name: ABBA

Grade: N, H, P

Application: CNC machine, automatic system

Sample: Available

Specifications:

ABBA linear CZPT rail and linear block bearing

1. Better than HIWIN

2. Superior quality and short delivery

3. Best price

ABBA linear CZPT advantage:

1. Built-in long life lubrication

2. Equal load capacities in 4 directions

3. Smooth running due to new ball re-circulation

4. High rigidity-4-row angular contact

5. International standard dimension

6. High accuracy Low friction Low maintenance.

7. High speed, low noise.

8. Integral all-round sealing.

9. Interchangeability.

10. Environment protection green production

ABBA linear CZPT Explanation

ABBA BRH25B linear guideway is a linear motion system for linear stroke and cylinder axis. Because the ball bearing and the bearing jacket point contact ball rolling with a minimum of friction, so linear guides have low friction, and relatively stable, with the bearing speed and change, it can be obtained with high sensitivity, high precision and smooth linear motion. Linear guides are widely used in precision machine tools, textile machinery, food packaging machinery, printing machinery and other industrial machinery sliding parts.

ABBA linear CZPT Application for

1. Suitable for very high rotating speeds

2. Well suited for medium high radial and axial loads in 1 or both directions

3. Various seals and grease variants available for different operating conditions

4. Numerous clearance and tolerance classes available for different operating conditions

5. Application examples: Electrical motors, general machinery, industrial gearboxes, pumps, agricultural machinery, etc.

6. Series—BRH, BRS, BCH, BCS, BCN, BMC, BR, BCRSR, RSH, MGW, VR…

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Magnetically |

|---|---|

| Function: | Super |

| Flange Shape: | Cutting-Edge |

| Shape: | Open |

| Series: | LME |

| Material: | Stainless Steel |

| Samples: |

US$ 5/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do I choose the right block bearing for my machinery?

Choosing the right block bearing for your machinery is crucial to ensure optimal performance, reliability, and longevity. Here’s a detailed explanation of the factors to consider when selecting a block bearing:

- Load Requirements: Determine the load requirements of your machinery, including the magnitude and direction of the loads that will be applied to the bearing. Consider factors such as static loads, dynamic loads, and shock loads. This information will help you choose a block bearing with the appropriate load-carrying capacity and load rating.

- Speed and Operating Conditions: Consider the speed at which your machinery will operate and the corresponding operating conditions. High-speed applications may require block bearings with specific design features, such as lower friction, improved heat dissipation, and higher precision. Additionally, assess the operating environment for factors like temperature, humidity, dust, and chemical exposure, as these can impact the choice of bearing materials and seals.

- Bearing Type and Configuration: Choose the appropriate bearing type and configuration based on your machinery’s requirements. Common types of block bearings include ball bearings, roller bearings, and spherical bearings. Consider factors such as the type of motion, misalignment compensation, and ease of installation when selecting the bearing type.

- Bearing Size and Shaft Diameter: Determine the required bearing size and shaft diameter for your machinery. The bearing should be properly sized to handle the loads and fit securely on the shaft. Refer to manufacturer guidelines or consult engineering resources to determine the appropriate bearing size and shaft diameter for your specific application.

- Sealing and Lubrication: Consider the sealing and lubrication requirements of your machinery. Sealing arrangements help protect the bearing from contaminants and retain lubrication. Choose the appropriate sealing options based on the operating environment and the desired level of protection. Additionally, select the right lubricant and lubrication method based on factors such as operating speed, temperature, and load conditions.

- Industry Standards and Regulations: Ensure that the selected block bearing complies with relevant industry standards and regulations. Compliance with standards such as ISO, ANSI, or ABMA ensures that the bearing meets quality and performance requirements.

- Consult Manufacturer or Supplier: If you are unsure about the appropriate block bearing for your machinery, consult the manufacturer or a reputable supplier. They can provide expert guidance, technical support, and recommend suitable products based on their experience and knowledge.

By considering these factors and seeking expert advice when needed, you can choose the right block bearing that matches the requirements of your machinery, ensuring reliable and efficient operation.

What are the signs of a failing block bearing?

A failing block bearing can exhibit various signs and symptoms that indicate potential issues. Recognizing these signs is crucial for timely maintenance or replacement to prevent further damage to the machinery. Here’s a detailed explanation of the common signs of a failing block bearing:

- Abnormal Noise: Unusual noises coming from the machinery, such as grinding, squealing, or rumbling sounds, can be indicative of a failing block bearing. These noises may occur during operation or when the machinery is under load.

