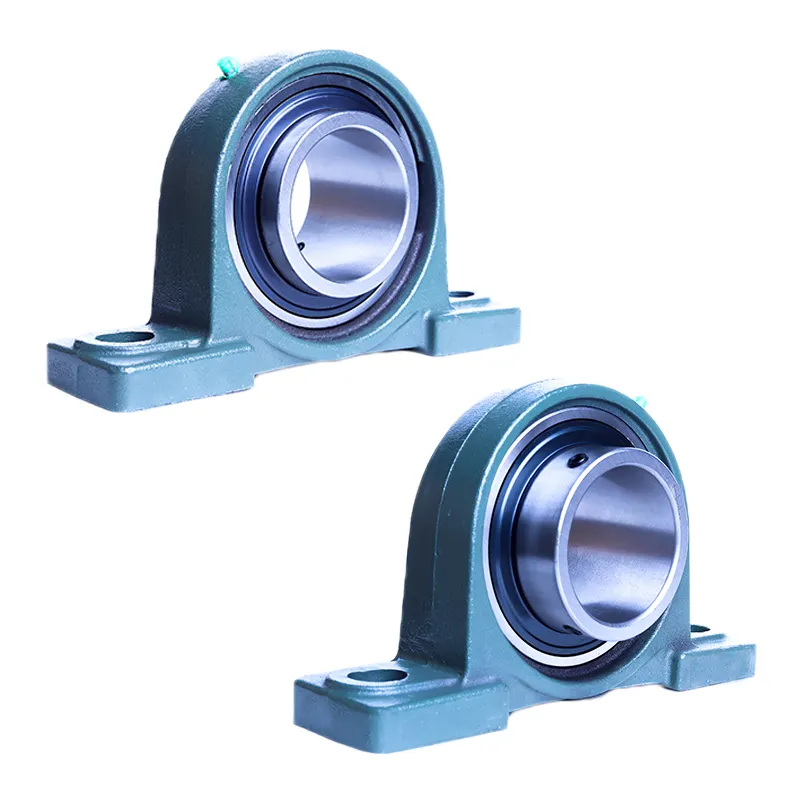

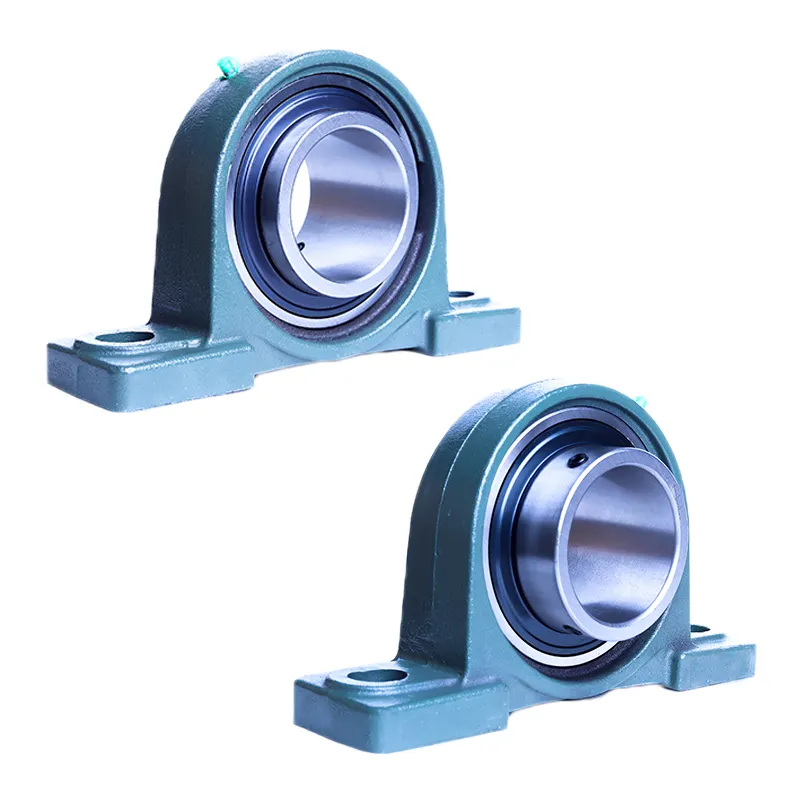

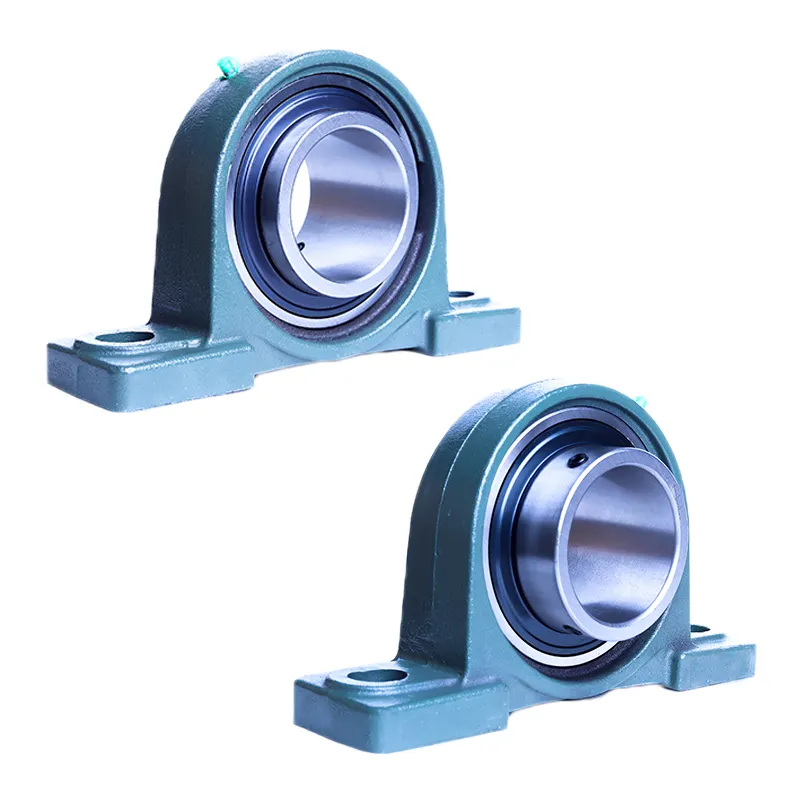

Product Description

Linear Bearing

| Rows Number | Single | Load Direction | Radial Bearing |

| Material | Bearing Steel | Precision Rating | PO P6 P5 P4 P2 |

| Clearance | CO C1 C2 C3 C4 | Lubrication | Oil Lubrication |

| OEM | Available | Hardness | 59-63HRC |

| Feature | High Speed,Long Life | Transport Package | Single Box |

| Specification | standard | Trademark | Packing |

| Production Capacity | 1500,000 Pieces/Year |

Linear bearings are a linear motion system used with cylindrical shafts for linear travel. Since the load-bearing ball is in point contact with the bearing jacket, the steel ball rolls with minimal frictional resistance. Therefore, the linear bearing has low friction and is relatively stable. It does not change with the bearing speed and can obtain smooth linear motion with high sensitivity and high precision. Linear bearings are widely used in sliding parts of industrial machinery such as precision machine tools, textile machinery, food packaging machinery, and printing machinery.

Production Line

HangZhou Siruibo Bearing Technology Co., Ltd. is a company mainly engaged in manufacturing and selling outer spherical bearings. The registered capital is Five million.

Since its establishment 20 years ago, the company is committed to Mounted Bearing Unit (maintenance-free bearings, engraving machine bearings, holding machine shaft Bearing, no-tillage machine bearing, fan bearing, high temperature bearing, zinc alloy bearing, food grade bearing unit) research and development. With the most complete varieties and best advanced manufacturing technology in production of Mounted Bearing Unit, to be a reliable enterprises, we welcome your cooperation. Currently, our company produce 10 series of more than 260 varieties of outer spherical bearings and 13 different structural categories of outer spherical bearing special seats, all adopted International standard design and manufacturing. Registered trademark “FOS” .

Through the efforts and unremitting pursuit of all employees of the company, all products accepted by international standards. Over the years of Expansion and technical transformation, we developed into a Mounted Bearing Unit with large scale of professional manufacturers, for the bearing industry in China, has made a contribution to the development of Bearing.

HangZhou Siruibo Bearing Technology Co., Ltd. has a production capacity of 1 million sets/year, with an annual output value of 30 million yuan. We produce 30 varieties monthly , with 45-60 days lead time.

The company has a perfect material and product quality inspection equipment, according to the strict scientific Quality assurance system, to prove satisfactory to our customers. Our products widely used in agricultural Industry machinery, textile machinery and light industry, chemical industry, metallurgy, printing, food, transportation, coal, packaging and other industries and the introduction of machinery .Our products have exported to Europe, America and many countries and regions in South east Asia.

Exhibitions

About us:

We are 1 manufactuer of bearing for more than 20 years.

Give us a chance, we will cooperate with our passion.

Our professional, reliable, experienced products and service can meet your request.

Why choose us?

SAMPLES

1. Samples quantity: 1-10 PCS are available.

2. Free samples: It depends on the Model No., material and quantity. Some of the bearings samples need client to pay samples charge and shipping cost.

3. It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1. MOQ: 10 PCS mix different standard bearings.

2. MOQ: 3000 PCS customized your brand bearings.

OEM POLICY

1. We can printing your brand (logo, artwork)on the shield or laser engraving your brand on the shield.

2. We can custom your packaging according to your design

3. All copyright own by clients and we promised don’t disclose any info.

SUPORT

Please visit our bearings website, we strongly encourge that you can communicate with us through email, thanks!