- Vibration: Excessive vibration in the machinery can be a sign of a failing block bearing. If you notice increased levels of vibration during operation, especially in conjunction with other symptoms, it may indicate bearing wear or misalignment.

- Increased Temperature: A failing block bearing can generate excessive heat due to increased friction. If you observe abnormally high temperatures in the bearing housing or around the bearing area, it could be a sign of impending bearing failure.

- Irregular Operation: Changes in the smoothness or regularity of the machinery’s operation, such as intermittent or irregular motion, can be a result of a failing block bearing. This can manifest as jerky movements, sticking, or hesitation during operation.

- Loss of Lubrication: Insufficient or loss of lubrication can lead to bearing failure. If you notice signs of inadequate lubrication, such as dry or discolored lubricant, or if the bearing is running dry, it can accelerate wear and contribute to bearing failure.

- Visible Damage: Physical damage to the block bearing or its components, such as cracks, dents, or corrosion, can indicate a failing bearing. Additionally, if you observe excessive play or movement in the bearing, it may be a sign of wear or damage.

- Inconsistent Performance: A failing block bearing can result in inconsistent or reduced performance of the machinery. This may include decreased speed, reduced load-carrying capacity, or compromised precision in applications that require high accuracy.

- Increased Friction: If you notice an increase in friction or resistance when rotating or moving the machinery by hand, it may suggest a failing block bearing. Difficulty in turning the shaft or a feeling of roughness can indicate excessive wear or damage in the bearing.

It’s important to note that these signs can also be indicative of other issues in the machinery. Therefore, a thorough inspection by a qualified technician or engineer is recommended to accurately diagnose the problem. Regular maintenance, including visual inspections and monitoring of operating conditions, can help identify early signs of bearing failure and allow for timely intervention.

If you observe any of the mentioned signs, it’s crucial to address the issue promptly to prevent further damage to the machinery. Timely maintenance or replacement of failing block bearings can help ensure the continued reliable operation of the machinery and prevent costly breakdowns.

What is a block bearing?

A block bearing, also known as a pillow block bearing, is a type of bearing that is commonly used in various industrial applications. It is designed to provide support and smooth rotational motion to a shaft or rod while allowing it to move in a linear or oscillating manner. Here’s a detailed explanation of what a block bearing is:

A block bearing consists of two main parts: a housing and a bearing insert. The housing, typically made of cast iron or other sturdy materials, is a solid block-shaped structure with a mounting surface. It is designed to provide stability and support for the bearing insert. The bearing insert, which is usually a ball bearing or a roller bearing, is housed within the housing and is responsible for facilitating smooth rotational motion.

The housing of a block bearing is usually equipped with mounting holes or slots to enable easy installation and attachment to a support structure, such as a frame or housing. The mounting holes allow the block bearing to be securely fastened, keeping it in place during operation. Some block bearings also feature additional features such as grease fittings or seals to facilitate lubrication and prevent contaminants from entering the bearing.

Block bearings are commonly used in applications where there is a need to support and guide a rotating or oscillating shaft. They are often used in machinery and equipment such as conveyors, industrial fans, agricultural machinery, mining equipment, and more. Block bearings provide stability and help absorb radial and axial loads, allowing the shaft to rotate smoothly and efficiently.

One of the advantages of block bearings is their versatility. They are available in various sizes, configurations, and designs to accommodate different shaft diameters and load requirements. The bearing inserts can be interchangeably replaced, allowing for easy maintenance and replacement when needed. Additionally, block bearings can be used in different mounting positions, such as horizontal, vertical, or inclined, depending on the application requirements.

It’s important to select the appropriate block bearing based on the specific application requirements. Factors to consider include the load capacity, speed, operating conditions (such as temperature and humidity), and the compatibility of the bearing materials with the intended environment. Consulting the manufacturer’s specifications and guidelines is crucial to ensure the proper selection and installation of a block bearing.

editor by CX 2024-04-25

China Best Sales Pilloe Block Bearing UCFL206 Flange Units for Agricultural Machine with Great quality

Product Description

Pillow blocks, the most commonly used type of mounted units, are designed to provide shaft support where the mounting surface is parallel to the shaft axis. The bolt holes are usually slotted for adjustment during mounting. Pillow blocks are supplied in a variety of configurations. Pressed steel pillow block bearings are also available for light-duty applications.