We have all kinds of bearings, just tell me your item number and quantity, best price will be offered to you soon

The material of the bearings, precision rating, seals type, OEM service, etc, all of them we can make according to your requirement.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Vacuum, Magnetically, Low Temperature, Corrosion Resistant, High Temperature, High Speed |

|---|---|

| Function: | Super |

| Flange Shape: | Oval |

| Shape: | Flange |

| Series: | LM |

| Material: | Bearing Steel |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do I choose the right block bearing for my machinery?

Choosing the right block bearing for your machinery is crucial to ensure optimal performance, reliability, and longevity. Here’s a detailed explanation of the factors to consider when selecting a block bearing:

- Load Requirements: Determine the load requirements of your machinery, including the magnitude and direction of the loads that will be applied to the bearing. Consider factors such as static loads, dynamic loads, and shock loads. This information will help you choose a block bearing with the appropriate load-carrying capacity and load rating.

- Speed and Operating Conditions: Consider the speed at which your machinery will operate and the corresponding operating conditions. High-speed applications may require block bearings with specific design features, such as lower friction, improved heat dissipation, and higher precision. Additionally, assess the operating environment for factors like temperature, humidity, dust, and chemical exposure, as these can impact the choice of bearing materials and seals.

- Bearing Type and Configuration: Choose the appropriate bearing type and configuration based on your machinery’s requirements. Common types of block bearings include ball bearings, roller bearings, and spherical bearings. Consider factors such as the type of motion, misalignment compensation, and ease of installation when selecting the bearing type.

- Bearing Size and Shaft Diameter: Determine the required bearing size and shaft diameter for your machinery. The bearing should be properly sized to handle the loads and fit securely on the shaft. Refer to manufacturer guidelines or consult engineering resources to determine the appropriate bearing size and shaft diameter for your specific application.

- Sealing and Lubrication: Consider the sealing and lubrication requirements of your machinery. Sealing arrangements help protect the bearing from contaminants and retain lubrication. Choose the appropriate sealing options based on the operating environment and the desired level of protection. Additionally, select the right lubricant and lubrication method based on factors such as operating speed, temperature, and load conditions.

- Industry Standards and Regulations: Ensure that the selected block bearing complies with relevant industry standards and regulations. Compliance with standards such as ISO, ANSI, or ABMA ensures that the bearing meets quality and performance requirements.

- Consult Manufacturer or Supplier: If you are unsure about the appropriate block bearing for your machinery, consult the manufacturer or a reputable supplier. They can provide expert guidance, technical support, and recommend suitable products based on their experience and knowledge.

By considering these factors and seeking expert advice when needed, you can choose the right block bearing that matches the requirements of your machinery, ensuring reliable and efficient operation.

Can block bearings handle both radial and axial loads?

Yes, block bearings are designed to handle both radial and axial loads. Block bearings, also known as pillow block bearings or plummer block bearings, are a type of bearing housing that contains a rolling element bearing. These bearings are commonly used in various industrial applications to support rotating shafts and provide support for both radial and axial loads.

The design of block bearings allows them to accommodate radial loads, which are forces acting perpendicular to the shaft’s axis. Radial loads can be caused by the weight of the shaft, the load being transmitted through the shaft, or other external forces acting on the bearing.

In addition to radial loads, block bearings are also capable of handling axial loads, which are forces acting parallel to the shaft’s axis. Axial loads can be caused by thrust or pushing/pulling forces exerted on the bearing. The ability of block bearings to handle axial loads depends on their specific design and configuration.

Block bearings typically consist of a housing (block) and an insert bearing. The housing provides support and protection for the bearing, while the insert bearing is the rolling element bearing that carries the load. The insert bearing can be designed to handle both radial and axial loads, depending on its type and construction.

Some block bearings use deep groove ball bearings as the insert bearing, which are capable of handling both radial and axial loads. Other types of insert bearings, such as spherical roller bearings or tapered roller bearings, are specifically designed to handle higher axial loads in addition to radial loads.

It’s important to consider the specific application requirements and load conditions when selecting block bearings. The manufacturer’s specifications and guidelines should be consulted to ensure that the chosen block bearings are suitable for the expected radial and axial load capacities.

Overall, block bearings are designed to provide support for both radial and axial loads, making them versatile and widely used in various machinery and equipment applications.

How is a block bearing different from other types of bearings?

A block bearing, also known as a pillow block bearing, has several distinct characteristics that differentiate it from other types of bearings. Here’s a detailed explanation of how a block bearing differs from other bearing types:

1. Housing Design: One of the key differences of a block bearing is its housing design. A block bearing features a solid block-shaped housing that provides support and stability to the bearing insert. This housing is typically made of materials like cast iron, stainless steel, or thermoplastics, and it often has mounting holes or slots for easy installation onto a support structure.

2. Mounting: Block bearings are designed to be easily mounted and secured onto a support structure, such as a frame or housing. The housing of a block bearing has mounting holes or slots that allow for straightforward attachment using bolts or fasteners. This mounting design provides stability and ensures that the bearing remains in place during operation.

3. Bearing Insert: Another distinct feature of a block bearing is the bearing insert it uses. The bearing insert in a block bearing is typically a ball bearing or a roller bearing. These bearing inserts are designed to facilitate smooth rotational motion of a shaft or rod while providing support and load-carrying capacity.

4. Application: Block bearings are commonly used in applications where there is a need to support and guide a rotating or oscillating shaft. They are widely utilized in various industrial machinery and equipment, such as conveyors, fans, pumps, agricultural machinery, and mining equipment. The block bearing’s robust design and ability to handle radial and axial loads make it suitable for these types of applications.

5. Versatility: Block bearings offer versatility in terms of size, configuration, and design. They are available in different sizes to accommodate various shaft diameters and load requirements. Additionally, block bearings can be used in different mounting positions, such as horizontal, vertical, or inclined, depending on the specific application needs.

6. Maintenance: Block bearings generally require regular maintenance, including lubrication, to ensure optimal performance and longevity. Lubrication helps reduce friction and wear between the bearing components, ensuring smooth operation. Many block bearings feature grease fittings or seals that allow for easy lubrication and help protect the bearing from contaminants.

While block bearings have their unique characteristics, it’s important to note that there are many other types of bearings available, each with its own advantages and applications. Some common types of bearings include deep groove ball bearings, cylindrical roller bearings, tapered roller bearings, and spherical roller bearings. The selection of the appropriate bearing type depends on factors such as load capacity, speed, operating conditions, and specific application requirements.

By understanding the differences between various bearing types, it becomes easier to select the most suitable bearing for a particular application.

editor by CX 2024-05-15

China supplier Linear Motion Guide HGH35 Ca HGH35ca HGH35 Ha Carriage Block Bearing bearing driver kit

Product Description

Linear motion CZPT HGH35 CA HGH35CA HGH35 HA Carriage Block Bearing

. HIWIN offers 2 types of linear guideway which are flange and square types. Because of the low assembly height and larger mounting surface, the flange type is suitable for heavy moment load application.

. HIWIN linear slide rail is a kind of rolling guide, it is composed of steel ball between slide block and the slide rail for the infinite scroll circulation, make the load platform can easily along the slide rail with high precision linear motion, the coefficient of friction can be reduced to 1/50 of the traditional sliding guide, make it can easily reach mu m class location accuracy.Between slide block and the slide rail making yuan at the end of the design, make the linear slide rail can be under the direction of the up and down or so and so on various load at the same time, the recycling of patent system and streamlined structure design makes HIWIN linear slide rail with more smooth and low noise.

. HG series guideways can be classified into non-interchangeable and interchangeable types. The sizes are identical. The only difference between the 2 types is that the interchangeable type of blocks and rails can be freely exchanged, and their accuracy can reach up to p class. The model number of HG series contains the size, type, accuracy class, preload class, etc.

|

Product Name |

HGH35CA Low price precise HIWIN linear CZPT rail HGH 35HA |

|

Material |

stainless steel |

|

Quality |

high speed, high accuracy and smooth linear motion. |

|

Features of HG Series |

Self-aligning capability,Interchangeability, High rigidity in all 4 directions |

|

Grade |

P |

|

Brand Name |

HIWIN |

|

Block Series |

HGH15CA/HGH20CA/HGH20HA/HGH25CA/HGH25HA/HGH30CA/HGH30HA/HGH35CA/HGH35HA/HGH45CA/HGH45HA/HGH55CA/HGH55HA/HGH65CA/HGH65HA |

|

Lubrication |

Grease,Oil |

HGH35CA Low price precise HIWIN linear CZPT rail HGH 35HA Features of HG Series

(1) Self-aligning capability

By design, the circular-arc groove has contact points at 45 degrees. HG series can absorb most installation errors due to surface irregularities and provide smooth linear motion through the elastic deformation of rolling elements and the shift of contact points. self-aligning capability, high accuracy and smooth operation can be obtained with an easy installation..

(2) Interchangeability

Because of precision dimensional control, the dimensional tolerance of HG series can be kept in a reasonable range, which means that any blocks and any rails in a specific series can be used together while maintaining dimensional tolerance. And a retainer is added to prevent the balls from falling out when the blocks are removed from the rail.

(3) High rigidity in all 4 directions

Because of the four-row design, the HG series linear guideway has equal load ratings in the radial, reverse radial and lateral directions. furthermore, the circular-arc groove provides a wide-contact width between the balls and the groove raceway allowing large permissible loads and high rigidity.

Why choose us ?

1. Quality Control To ensure the quality of our vehicles and other products, Our QC staffs do strict supplier evaluations, in-coming inspections, in-process inspections, final inspections and pre-delivery inspections. The most important is that we listen to what our customers say and are always looking for ways to improve the quality of our products through continuous improvement.

2. OEM Ability We have built stable and long-term cooperate relationshilp with supermarkets,we canalso provide ODM, OEM and Agent services to our customers over the world.

3. Parts Available We have spare bearings for immediate delivery to anywhere in the world. Our Bearings widely used in the fields of motor, fan, injection molding machine, mining, mechanical equipment, metallurgy, rolling, automobile, railway, iron and steel, power, textile, packaging, petroleum, paper making, etc

4. Good Warranty We take customer satisfaction and product quality as the first priority for us. We supply reliable warranties and good after-sales services.

1. Quality Control To ensure the quality of our vehicles and other products, Our QC staffs do strict supplier evaluations, in-coming inspections, in-process inspections, final inspections and pre-delivery inspections. The most important is that we listen to what our customers say and are always looking for ways to improve the quality of our products through continuous improvement.

2. OEM Ability We have built stable and long-term cooperate relationshilp with supermarkets,we canalso provide ODM, OEM and Agent services to our customers over the world.

3. Parts Available We have spare bearings for immediate delivery to anywhere in the world. Our Bearings widely used in the fields of motor, fan, injection molding machine, mining, mechanical equipment, metallurgy, rolling, automobile, railway, iron and steel, power, textile, packaging, petroleum, paper making, etc

4. Good Warranty We take customer satisfaction and product quality as the first priority for us. We supply reliable warranties and good after-sales services.

F A Q

*Q:Can I get samples from you?

A:We are honored to offer you samples for quality check.

*Q:What parts are manufactured by you?

A: :90% of bearings are manufactured by us.

*Q:What’s the leading time? (How long do you need to prepare my goods?)

A:10 days for sample orders. 30 days for mass production orders (based on different quantities)

*Q:How long do I need to wait before my goods arrive?

A:3-5 days for international express. 5-7 days for air transportation, 35-40 days for sea transportation.

*Q:Can you put my brand name (logo) on these products?

A: Yes, or container order. Sticker order qty over 100pcs.

*Q:What payment methods do you accept?

A:T/T, L/C, Western Union, etc.

*Q:What certificates do you have?

A: All of our products are with CE IAF certificate. For some models, the certificates are already available. For other models, we will need your assistance to apply the certificates. For some models, the certificates are already available. For other models, we will need your assistance to apply the certificates.

*Q:What is your product quality?

A:Our raw materials are purchased from qualified suppliers. And we have a strong quality control team to guarantee our quality. We always care what you care!!

*Q:What is your warranty?

A:Our warranty is 24 months after delivery. We always pay high attention to after sale service!! For those out of warranty, we have adequate parts.

Electrical and easy wear parts are not included in warranty range.

*Q:How are parts availability?

A:We keep stock of spare parts and make sure all parts available whenever you need. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Bearing Steel |

|---|---|

| Feature: | High Speed |

| Function: | Super |

| Flange Shape: | Square |

| Shape: | Straight |

| Series: | Lme |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What materials are typically used in the manufacturing of block bearings?

Block bearings, also known as pillow block bearings, are manufactured using a variety of materials to meet different application requirements and operating conditions. Here’s a detailed explanation of the materials that are typically used in the manufacturing of block bearings:

1. Bearing Housing Materials: The housing of a block bearing, also called an outer ring or pillow block, is responsible for providing support and protection to the bearing insert. Common materials used for bearing housings include:

- Cast Iron: Cast iron is a popular material for bearing housings due to its excellent strength, rigidity, and durability. It provides good resistance to shock, vibration, and corrosion. Cast iron housings are commonly used in heavy-duty applications.

- Steel: Steel housings offer high strength and toughness, making them suitable for applications with demanding operating conditions. They provide good resistance to impact, wear, and corrosion.

- Stainless Steel: Stainless steel housings are used in applications where corrosion resistance is critical. They are particularly suitable for environments with high humidity, moisture, or chemical exposure.

- Thermoplastic: Thermoplastic housings, typically made of materials such as polyamide or PBT (polybutylene terephthalate), offer excellent chemical resistance and can be suitable for applications where lightweight, non-metallic housings are required.

2. Bearing Insert Materials: The bearing insert, also known as the inner ring, is the component that directly interacts with the rotating shaft. Common materials used for bearing inserts include:

- Chrome Steel: Chrome steel, also known as bearing steel, is a common material for bearing inserts. It offers good hardness, wear resistance, and load-carrying capacity. Chrome steel inserts are suitable for a wide range of applications.

- Stainless Steel: Stainless steel inserts are used in applications where corrosion resistance is crucial. They provide good resistance to moisture, chemicals, and high-temperature environments.

- Ceramic: Ceramic inserts, typically made of materials like silicon nitride or zirconia, offer exceptional hardness, corrosion resistance, and high-temperature capabilities. Ceramic bearings are used in specialized applications that require extreme performance.

3. Lubrication: While not a material used in the construction of block bearings, lubricants play a critical role in their operation. Lubricants, such as grease or oil, are used to reduce friction, dissipate heat, and protect against wear. The selection of the appropriate lubricant depends on factors like operating speed, temperature, and load conditions.

It’s important to note that the specific materials used in the manufacturing of block bearings can vary depending on the manufacturer, application requirements, and industry standards. When selecting a block bearing, it’s advisable to consult the manufacturer’s specifications and guidelines to ensure the chosen materials are suitable for your specific needs.

Are there different grades or types of block bearings?

Yes, there are different grades and types of block bearings available to suit various applications and operating conditions. Block bearings, also known as pillow block bearings or plummer block bearings, come in a range of designs and configurations to accommodate different shaft sizes, loads, speeds, and environmental factors. Here are some common grades and types of block bearings:

1. Standard Duty Block Bearings: Standard duty block bearings are commonly used in general applications with moderate loads and speeds. They are designed to provide reliable support for rotating shafts in a wide range of industries and machinery.

2. Heavy Duty Block Bearings: Heavy duty block bearings are specifically designed to handle higher loads and more demanding operating conditions compared to standard duty bearings. They are suitable for applications that involve heavy loads, shock loads, or high-speed rotation.

3. High-Temperature Block Bearings: High-temperature block bearings are designed to withstand elevated temperatures without compromising their performance or longevity. They are commonly used in applications where the operating temperatures exceed the capabilities of standard bearings.

4. Corrosion-Resistant Block Bearings: Corrosion-resistant block bearings are made from materials or coatings that provide protection against corrosive environments. These bearings are used in industries such as food processing, chemical processing, or marine applications where exposure to moisture, chemicals, or other corrosive agents is a concern.

5. Split Block Bearings: Split block bearings feature a housing that can be split into two or more pieces, allowing for easier installation and maintenance. They are often used in applications where it is difficult to access or remove the bearing without disassembling other components.

6. Self-Aligning Block Bearings: Self-aligning block bearings have a spherical outer diameter that allows for self-alignment, compensating for minor shaft misalignments. These bearings are suitable for applications where shaft deflection or misalignment is expected.

7. Flange Block Bearings: Flange block bearings have a flanged housing that provides additional support and stability. They are commonly used in applications where the bearing needs to be bolted to a structure or where space constraints limit the use of traditional block bearings.

8. Specialty Block Bearings: There are also specialty block bearings designed for specific applications or industries. For example, there are block bearings optimized for high-speed applications, extreme temperatures, vacuum environments, or specific industries like mining or agriculture.

It’s important to consult the manufacturer’s specifications and guidelines to select the appropriate grade and type of block bearing for a specific application. Factors such as load capacity, speed, temperature, environmental conditions, and maintenance requirements should be taken into consideration to ensure optimal performance and longevity of the bearing.

Where can I purchase block bearings?

If you are looking to purchase block bearings, there are several options available to you. Here’s a detailed explanation of where you can purchase block bearings:

- Local Industrial Suppliers: One of the most convenient options is to check with local industrial suppliers or distributors in your area. These suppliers typically carry a wide range of bearings, including block bearings, and can provide you with the necessary guidance and support in selecting the right product for your specific application. You can search online directories or use search engines to find industrial suppliers near you.

- Bearing Manufacturers: Many bearing manufacturers have their own sales channels and online platforms where you can directly purchase block bearings. Some well-known bearing manufacturers include SKF, Timken, NSK, NTN, and FAG. Visiting the manufacturers’ websites will provide you with information on their authorized distributors, online stores, or contact details to inquire about purchasing options.

- Online Marketplaces: Online marketplaces like Amazon, eBay, and Alibaba offer a wide selection of block bearings from various sellers and suppliers. These platforms allow you to compare prices, read customer reviews, and choose from different brands and models. However, it’s important to ensure that you are purchasing from reputable sellers with positive ratings and reviews.

- Specialized Bearing Suppliers: There are specialized bearing suppliers that focus specifically on bearings and related products. These suppliers often have a comprehensive inventory of different types of bearings, including block bearings. They may have online stores or physical locations where you can make a purchase. Searching online for “specialized bearing suppliers” or “bearing distributors” will help you find such suppliers.