| Bearing Unit No. | Shaft dia.(mm) | Dimensions(mm) | Bolt used(mm) | Bearing No. | Housing No. | Weight(kg) | ||||||||

| a | e | i | g | l | s | z | Bi | n | ||||||

| UCFL201 | 12 | 113 | 90 | 15 | 11 | 25.5 | 12 | 33.3 | 31 | 12.7 | M10 | UC201 | FL204 | 0.45 |

| UCFL202 | 15 | 113 | 90 | 15 | 11 | 25.5 | 12 | 33.3 | 31 | 12.7 | M10 | UC202 | FL204 | 0.44 |

| UCFL203 | 17 | 113 | 90 | 15 | 11 | 25.5 | 12 | 33.3 | 31 | 12.7 | M10 | UC203 | FL204 | 0.43 |

| UCFL204 | 20 | 113 | 90 | 15 | 11 | 25.5 | 12 | 33.3 | 31 | 12.7 | M10 | UC204 | FL204 | 0.4 |

| UCFL205 | 25 | 130 | 99 | 16 | 13 | 27 | 16 | 35.7 | 34.1 | 14.3 | M14 | UC205 | FL205 | 0.60 |

| UCFL206 | 30 | 148 | 117 | 18 | 13 | 31 | 16 | 40.2 | 38.1 | 15.9 | M14 | UC206 | FL206 | 0.80 |

| UCFL207 | 35 | 161 | 130 | 19 | 14 | 34 | 16 | 44.4 | 42.9 | 17.5 | M14 | UC207 | FL207 | 1.10 |

| UCFL208 | 40 | 175 | 144 | 21 | 14 | 36 | 16 | 51.2 | 49.2 | 19 | M14 | UC208 | FL208 | 1.30 |

| UCFL209 | 45 | 188 | 148 | 22 | 15 | 38 | 19 | 52.2 | 49.2 | 19 | M16 | UC209 | FL209 | 1.55 |

| UCFL210 | 50 | 197 | 157 | 22 | 15 | 40 | 19 | 54.6 | 51.6 | 19 | M16 | UC210 | FL210 | 1.75 |

| UCFL211 | 55 | 224 | 184 | 25 | 18 | 43 | 19 | 58.4 | 55.6 | 22.2 | M16 | UC211 | FL211 | 2.50 |

| UCFL212 | 60 | 250 | 202 | 29 | 18 | 48 | 23 | 68.7 | 65.1 | 25.4 | M20 | UC212 | FL212 | 3.30 |

| UCFL213 | 65 | 258 | 210 | 30 | 22 | 50 | 23 | 69.7 | 65.1 | 25.4 | M20 | UC213 | FL213 | 4.20 |

| UCFL214 | 70 | 265 | 216 | 31 | 22 | 54 | 23 | 75.4 | 74.6 | 30.2 | M20 | UC214 | FL214 | 4.80 |

| UCFL215 | 75 | 275 | 225 | 34 | 22 | 56 | 23 | 78.5 | 77.8 | 33.3 | M20 | UC215 | FL215 | 5.35 |

| UCFL216 | 80 | 290 | 233 | 34 | 22 | 58 | 25 | 83.3 | 82.6 | 33.3 | M22 | UC216 | FL216 | 6.68 |

| UCFL217 | 85 | 305 | 248 | 36 | 24 | 63 | 25 | 87.6 | 85.7 | 34.1 | M22 | UC217 | FL217 | 7.78 |

| UCFL218 | 90 | 320 | 265 | 40 | 24 | 68 | 25 | 96.3 | 96 | 39.7 | M22 | UC218 | FL218 | 9.31 |

Materials

The performance and reliability of rolling bearings are greatly affected by the materials which the bearing components are made from.BXY bearing rings and balls are made of high quality of GCr15 vacuum-degassed bearing steel.Chemical composition of GCr15 bearing steel is basically equivalent to some representative bearing steel as the chart shown below.

Chemical composition of high-carbon chrome bearing steel

| Standard Code | Material | Analysis(%) | ||||||

| C | Si | Mn | Cr | Mo | P | S | ||

| GB/T | GCr15 | 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | 1.40-1.65 | <=0.08 | <=0.571 | <=0.571 |

| DIN | 100Cr6 | 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | 1.40-1.65 | <=0.030 | <=0.571 | |

| ASTM | 52100 | 0.98-1.10 | 0.15-0.35 | 0.25-0.45 | 1.30-1.60 | <=0.10 | <=0.571 | <=0.571 |

| JIS | SUJ2 | 0.98-1.10 | 0.15-0.35 | <=0.50 | 1.30-1.60 | <=0.571 | <=0.571 | |

Most of ball bearing cages are made of cold rolled steel sheet.Anf for some bearing types and special applications,cages are made of glass fiber reinforced nylon 66 plastic,phenolic or machined brass.