- Industrial Trade Shows and Exhibitions: Attending industrial trade shows and exhibitions related to machinery, bearings, or specific industries can provide an opportunity to connect with multiple suppliers and manufacturers in one place. These events often have exhibitors showcasing their products, including block bearings, and you can discuss your requirements directly with the representatives to make a purchase or gather information for future procurement.

- Local Machine Shops: Local machine shops or maintenance and repair service providers may stock block bearings for immediate purchase. These establishments often have a range of bearings available for quick replacement or repair needs. It’s worth checking with local machine shops in your area to inquire about their bearing inventory and purchasing options.

When purchasing block bearings, it’s important to consider factors such as the specific requirements of your application, the load capacity and speed rating of the bearing, the compatibility with your shaft diameter, and the quality and reputation of the supplier or manufacturer. It’s advisable to consult with experts or technical support from the supplier to ensure you select the right bearing for your needs.

Remember to compare prices, check for warranties or guarantees, and consider the shipping or delivery options before making a purchase decision.

editor by CX 2024-05-10

China supplier Original PMI Msa20 Linear Guide Slide Bearing Msa 20 Lm Linear Motion Guide Block Bearing connecting rod bearing

Product Description

PMI LM Block / Carriage / Rail / Linear Xihu (West Lake) Dis.

| Procuct Name | Original PMI LM Xihu (West Lake) Dis. |

| Material | Chrome Steel/ Stainless Steel |

| Brand Name | PMI |

| Features | High speed, energy saving |

MSA Series:

Application:

About Us:

Established in China in 2016, Flow Tech represents around 30 leading suppliers and acts as their local sales agent. Products are divided into several business areas enabling the company to combined the advantage of being specialised in small areas with the benefits of being part of a large organisation. Further, with its ability to see the whole value chain and total costs, Flow Tech aims to improve its customers’ competitive advantage and profitability. The company’s ambition is to make life easier for its customers and to find the best and most cost-efficient solutions.

Why Choose Us?

Our Warehouse:

Packing and Delivery:

Packing:

Carton + Wooden Box + Pallet

FAQ:

Q: Which brands are you representing?

A: We are the official appointed agent of THK,HIWIN,PMI,TBI,CPC,CSK, etc.

Q: How about the production time?

A: Generally 3-5 days if we get the stock.

Q: Do you provide samples?

A: Yes, but they are not free of charge.

Q: What is your payment terms?

A: 30% as deposit, and the balance before shipment.

Q: Can you arrange door to door delivery?

A: Sure, we can quote based on DDP, door to door, duty paid. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Vacuum, Magnetically, Low Temperature, Corrosion Resistant, High Temperature, High Speed |

|---|---|

| Function: | Super |

| Flange Shape: | Square |

| Shape: | Straight |

| Series: | LM |

| Material: | Bearing Steel |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do I choose the right block bearing for my machinery?

Choosing the right block bearing for your machinery is crucial to ensure optimal performance, reliability, and longevity. Here’s a detailed explanation of the factors to consider when selecting a block bearing:

- Load Requirements: Determine the load requirements of your machinery, including the magnitude and direction of the loads that will be applied to the bearing. Consider factors such as static loads, dynamic loads, and shock loads. This information will help you choose a block bearing with the appropriate load-carrying capacity and load rating.

- Speed and Operating Conditions: Consider the speed at which your machinery will operate and the corresponding operating conditions. High-speed applications may require block bearings with specific design features, such as lower friction, improved heat dissipation, and higher precision. Additionally, assess the operating environment for factors like temperature, humidity, dust, and chemical exposure, as these can impact the choice of bearing materials and seals.

- Bearing Type and Configuration: Choose the appropriate bearing type and configuration based on your machinery’s requirements. Common types of block bearings include ball bearings, roller bearings, and spherical bearings. Consider factors such as the type of motion, misalignment compensation, and ease of installation when selecting the bearing type.

- Bearing Size and Shaft Diameter: Determine the required bearing size and shaft diameter for your machinery. The bearing should be properly sized to handle the loads and fit securely on the shaft. Refer to manufacturer guidelines or consult engineering resources to determine the appropriate bearing size and shaft diameter for your specific application.

- Sealing and Lubrication: Consider the sealing and lubrication requirements of your machinery. Sealing arrangements help protect the bearing from contaminants and retain lubrication. Choose the appropriate sealing options based on the operating environment and the desired level of protection. Additionally, select the right lubricant and lubrication method based on factors such as operating speed, temperature, and load conditions.

- Industry Standards and Regulations: Ensure that the selected block bearing complies with relevant industry standards and regulations. Compliance with standards such as ISO, ANSI, or ABMA ensures that the bearing meets quality and performance requirements.

- Consult Manufacturer or Supplier: If you are unsure about the appropriate block bearing for your machinery, consult the manufacturer or a reputable supplier. They can provide expert guidance, technical support, and recommend suitable products based on their experience and knowledge.

By considering these factors and seeking expert advice when needed, you can choose the right block bearing that matches the requirements of your machinery, ensuring reliable and efficient operation.

How do block bearings cope with misalignment issues?

Block bearings are designed to cope with misalignment issues to a certain extent. While they are not intended to compensate for significant misalignments, they do possess some inherent features that allow them to accommodate minor misalignments between the shaft and the housing. Here are some ways in which block bearings cope with misalignment:

1. Self-Alignment: Some block bearings, such as self-aligning block bearings, have a spherical outer diameter or a convex spherical surface on the inner ring. This design allows the bearing to self-align to a certain degree, compensating for minor misalignments between the shaft and the housing. Self-aligning block bearings are particularly useful in applications where shaft deflection or misalignment is expected.

2. Floating Design: Block bearings often have a floating design, which means that the bearing insert is not rigidly fixed within the housing. Instead, it is allowed to move slightly within the housing. This floating arrangement helps to accommodate minor misalignments by allowing the bearing to adjust its position and angle slightly, reducing the stress and friction caused by misalignment.

3. Lubrication and Reduced Friction: Adequate lubrication is crucial for block bearings to cope with misalignment. Proper lubrication helps to reduce friction and wear, which can be exacerbated by misalignment. The lubricant forms a thin film between the rolling elements and the raceways, allowing them to roll smoothly and reducing the impact of misalignment on the bearing’s performance.

4. Elastic Deformation: In some cases, the materials used in block bearings, such as the housing or the bearing insert, may have some degree of elasticity. This elastic deformation can help to absorb and accommodate minor misalignments by allowing the bearing components to flex slightly, reducing stress concentrations.

Despite these coping mechanisms, it is important to note that block bearings have limitations when it comes to misalignment. Excessive or severe misalignment can lead to increased friction, accelerated wear, and premature failure of the bearing. Therefore, it is generally recommended to align the shaft and the housing as accurately as possible during installation to minimize misalignment and maximize the performance and lifespan of the block bearing.

Proper installation practices, including the use of alignment tools and following manufacturer guidelines, can help ensure the alignment is within acceptable tolerances. Regular inspection and maintenance should also be performed to detect and address any misalignment issues that may arise over time.

When encountering significant misalignment or when misalignment becomes a recurring problem, it may be necessary to consider alternative solutions such as flexible couplings or other alignment devices to address the underlying causes of misalignment and protect the block bearing from excessive stress and premature failure.

Where can I purchase block bearings?

If you are looking to purchase block bearings, there are several options available to you. Here’s a detailed explanation of where you can purchase block bearings:

- Local Industrial Suppliers: One of the most convenient options is to check with local industrial suppliers or distributors in your area. These suppliers typically carry a wide range of bearings, including block bearings, and can provide you with the necessary guidance and support in selecting the right product for your specific application. You can search online directories or use search engines to find industrial suppliers near you.

- Bearing Manufacturers: Many bearing manufacturers have their own sales channels and online platforms where you can directly purchase block bearings. Some well-known bearing manufacturers include SKF, Timken, NSK, NTN, and FAG. Visiting the manufacturers’ websites will provide you with information on their authorized distributors, online stores, or contact details to inquire about purchasing options.

- Online Marketplaces: Online marketplaces like Amazon, eBay, and Alibaba offer a wide selection of block bearings from various sellers and suppliers. These platforms allow you to compare prices, read customer reviews, and choose from different brands and models. However, it’s important to ensure that you are purchasing from reputable sellers with positive ratings and reviews.

- Specialized Bearing Suppliers: There are specialized bearing suppliers that focus specifically on bearings and related products. These suppliers often have a comprehensive inventory of different types of bearings, including block bearings. They may have online stores or physical locations where you can make a purchase. Searching online for “specialized bearing suppliers” or “bearing distributors” will help you find such suppliers.

- Industrial Trade Shows and Exhibitions: Attending industrial trade shows and exhibitions related to machinery, bearings, or specific industries can provide an opportunity to connect with multiple suppliers and manufacturers in one place. These events often have exhibitors showcasing their products, including block bearings, and you can discuss your requirements directly with the representatives to make a purchase or gather information for future procurement.

- Local Machine Shops: Local machine shops or maintenance and repair service providers may stock block bearings for immediate purchase. These establishments often have a range of bearings available for quick replacement or repair needs. It’s worth checking with local machine shops in your area to inquire about their bearing inventory and purchasing options.

When purchasing block bearings, it’s important to consider factors such as the specific requirements of your application, the load capacity and speed rating of the bearing, the compatibility with your shaft diameter, and the quality and reputation of the supplier or manufacturer. It’s advisable to consult with experts or technical support from the supplier to ensure you select the right bearing for your needs.