The material of bearing housings is gray or ductile cas iron, housings can also be made of pressed steel,stainless steel, or engineering plastics for special purposes.

Operating temperature

The bearings usually operate below the temperature of 120ºC(the measuring temperature of the outer ring is 100ºC).Grease life reduction has to be taken into account when the bearings continue to operate at a temperatuer above 70ºC.The lowest operating temperature should not be lower than -10ºC.

For higher or lower temperature application,please consult us for further information.

Mounting method of housings

The desired installation order is :first install the housing,then the shaft and bearing.The bearing units can be easily installed in principle at any place.However, in order to have a long service life, it is desired that the mounting base is flat and rigid.

The pillow block type and flange type housing are desired that the angle between the surface on which the housing is mounted and the shaft be maintained to a tolerance of ±2°.

Products Packing

Our packaging is also very variable, the purpose is to meet the needs of different customers.The commonly used packages are as follows:

1.Industrial package+outer carton+pallets

2.Single box+outer carton+pallets

3.Tube package+middle box+outer carton+pallets

4.According to your requirements

Application

Pillow blcok Bearings are commonly used in agricultural machines such as grinder, drying machine, paper-machine, textile machine, woodworking machine, winch and roller conveyor as well as a large number of non agricultural applications.

OEM

Workplace

Guanxian Xinyan Pillow Block Bearing Co., Ltd. is based in ZheJiang (China) since 2011 and is 1 of the biggest authorized manufactures and exporters of bearing. We′ve been dedicated to provide all types of hiigh quality bearings to OEM, Retailers and traders throughout international market since the moment established.

Pillow block bearings, bearings housing, insert bearings and deep groove ball bearings are all we specialized. We are also developing nonstandard bearings as per the drawings from customers. Our dominant product is bearing unit. With the advantages of compact structure, Seld-aligning, well sealed, easy to equip, and reasonable prices. It s widely applied in machinery of agricultrure, chemical engineering, Mine, Metallurgy, Building, Light industry such as refrigeation, plastic, shoe-making, carpentry, Road, Building material, food, packing, textile, transportation, Printing, ceramics and so on.

Up to now, we have exported our goods to Italy, Brazil, Argentina, Poland, India, Pakistan, Bangladesh, Thailand etc.

First class service, efficient delivery methods, the most competitive quality-price ratio, we dedicated to provide you quality brand bearings. Sincerely welcome new and old customers visit and build cooperation. Our goal is to establish first class company, create world famous brand, The policy in quality is that the need of the maket is our direction, pursuing to meet customers satisfaction, Improving constantly, working practically and creatively and serving the society. We form the sprit of connecting together to improve and to help you to success.

BXY is our registered brand. And warmly welcome to CZPT Bearing Co., Ltd and Lets expand BXY market together!

NO.1

We are factory directly.

NO.2

We provide our customers the most Comprehensive service and we’ll do our best to deal with problems our customers encountered to ensure our customers SATISFACTION.

NO.3

The high quality of our products means that it has long life, high speed, low noise, low vibration and low friction.

NO.4

Be honesty, be professional is our faith; good attitude, timely response, quick delivery, consideration of every detail is our working style.

NO.5

Manufactured by ourselves, enough storage space, enough inventory, high producing efficiency we possess, the most favorable price we offer to our customers makes sure every deal have a happy end.

Customer’s feedback

The company is from the original steel, forging, turning, quenching, fine grinding, installation, one-stop production line, to ensure the quality of steel, bearing size specifications, installation technology, at a low price to ensure the quality of bearing.We will deliver the goods on a fast delivery date.To ensure your use and sale.Omitted the middle link, let you more affordable…

Customer’s evaluation is the standard of product quality inspection, we always adhere to the customer matching the corresponding quality requirements of the product, responsible for the customer.In the premise of quality assurance to customers, we try to achieve a ‘popular’ price.

Exhibition

FAQ

Q1: How many the MOQ of your company?

A: Our company MOQ is 1pcs.

Q2: Could you accept OEM and customize?

A:YES, we can customize for you according to sample or drawing.

Q3: Could you supply sample for free?

A: Yes, we can supply sample for free, but need our customer afford freight.

Q4 : Does your factory have CE?

A: Yes, we have ISO 9001:2008, and SASO. If you want other CE, we can do for you.

Q5: Is it your company is factory or Trade Company?

A: We have our own factory; our type is factory + trade.

Q6: What time the guarantee of your bearing quality guarantee period?

A: 6 months ,Customer need supply photos and send bearing back.

Q7: Could you tell me the payment term of your company can accept?

A: T/T, Western Union, PayPal, T/T, L/C.

Q8: Could you tell me the delivery time of your goods?

A: 7-15 days , mostly base on your order quantity.

WELCOME TO INQUIRY!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Aligning Bearing |

|---|---|

| Separated: | Separated |

| Feature: | Low Temperature, Corrosion Resistant, High Temperature, High Speed |

| Rows Number: | Single |

| Raceway: | Deep Groove Raceway |

| Material: | Bearing Steel |

| Customization: |

Available

| Customized Request |

|---|

How do I choose the right block bearing for my machinery?

Choosing the right block bearing for your machinery is crucial to ensure optimal performance, reliability, and longevity. Here’s a detailed explanation of the factors to consider when selecting a block bearing:

- Load Requirements: Determine the load requirements of your machinery, including the magnitude and direction of the loads that will be applied to the bearing. Consider factors such as static loads, dynamic loads, and shock loads. This information will help you choose a block bearing with the appropriate load-carrying capacity and load rating.

- Speed and Operating Conditions: Consider the speed at which your machinery will operate and the corresponding operating conditions. High-speed applications may require block bearings with specific design features, such as lower friction, improved heat dissipation, and higher precision. Additionally, assess the operating environment for factors like temperature, humidity, dust, and chemical exposure, as these can impact the choice of bearing materials and seals.

- Bearing Type and Configuration: Choose the appropriate bearing type and configuration based on your machinery’s requirements. Common types of block bearings include ball bearings, roller bearings, and spherical bearings. Consider factors such as the type of motion, misalignment compensation, and ease of installation when selecting the bearing type.

- Bearing Size and Shaft Diameter: Determine the required bearing size and shaft diameter for your machinery. The bearing should be properly sized to handle the loads and fit securely on the shaft. Refer to manufacturer guidelines or consult engineering resources to determine the appropriate bearing size and shaft diameter for your specific application.

- Sealing and Lubrication: Consider the sealing and lubrication requirements of your machinery. Sealing arrangements help protect the bearing from contaminants and retain lubrication. Choose the appropriate sealing options based on the operating environment and the desired level of protection. Additionally, select the right lubricant and lubrication method based on factors such as operating speed, temperature, and load conditions.

- Industry Standards and Regulations: Ensure that the selected block bearing complies with relevant industry standards and regulations. Compliance with standards such as ISO, ANSI, or ABMA ensures that the bearing meets quality and performance requirements.

- Consult Manufacturer or Supplier: If you are unsure about the appropriate block bearing for your machinery, consult the manufacturer or a reputable supplier. They can provide expert guidance, technical support, and recommend suitable products based on their experience and knowledge.

By considering these factors and seeking expert advice when needed, you can choose the right block bearing that matches the requirements of your machinery, ensuring reliable and efficient operation.

Are there different grades or types of block bearings?

Yes, there are different grades and types of block bearings available to suit various applications and operating conditions. Block bearings, also known as pillow block bearings or plummer block bearings, come in a range of designs and configurations to accommodate different shaft sizes, loads, speeds, and environmental factors. Here are some common grades and types of block bearings:

1. Standard Duty Block Bearings: Standard duty block bearings are commonly used in general applications with moderate loads and speeds. They are designed to provide reliable support for rotating shafts in a wide range of industries and machinery.

2. Heavy Duty Block Bearings: Heavy duty block bearings are specifically designed to handle higher loads and more demanding operating conditions compared to standard duty bearings. They are suitable for applications that involve heavy loads, shock loads, or high-speed rotation.

3. High-Temperature Block Bearings: High-temperature block bearings are designed to withstand elevated temperatures without compromising their performance or longevity. They are commonly used in applications where the operating temperatures exceed the capabilities of standard bearings.

4. Corrosion-Resistant Block Bearings: Corrosion-resistant block bearings are made from materials or coatings that provide protection against corrosive environments. These bearings are used in industries such as food processing, chemical processing, or marine applications where exposure to moisture, chemicals, or other corrosive agents is a concern.

5. Split Block Bearings: Split block bearings feature a housing that can be split into two or more pieces, allowing for easier installation and maintenance. They are often used in applications where it is difficult to access or remove the bearing without disassembling other components.