Remember to compare prices, check for warranties or guarantees, and consider the shipping or delivery options before making a purchase decision.

editor by CX 2024-05-09

China supplier UCP/Ssucp/UCT Ssuc Bearing with White Color Plastic Block bearing driver kit

Product Description

Company introduction:

This is from GUANXIAN HAGUAN BEARING CO.,LTD.,located in China.WHB is our brand. We specialize in manufacturing double-row spherical roller bearing,pillow block bearing,thrust ball bearing and so on . We could supply bearing for you with competitive price or best price. Our products are sold well to Russia, Brazil, Mexico, Poland and Tunisia ect. If you are interested in our products, please send the enquiry to us as soon as possible. If you have any questions about the bearing can consult me.

Hope to establish a good business relationship with you. Looking forward to your early reply.

Thanks and best regards.

ISO Certificate:

CE Certificate:

Products:

UC204~UC218 UCP/UCF/UCFL/UCT/UCFC

UC304~UC318 UCP/UCF/UCFL/UCT/UCFC

Quality: P0/Full grinding/Super finishing

Technical Parameters:

Package:

Fair Show:

Common Problems:

1. What’s the minimum order quantity of your company?

our minimum order is one.

2. Can you accept OEM and customize it?

Yes, we can customize it for you according to the samples or drawings.

3. Can you provide samples for free?

Yes, we can provide samples free of charge, but we need our customers to bear the freight.

4.Is your company a factory or a trading company?

we have our own factories. We export bearings all over the world.

5. When is the warranty period of your bearings?

within 3 months, the customer needs to provide photos and return the bearing.

6.Can you tell me your company’s payment terms are acceptable?

T / T, D / P, L / C, Western Union remittance,Paypal,Money Gram….

7.Can you tell me the delivery time of your goods?

7-15 days, mainly depending on the quantity of your order. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Non-Aligning Bearing |

|---|---|

| Separated: | Separated |

| Feature: | Vacuum, Magnetically, Low Temperature, High Temperature, High Speed |

| Rows Number: | Single |

| Raceway: | Crowned Raceway |

| Bearing Block Model: | P |

| Samples: |

US$ 2.5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What is the typical price range for block bearings?

The price range for block bearings can vary depending on various factors such as the bearing type, size, materials, quality, and the supplier or manufacturer. Here’s a detailed explanation of the typical price range for block bearings:

1. Standard Block Bearings: Standard block bearings, commonly used in many industrial applications, are generally more affordable compared to specialized or high-performance variants. The price range for standard block bearings typically varies from a few dollars to several tens of dollars per bearing, depending on factors such as the bearing size, load capacity, and quality of construction.

2. Specialized Block Bearings: Specialized block bearings designed for specific applications or industries may have a higher price range due to their unique features, materials, or performance characteristics. For example, block bearings designed for high-speed applications, extreme temperatures, or corrosive environments may fall into a higher price range. Prices for specialized block bearings can range from tens of dollars to several hundred dollars per bearing, depending on the specific requirements and performance specifications.

3. High-Precision or Custom Block Bearings: High-precision block bearings or custom-designed bearings, which are manufactured to very tight tolerances or tailored to specific machinery requirements, can have a higher price range. These bearings often involve additional engineering, manufacturing, or quality control processes, which contribute to their higher cost. The price range for high-precision or custom block bearings can vary significantly, ranging from hundreds of dollars to several thousand dollars per bearing.

It’s important to note that the prices mentioned above are general estimates and can vary based on factors such as geographical location, market demand, quantity ordered, and supplier-specific pricing policies. Additionally, prices may also be subject to fluctuations over time due to factors such as raw material costs, manufacturing expenses, and market conditions.

When considering the price of block bearings, it’s essential to balance cost with quality and performance requirements. Opting for reputable suppliers or manufacturers known for their reliability and product quality is advisable to ensure that the block bearings meet the desired specifications and provide long-term value.

What is the lifespan of a block bearing?

The lifespan of a block bearing can vary depending on several factors, including the operating conditions, the type of bearing, the quality of the bearing and its components, and the level of maintenance and lubrication. It is challenging to provide an exact lifespan for a block bearing as it can be influenced by these variables. However, with proper installation, maintenance, and operating conditions, block bearings can have a long service life.

The manufacturer of the block bearing typically provides an estimated service life or a rating for the bearing under specific conditions. This rating is often referred to as the L10 life or the basic rating life. The L10 life represents the number of hours that 90% of a group of identical bearings are expected to operate before the onset of fatigue failure. It is important to note that the L10 life is a statistical calculation based on standardized testing and assumptions about operating conditions. Actual bearing life can vary significantly depending on the application.

Several factors can influence the lifespan of a block bearing:

- Operating Conditions: The operating conditions, including the load magnitude and direction, speed, and temperature, can significantly impact the lifespan of a block bearing. Higher loads, excessive speeds, and extreme temperatures can accelerate wear and fatigue, reducing the bearing’s lifespan.

- Maintenance and Lubrication: Regular maintenance practices, including proper lubrication, can help extend the lifespan of a block bearing. Inadequate or improper lubrication can lead to increased friction, wear, and premature failure. Regular inspection, cleaning, and re-lubrication according to the manufacturer’s recommendations are essential for optimal bearing performance and longevity.

- Quality and Design: The quality of the block bearing and its components, as well as the design and manufacturing standards, can impact its lifespan. High-quality bearings manufactured by reputable companies tend to have more consistent performance and longer lifespans compared to lower-quality alternatives.

- Application-Specific Factors: Certain applications may expose block bearings to harsh or demanding conditions, such as heavy loads, high vibrations, or corrosive environments. These factors can affect the bearing’s lifespan and may require special considerations in terms of bearing selection, materials, and maintenance.

It is important to monitor the condition of block bearings regularly and be vigilant for any signs of wear, damage, or decreased performance. By addressing issues promptly, performing routine maintenance, and following proper operating practices, it is possible to maximize the lifespan of block bearings and ensure reliable operation of the machinery.

Ultimately, the lifespan of a block bearing can vary, and it is recommended to consult the manufacturer’s guidelines and work with qualified engineers or technicians to determine the expected lifespan in specific operating conditions.

Where can I purchase block bearings?

If you are looking to purchase block bearings, there are several options available to you. Here’s a detailed explanation of where you can purchase block bearings:

- Local Industrial Suppliers: One of the most convenient options is to check with local industrial suppliers or distributors in your area. These suppliers typically carry a wide range of bearings, including block bearings, and can provide you with the necessary guidance and support in selecting the right product for your specific application. You can search online directories or use search engines to find industrial suppliers near you.

- Bearing Manufacturers: Many bearing manufacturers have their own sales channels and online platforms where you can directly purchase block bearings. Some well-known bearing manufacturers include SKF, Timken, NSK, NTN, and FAG. Visiting the manufacturers’ websites will provide you with information on their authorized distributors, online stores, or contact details to inquire about purchasing options.

- Online Marketplaces: Online marketplaces like Amazon, eBay, and Alibaba offer a wide selection of block bearings from various sellers and suppliers. These platforms allow you to compare prices, read customer reviews, and choose from different brands and models. However, it’s important to ensure that you are purchasing from reputable sellers with positive ratings and reviews.

- Specialized Bearing Suppliers: There are specialized bearing suppliers that focus specifically on bearings and related products. These suppliers often have a comprehensive inventory of different types of bearings, including block bearings. They may have online stores or physical locations where you can make a purchase. Searching online for “specialized bearing suppliers” or “bearing distributors” will help you find such suppliers.

- Industrial Trade Shows and Exhibitions: Attending industrial trade shows and exhibitions related to machinery, bearings, or specific industries can provide an opportunity to connect with multiple suppliers and manufacturers in one place. These events often have exhibitors showcasing their products, including block bearings, and you can discuss your requirements directly with the representatives to make a purchase or gather information for future procurement.

- Local Machine Shops: Local machine shops or maintenance and repair service providers may stock block bearings for immediate purchase. These establishments often have a range of bearings available for quick replacement or repair needs. It’s worth checking with local machine shops in your area to inquire about their bearing inventory and purchasing options.

When purchasing block bearings, it’s important to consider factors such as the specific requirements of your application, the load capacity and speed rating of the bearing, the compatibility with your shaft diameter, and the quality and reputation of the supplier or manufacturer. It’s advisable to consult with experts or technical support from the supplier to ensure you select the right bearing for your needs.