6. Self-Aligning Block Bearings: Self-aligning block bearings have a spherical outer diameter that allows for self-alignment, compensating for minor shaft misalignments. These bearings are suitable for applications where shaft deflection or misalignment is expected.

7. Flange Block Bearings: Flange block bearings have a flanged housing that provides additional support and stability. They are commonly used in applications where the bearing needs to be bolted to a structure or where space constraints limit the use of traditional block bearings.

8. Specialty Block Bearings: There are also specialty block bearings designed for specific applications or industries. For example, there are block bearings optimized for high-speed applications, extreme temperatures, vacuum environments, or specific industries like mining or agriculture.

It’s important to consult the manufacturer’s specifications and guidelines to select the appropriate grade and type of block bearing for a specific application. Factors such as load capacity, speed, temperature, environmental conditions, and maintenance requirements should be taken into consideration to ensure optimal performance and longevity of the bearing.

What are the common applications of block bearings?

Block bearings, also known as pillow block bearings, are widely used in various industrial applications where there is a need to support and guide rotating or oscillating shafts. These bearings offer stability, load-carrying capacity, and ease of installation. Here’s a detailed explanation of the common applications of block bearings:

- Conveyor Systems: Block bearings are extensively used in conveyor systems found in industries such as manufacturing, mining, and logistics. They provide support and smooth motion for the conveyor belts, allowing efficient material handling and transportation.

- Fans and Blowers: Block bearings are commonly employed in industrial fans, blowers, and HVAC systems. They help support the rotating shafts of the fan blades, ensuring smooth operation and minimizing vibration.

- Pumps and Compressors: Block bearings find applications in pumps and compressors, where they support the rotating shafts and help maintain the fluid or gas flow. These bearings are essential for efficient operation and reliability in various industries, including oil and gas, water treatment, and HVAC.

- Agricultural Machinery: Block bearings are used in agricultural equipment such as harvesters, tractors, and irrigation systems. They provide support for shafts and rotating components, enabling efficient operation in demanding agricultural environments.

- Food Processing Equipment: The food processing industry often utilizes block bearings in equipment like mixers, conveyors, and packaging machinery. The bearings used in these applications are typically made of food-grade materials and designed to withstand frequent cleaning and sanitization.

- Material Handling Equipment: Block bearings are employed in a wide range of material handling equipment, including forklifts, cranes, and hoists. These bearings support the shafts and mechanisms involved in lifting, moving, and positioning heavy loads.

- Mining and Construction Machinery: Block bearings are used in heavy-duty equipment found in the mining and construction industries. They provide support and smooth rotation for components like conveyor systems, crushers, and excavators, enabling efficient operation in harsh environments.

- Printing and Packaging Machinery: Block bearings are utilized in printing presses, packaging machines, and paper processing equipment. They help support the rotating shafts and rollers, ensuring precise motion and reliable operation during printing, packaging, and paper handling processes.

- Textile Machinery: Block bearings are commonly employed in textile machinery, including spinning machines, weaving looms, and dyeing equipment. They support the rotating shafts and spindles, allowing smooth and precise movement during textile production processes.

- Automotive and Transportation: Block bearings are used in various automotive applications, such as wheel hubs, suspension systems, and transmission components. They provide support and enable smooth rotation in the automotive industry, ensuring reliable performance and comfort.

These are just a few examples of the common applications of block bearings. Due to their versatility, durability, and ability to handle substantial loads, block bearings are employed in numerous industries and equipment types where rotational motion support is required.

editor by CX 2024-04-16

China Custom Bf Bk Ball Screw End Supports Bearing Mounts Blocks CNC Bk Bf 10 12 15 for 3D CNC Router Machine wheel bearing

Product Description

Product Description

SHAC brand Ball screw support, containing for subminiature ball screw developed by contact Angle 45 subminiature angular contact ball bearings, can obtain high rigidity, high precision of steady turning performance.Support the lateral support unit use deep groove ball bearings.Support unit such as EK, BK type internal bearing load of the right amount of lithium soap grease, with a special seal gasket to seal, can be installed directly, can use for a long time.

| Brand | SHAC,TXP |

| Model | BK/BF/EK/EF/FK/FF/WBK |

| Precision Rating | C7/C5/C3 |

| Material | Carbon steel,bearings steel |

| Customeized | OEM,ODM |

| Packing | Plastic bag+inner box.According to customer’s request |

| Sample | Free sample and catalogue available |

| Certification | SGS, ISO9001,ISO14001,OHSAS18001 |