Remember to compare prices, check for warranties or guarantees, and consider the shipping or delivery options before making a purchase decision.

editor by CX 2024-05-08

China Professional Original CZPT Shs20V Shs20LV Linear Guide Slide Bearing Shs 20V 20LV Lm Linear Motion Guide Block Bearing supplier

Product Description

Japan THK LM Block / Carriage / Rail / Linear Xihu (West Lake) Dis.

| Procuct Name | Japan Original THK LM Xihu (West Lake) Dis. |

| Material | Chrome Steel/ Stainless Steel |

| Brand Name | THK |

| Features | High speed, energy saving |

SHS Series:

SHS15C SHS15R SHS15V SHS20C SHS20V SHS25C SHS25R SHS25V SHS30C

SHS30R SHS30V SHS35C SHS35R SHS35V SHS45C SHS45R SHS45V SHS55C

SHS55R SHS55V SHS65C SHS65V SHS15LC SHS15LR SHS15LV SHS20LC SHS20LV

SHS25LC SHS25LR SHS25LV SHS30LC SHS30LR SHS30LV SHS35LC SHS35LR SHS35LV

SHS45LC SHS45LR SHS45LV SHS55LC SHS55LR SHS55LV SHS65LC SHS65LV

SHS15C1SS SHS15R1SS SHS15V1SS SHS20C1SS

SHS20V1SS SHS25C1SS SHS25R1SS SHS25V1SS

SHS30C1SS SHS30R1SS SHS30V1SS SHS35C1SS

SHS35R1SS SHS35V1SS SHS45C1SS SHS45R1SS

SHS45V1SS SHS55C1SS SHS55R1SS SHS55V1SS

SHS65C1SS SHS65V1SS SHS15LC1SS SHS15LR1SS

SHS15LV1SS SHS20LC1SS SHS20LV1SS SHS25LC1SS

SHS25LR1SS SHS25LV1SS SHS30LC1SS SHS30LR1SS

SHS30LV1SS SHS35LC1SS SHS35LR1SS SHS35LV1SS

SHS45LC1SS SHS45LR1SS SHS45LV1SS SHS55LC1SS

SHS55LR1SS SHS55LV1SS SHS65LC1SS SHS65LV1SS

Application:

About Us:

Established in China in 2016, Flow Tech represents around 30 leading suppliers and acts as their local sales agent. Products are divided into several business areas enabling the company to combined the advantage of being specialised in small areas with the benefits of being part of a large organisation. Further, with its ability to see the whole value chain and total costs, Flow Tech aims to improve its customers’ competitive advantage and profitability. The company’s ambition is to make life easier for its customers and to find the best and most cost-efficient solutions.

Why Choose Us?

Our Warehouse:

Packing and Delivery:

Packing:

Carton + Wooden Box + Pallet

FAQ:

Q: Which brands are you representing?

A: We are the official appointed agent of THK,HIWIN,PMI,TBI,CPC,CSK, etc.

Q: How about the production time?

A: Generally 3-5 days if we get the stock.

Q: Do you provide samples?

A: Yes, but they are not free of charge.

Q: What is your payment terms?

A: 30% as deposit, and the balance before shipment.

Q: Can you arrange door to door delivery?

A: Sure, we can quote based on DDP, door to door, duty paid. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Vacuum, Magnetically, Low Temperature, Corrosion Resistant, High Temperature, High Speed |

|---|---|

| Function: | Super |

| Flange Shape: | Square |

| Shape: | Straight |

| Series: | LM |

| Material: | Bearing Steel |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do I replace a block bearing?

Replacing a block bearing involves a series of steps to ensure proper removal of the old bearing and installation of the new one. Here’s a detailed explanation of the process for replacing a block bearing:

- Gather the Required Tools: Before starting the replacement process, gather all the necessary tools and equipment. This may include wrenches, sockets, a puller or press (if needed), lubricants, cleaning materials, and safety gear such as gloves and goggles.

- Prepare the Work Area: Clear the area around the machinery and ensure a clean and safe workspace. This will make it easier to access the bearing and perform the replacement without any obstructions.

- Disconnect Power and Lockout/Tagout: If the machinery is powered, disconnect the power supply and follow appropriate lockout/tagout procedures to ensure the equipment cannot be accidentally started while you are working on it. This step is crucial for your safety.

- Remove External Components: If there are any external components or accessories attached to the block bearing, such as seals, covers, or locking devices, remove them using the appropriate tools.

- Secure the Shaft: Depending on the design of the machinery, you may need to secure the shaft to prevent it from rotating during the bearing removal process. This can be done using shaft clamps or other suitable methods.

- Remove the Old Bearing: Use the appropriate tools to remove the old bearing from the housing. This may involve loosening locking devices, such as set screws or eccentric collars if present, and applying force evenly to remove the bearing from the shaft.

- Clean and Inspect: Once the old bearing is removed, thoroughly clean the housing, shaft, and surrounding components. Inspect them for any signs of damage or wear that may need to be addressed before installing the new bearing.

- Apply Lubrication: Apply the appropriate lubrication to the housing, shaft, and the new bearing. Refer to the manufacturer’s guidelines for the recommended lubricant type and amount.

- Install the New Bearing: Carefully install the new bearing into the housing, ensuring it is properly aligned and seated. Use the appropriate tools or techniques to secure the bearing in place according to the manufacturer’s instructions. This may include tightening set screws, applying locking devices, or using press-fit methods if necessary.

- Reattach External Components: Once the new bearing is properly installed, reattach any external components or accessories that were removed earlier, such as seals or covers.

- Perform Functionality Checks: Before restoring power or resuming operation, perform functionality checks to ensure the new bearing is functioning correctly. Rotate the shaft manually to verify smooth operation, check for any abnormal noises or vibrations, and confirm that the bearing is properly secured.

- Restore Power and Test: If everything checks out, restore power to the machinery and conduct thorough testing to ensure the replacement bearing is operating as expected. Monitor the machinery closely during the initial period of operation to ensure there are no issues.

It’s important to note that the above steps provide a general guideline for replacing a block bearing. The specific process may vary depending on the machinery design, manufacturer guidelines, and any unique considerations related to the application. Always refer to the manufacturer’s instructions and follow proper safety protocols when performing any maintenance or replacement tasks.

Can block bearings handle both radial and axial loads?

Yes, block bearings are designed to handle both radial and axial loads. Block bearings, also known as pillow block bearings or plummer block bearings, are a type of bearing housing that contains a rolling element bearing. These bearings are commonly used in various industrial applications to support rotating shafts and provide support for both radial and axial loads.

The design of block bearings allows them to accommodate radial loads, which are forces acting perpendicular to the shaft’s axis. Radial loads can be caused by the weight of the shaft, the load being transmitted through the shaft, or other external forces acting on the bearing.

In addition to radial loads, block bearings are also capable of handling axial loads, which are forces acting parallel to the shaft’s axis. Axial loads can be caused by thrust or pushing/pulling forces exerted on the bearing. The ability of block bearings to handle axial loads depends on their specific design and configuration.

Block bearings typically consist of a housing (block) and an insert bearing. The housing provides support and protection for the bearing, while the insert bearing is the rolling element bearing that carries the load. The insert bearing can be designed to handle both radial and axial loads, depending on its type and construction.

Some block bearings use deep groove ball bearings as the insert bearing, which are capable of handling both radial and axial loads. Other types of insert bearings, such as spherical roller bearings or tapered roller bearings, are specifically designed to handle higher axial loads in addition to radial loads.

It’s important to consider the specific application requirements and load conditions when selecting block bearings. The manufacturer’s specifications and guidelines should be consulted to ensure that the chosen block bearings are suitable for the expected radial and axial load capacities.

Overall, block bearings are designed to provide support for both radial and axial loads, making them versatile and widely used in various machinery and equipment applications.

What are the standard dimensions for block bearings?

The dimensions of block bearings, also known as pillow block bearings, can vary depending on the specific design and manufacturer. However, there are standard dimensions that are commonly used in the industry. Here’s a detailed explanation of the standard dimensions for block bearings:

Block bearings consist of a bearing insert (also called an inner ring) and a housing (also called an outer ring or pillow block). The housing is typically a solid or split housing with mounting holes for attachment to a support structure. The bearing insert is designed to fit inside the housing and supports the rotating shaft. The dimensions of block bearings are typically specified using the following parameters:

- Shaft Diameter (d): This refers to the diameter of the shaft that will be inserted into the bearing. The standard shaft diameters for block bearings range from a few millimeters up to several inches, depending on the application requirements. Common shaft diameter sizes include 1/2″, 5/8″, 3/4″, 1″, 1-1/4″, 1-1/2″, and 2″.

- Housing Length (L): The housing length refers to the distance between the mounting surfaces of the housing. It determines the overall length of the block bearing assembly. The housing length can vary depending on the bearing size and design, but common lengths range from around 2 inches to several inches or more.

- Housing Width (B): The housing width refers to the width of the housing, perpendicular to the shaft. It determines the overall width of the block bearing assembly. The housing width can vary depending on the bearing size and design, but common widths range from around 1 inch to several inches or more.

- Mounting Hole Spacing (Bolt Hole Centers): Block bearings typically have multiple mounting holes for attachment to the support structure. The mounting hole spacing refers to the distance between the centers of these mounting holes. The standard mounting hole spacing is often specified using a bolt hole center-to-center distance, such as 2-bolt, 3-bolt, or 4-bolt configurations. The specific dimensions can vary depending on the bearing size and design.

- Bearing Insert Width (Bearing Width): The bearing insert width refers to the width of the bearing insert itself. It determines the amount of support and contact area for the rotating shaft. The bearing insert width can vary depending on the bearing size and design, but common widths range from around 0.5 inch to several inches or more.

It’s important to note that these are general standard dimensions, and variations may exist depending on the specific manufacturer and bearing type. Additionally, some block bearings may have additional features or variations in dimensions to cater to specific applications or industry requirements.

When selecting a block bearing, it’s crucial to consider the specific dimensions required for your application, including the shaft diameter, housing length and width, and mounting hole spacing. Consulting the manufacturer’s specifications and guidelines is recommended to ensure the correct dimensions are chosen for your specific needs.

editor by CX 2024-05-07

China supplier Pedestal Bearing/Conveying Equipment Bearing/Block Bearing (UCF200 UCF300) bearing driver kit

Product Description

1.(1)ZheJiang CZPT Bearing Manufacture Co., ltd, is the professional manufacture and exporter of Pillow block bearing, make the bearing and housing all by ourselves.

(2)20 years’ expeience of producing and exporting all kinds of bearings.

(3)With the advanced technique and equipments, we can provide high-level products under standard process and device .

(4)We have passed the ISO9001:2000 International Quality Management System and got the Certificate of Import & Export from our government .

(5)The annual output is more than 10 million sets

Product Description:

Pillow blocks consist of the insert ball bearing and housing.

Insert ball bearing are designed in almost the same way as deep groove ball

bearing, except the outer ring is spherical and the inner ring is wide.

Application:

Agricultural machinery, construction equipment, conveyor systems, textile machines and mining machines etc.

Specification

| Brand | FKD HHB or OEM |

| Structure | Pillow Block Bearing |

| Model Number | Any |

| Bearing Material | Chrome Steel, Stainless Steel, Plastic |

| Cage Material | Steel |

| Seals | Normal Seal, Triple Seal , F seal or as requirement |

| Lubrication | Grease, Oil |

| Precision | ABEC-1 (P0) |

| Clearance | C1, C2, C0, C3, C4, C5 |

| Vibration | V1, V2, V3, V4 |

| Noise | Z1, Z2, Z3, Z4 |

| Service | OEM |

| Place of Origin | ZheJiang , China(Mainland) |

| Sample | Free Sample |

| Port | HangZhou or as requirement |

Data information

| Bearing No. |

Dimensions mm inch |

Bolt Size mm inch |

|||||||||

| d | a | e | i | g | l | s | z | B | n | ||

| UCF201 | 12 | 86 | 64 | 15 | 12 | 25.5 | 12 | 33.3 | 31 | 12.7 | M10 |

| UCF201-8 | 1/2 | 3-3/8 | 2-33/64 | 19/32 | 15/32 | 1 | 15/32 | 1-5/16 | 1.2205 | 0.5 | 3/8 |

| UCF202 | 15 | 86 | 64 | 15 | 12 | 25.5 | 12 | 33.3 | 31 | 12.7 | M10 |

| UCF202-9 | 9/16 | 3-3/8 | 2-33/64 | 19/32 | 15/32 | 1 | 15/32 | 1-5/16 | 1.2205 | 0.5 | 3/8 |

| UCF202-10 | 5/8 | ||||||||||

| UCF203 | 17 | 86 | 64 | 15 | 12 | 25.5 | 12 | 33.3 | 31 | 12.7 | M10 |

| UCF203-11 | 11/16 | 3-3/8 | 2-33/64 | 19/32 | 15/32 | 1 | 15/32 | 1-5/16 | 1.2205 | 0.5 | 3/8 |

| UCF204 | 20 | 86 | 64 | 15 | 12 | 25.5 | 12 | 33.3 | 31 | 12.7 | M10 |

| UCF204-12 | 3/4 | 3-3/8 | 2-33/64 | 19/32 | 15/32 | 1 | 15/32 | 1-5/16 | 1.2205 | 0.5 | 3/8 |

| UCF205 | 25 | 95 | 70 | 16 | 14 | 27 | 12 | 35.8 | 34.1 | 14.3 | M10 |

| UCF205-13 | 13/16 | 3-3/4 | 2-3/4 | 5/8 | 35/64 | 1-1/16 | 15/32 | 1-13/32 | 1.3425 | 0.563 | 3/8 |

| UCF205-14 | 7/8 | ||||||||||

| UCF205-15 | 15/16 | ||||||||||

| UCF205-16 | 1 | ||||||||||

| UCF206 | 30 | 108 | 83 | 18 | 14 | 31 | 12 | 40.2 | 38.1 | 15.9 | M14 |

| UCF206-17 | 1-1/16 | 4-1/4 | 3-17/64 | 45/64 | 35/64 | 1-7/32 | 15/32 | 1-19/32 | 1.5 | 0.626 | 1/2 |

| UCF206-18 | 1-1/8 | ||||||||||

| UCF206-19 | 1-3/16 | ||||||||||

| UCF206-20 | 1-1/4 | ||||||||||

| UCF207 | 35 | 117 | 92 | 19 | 16 | 34 | 14 | 44.4 | 42.9 | 17.5 | M14 |

| UCF207-20 | 1-1/4 | 4-39/64 | 3-5/8 | 3/4 | 5/8 | 1-11/32 | 35/64 | 1-3/4 | 1.689 | 0.689 | 1/2 |

| UCF207-21 | 1-5/16 | ||||||||||

| UCF207-22 | 1-3/8 | ||||||||||

| UCF207-23 | 1-7/16 | ||||||||||

| UCF208 | 40 | 130 | 102 | 21 | 16 | 36 | 16 | 51.2 | 49.2 | 19 | M14 |

| UCF208-24 | 1-1/2 | 5-1/8 | 4-1/64 | 53/64 | 5/8 | 1-27/64 | 5/8 | 2-1/64 | 1.937 | 0.748 | 1/2 |

| UCF208-25 | 1-9/6 | ||||||||||

| UCF209 | 45 | 137 | 105 | 22 | 18 | 38 | 16 | 52.2 | 49.2 | 19 | M14 |

| UCF209-26 | 1-5/8 | 5-13/32 | 4-9/64 | 55/64 | 23/32 | 1-1/2 | 5/8 | 2-1/64 | 1.937 | 0.748 | 1/2 |

| UCF209-27 | 1-11/16 | ||||||||||

| UCF209-28 | 1-3/4 | ||||||||||

| UCF210 | 50 | 143 | 111 | 22 | 18 | 40 | 16 | 54.6 | 51.6 | 19 | M16 |

| UCF210-29 | 1-13/16 | 5-5/8 | 4-3/8 | 55/64 | 23/32 | 1-9/16 | 5/8 | 2-5/32 | 2.571 | 0.748 | 5/8 |

| UCF210-30 | 1-7/8 | ||||||||||

| UCF210-31 | 1-15/16 | ||||||||||

| UCF210-32 | 2 | ||||||||||

| UCF211 | 55 | 162 | 130 | 25 | 20 | 43 | 19 | 58.4 | 55.6 | 22.2 | M16 |

| UCF211-32 | 2 | 6-3/8 | 5-1/8 | 63/64 | 25/32 | 1-11/16 | 3/4 | 1-5/16 | 2.189 | 0.874 | 5/8 |

| UCF211-33 | 2-1/16 | ||||||||||

| UCF211-34 | 2-1/8 | ||||||||||

| UCF211-35 | 2-3/16 | ||||||||||

| UCF212 | 60 | 175 | 143 | 29 | 20 | 48 | 19 | 68.7 | 65.1 | 25.4 | M16 |

| UCF212-36 | 2-1/4 | 6-57/64 | 5-5/8 | 1-3/16 | 25/32 | 1-57/64 | 3/4 | 2-45/64 | 2.563 | 1 | 5/8 |

| UCF212-37 | 2-5/16 | ||||||||||

| UCF212-38 | 2-3/8 | ||||||||||

| UCF212-39 | 2-7/16 | ||||||||||

| UCF213 | 65 | 187 | 149 | 30 | 22 | 50 | 19 | 69.7 | 65.1 | 25.4 | M20 |

| UCF213-40 | 2-1/2 | 7-23/64 | 5-55/64 | 36966 | 55/64 | 1-31/32 | 3/4 | 2.563 | 1 | ||

| UCF213-41 | 2-9/16 | ||||||||||

| UCF214 | 70 | 193 | 152 | 31 | 22 | 54 | 19 | 75.4 | 74.6 | 30.2 | M20 |

| UCF214-42 | 2-5/8 | 7-19/32 | 5-63/64 | 1-7/32 | 55/64 | 2-1/8 | 3/4 | 2-31/32 | 2.937 | 1.189 | 3/4 |

| UCF214-43 | 2-11/16 | ||||||||||

| UCF214-44 | 2-3/4 | ||||||||||

| UCF215 | 75 | 200 | 159 | 34 | 22 | 56 | 19 | 78.5 | 77.8 | 33.3 | M20 |

| UCF215-45 | 2-13/16 | 7-7/8 | 6-17/64 | 1-11/32 | 55/64 | 2-7/32 | 3/4 | 3-3/32 | 3.063 | 1.311 | 3/4 |

| UCF215-46 | 2-7/8 | ||||||||||

| UCF215-47 | 2-15/16 | ||||||||||

| UCF215-48 | 3 | ||||||||||

| UCF216 | 80 | 208 | 165 | 34 | 22 | 58 | 23 | 83.3 | 82.6 | 65.1 | M20 |

| UCF216-49 | 3-1/16 | 8-3/16 | 6-1/2 | 1-11/32 | 55/64 | 2-9/32 | 29/32 | 3-9/323 | 3.252 | 2.563 | 3/4 |

| UCF216-50 | 3-1/8 | ||||||||||

| UCF216-51 | 3-3/16 | ||||||||||

| UCF217 | 85 | 220 | 175 | 36 | 24 | 63 | 23 | 87.6 | 85.7 | 34.1 | M20 |

| UCF217-52 | 3-1/14 | 8-21/23 | 6-57/64 | 1-27/64 | 15/16 | 2-15/32 | 29/32 | 3-71/16 | 3.374 | 1.343 | 3/4 |

| UCF217-53 | 3-5/16 | ||||||||||

| UCF217-55 | 3-7/16 | ||||||||||

| UCF218 | 90 | 235 | 187 | 40 | 24 | 68 | 23 | 96.3 | 96 | 39.7 | M20 |

| UCF218-56 | 3-1/2 | 9-1/4 | 7-23/64 | 1-37/64 | 15/16 | 2-11/16 | 29/32 | 3-25/32 | 3.7795 | 1.563 | 3/4 |

| UCF305 | 25 | 110 | 80 | 16 | 13 | 29 | 16 | 39 | 38 | 15 | M14 |

| UCF305-13 | 13/16 | 4-11/32 | 3-5/32 | 5/8 | 1/ 2 | 1-5/32 | 5/8 | 1-17/32 | 1.4961 | 0.591 | 1/ 2 |

| UCF305-14 | 7/8 | ||||||||||

| UCF305-15 | 15/16 | ||||||||||

| UCF305-16 | 1 | ||||||||||

| UCF306 | 30 | 125 | 95 | 18 | 15 | 32 | 16 | 44 | 43 | 17 | M14 |

| UCF306-17 | 1-1/16 | 4-29/32 | 3-37/64 | 45/64 | 19/32 | 1-1/4 | 5/8 | 1-47/64 | 1.6929 | 0.669 | 1/ 2 |

| UCF306-18 | 1-1/8 | ||||||||||

| UCF306-19 | 1-3/16 | ||||||||||

| UCF307 | 35 | 135 | 100 | 20 | 16 | 36 | 19 | 49 | 48 | 19 | M16 |

| UCF307-20 | 1-1/4 | 5-5/16 | 3-15/16 | 25/32 | 5/8 | 1-13/32 | 3/ 4 | 1-59/64 | 1.8898 | 0.748 | 5/8 |

| UCF307-21 | 1-5/16 | ||||||||||

| UCF307-22 | 1-3/8 | ||||||||||

| UCF307-23 | 1-7/16 | ||||||||||

| UCF308 | 40 | 150 | 112 | 23 | 17 | 40 | 19 | 56 | 52 | 19 | M16 |

| UCF308-24 | 1-1/2 | 5-29/32 | 4-13/32 | 29/32 | 21/32 | 1-9/16 | 3/ 4 | 2-13/64 | 2.571 | 0.748 | 5/8 |

| UCF308-25 | 1-9/16 | ||||||||||

| UCF309 | 45 | 160 | 125 | 25 | 18 | 44 | 19 | 60 | 57 | 22 | M16 |

| UCF309-26 | 1-5/8 | 6-5/16 | 4-59/64 | 63/64 | 23/32 | 1-23/32 | 3/ 4 | 2-23/64 | 2.2441 | 0.866 | 5/8 |

| UCF309-27 | 1-11/16 | ||||||||||

| UCF309-28 | 1-3/4 | ||||||||||

| UCF310 | 50 | 175 | 132 | 28 | 19 | 48 | 23 | 67 | 61 | 22 | M20 |

| UCF310-29 | 1-13/16 | 6-7/8 | 5-13/64 | 1-7/64 | 3/ 4 | 1-7/8 | 29/32 | 2-41/64 | 2.4016 | 0.866 | 3/ 4 |

| UCF310-30 | 1-7/8 | ||||||||||

| UCF310-31 | 1-15/16 | ||||||||||

| UCF311 | 55 | 185 | 140 | 30 | 20 | 52 | 23 | 71 | 66 | 25 | M20 |

| UCF311-32 | 2 | 7-9/32 | 5-33/64 | 1-3/16 | 25/32 | 2-1/16 | 29/32 | 2-51/64 | 2.5984 | 0.948 | 3/ 4 |

| UCF311-33 | 2-1/16 | ||||||||||

| UCF311-34 | 2-1/8 | ||||||||||

| UCF311-35 | 2-3/16 | ||||||||||

| UCF312 | 60 | 195 | 150 | 33 | 22 | 56 | 23 | 78 | 71 | 26 | M20 |

| UCF312-36 | 2-1/4 | 7-11/16 | 5-29/32 | 1-19/64 | 7/8 | 2-7/32 | 29/32 | 3-5/64 | 2.7953 | 1.571 | 3/ 4 |

| UCF312-37 | 2-5/16 | ||||||||||

| UCF312-38 | 2-3/8 | ||||||||||

| UCF312-39 | 2-7/16 | ||||||||||

| UCF313 | 65 | 208 | 166 | 33 | 22 | 58 | 23 | 78 | 75 | 30 | M20 |

| UCF313-40 | 2-1/2 | 8-3/16 | 6-17/32 | 1-19/64 | 55/64 | 2-9/32 | 29/32 | 3-5/64 | 2.9528 | 1.818 | 3/ 4 |

| UCF313-41 | 2-9/16 | ||||||||||

| UCF314 | 70 | 226 | 178 | 36 | 25 | 61 | 25 | 81 | 78 | 33 | M22 |

| UCF314-42 | 2-5/8 | 8-29/32 | 6-1/64 | 1-27/64 | 31/32 | 2-13/32 | 63/64 | 3-3/16 | 3.0708 | 1.299 | 7/8 |

| UCF314-43 | 2-11/16 | ||||||||||

| UCF314-44 | 2-3/4 | ||||||||||

| UCF315 | 75 | 236 | 184 | 39 | 25 | 66 | 25 | 89 | 82 | 32 | M22 |

| UCF315-45 | 2-13/16 | 9-19/32 | 7-1/4 | 1-17/32 | 31/32 | 2-19/32 | 63/64 | 3-1/2 | 3.2283 | 1.26 | 7/8 |

| UCF315-46 | 2-7/8 | ||||||||||

| UCF315-47 | 2-15/16 | ||||||||||

| UCF315-48 | 3 | ||||||||||

| UCF316 | 80 | 250 | 196 | 38 | 27 | 68 | 31 | 90 | 86 | 34 | M27 |

| UCF316-49 | 3-1/16 | 9-27/32 | 7-23/32 | 1-1/2 | 1-1/16 | 2-11/16 | 1-7/32 | 3-35/64 | 3.3858 | 1.339 | 1 |

| UCF316-50 | 3-1/8 | ||||||||||

| UCF316-51 | 3-3/16 | ||||||||||

| UCF317 | 85 | 260 | 204 | 44 | 27 | 74 | 31 | 100 | 96 | 40 | M27 |

| UCF317-52 | 3-1/4 | 10-1/4 | 8-1/32 | 1-47/64 | 1-1/16 | 2-29/32 | 1-7/32 | 3-15/16 | 3.7795 | 1.575 | 1 |

| UCF317-53 | 3-5/16 | ||||||||||

| UCF317-55 | 3-7/16 | ||||||||||

| UCF318 | 90 | 280 | 216 | 44 | 30 | 76 | 35 | 100 | 96 | 40 | M27 |

| UCF318-55 | 3-7/16 | 11-1/32 | 8-1/2 | 1-47/64 | 1-3/16 | 3 | 1-3/8 | 3-15/16 | 3.7795 | 1.575 | 1 |

| UCF318-56 | 3-1/2 | ||||||||||

| UCF319 | 95 | 290 | 228 | 59 | 30 | 94 | 35 | 121 | 103 | 41 | M30 |

| UCF319-58 | 3-5/8 | 11-13/32 | 8-31/32 | 2-21/64 | 1-3/16 | 3-11/16 | 1-3/8 | 4-49/64 | 4.571 | 1.614 | 1-1/8 |

| UCF319-59 | 3-11/16 | ||||||||||

| UCF319-60 | 3-3/4 | ||||||||||

| UCF320 | 100 | 310 | 242 | 59 | 32 | 94 | 38 | 125 | 108 | 42 | M33 |

| UCF320-64 | 4 | 12-7/32 | 9-17/32 | 2-21/64 | 1-1/4 | 3-11/16 | 1-1/2 | 3-11/16 | 1-1/2 | 4-29/32 | 1-1/4 |

Trade Term

| Packaging : |

1. Commercial Packaging: Plastic Bag + Color box + Carton + Pallet; 2. Industrial Packaging 3. According to Customer’s Requirements. |

| Delivery: | 2 days for products in stock, 10-20 days for 20″ container |

| Payment : | (1) L/C at sight. (2) 30% T/T in advance, the balance 70% against copy of B/L(CIF) (3) 30% T/T in advance, the balance to be paid off before shipment.(FOB) |

Bearing Characteristics :

| 1 | Thse bearings have a compact design and are easy to mount and dismount |

| 2 | With certain self-aligning effect |

| 3 | Large load capacity |

| 4 | Long service life |

| 5 | Low friction; low vibration and low noise |

Advantage:

(1) We are bearing manufacturers,provide you with all kinds of ball and roller bearings

(2) 20 years’ export experience

(3) Competitive prices

(4) Free sample

(5) High quality and high precision

(6) Good service(OEM ,Modle desigm)

The variety of the bearings we supply in long term:

| 1 | Pillow Block (Bearing Housing); |

| 2 | Deep Groove Ball Bearings; |

| 3 | Tapered Roller Bearings; |

| 4 | Thrust Ball Bearings; |

| 5 | Agriculture bearing |

| 6 | Self-aligning Ball Bearings; |

| 7 | Angular Contact Ball Bearings; |

| 8 | Insert Bearings (Spherical Outer Surface Ball Bearings); |

FAQ

(1) How to prolong service life of bearings?

Accurate installation and using,alignment,timely monitor,re lubrication etc.

(2) Reason for bearings failure?

Usually is incorrect using method,pollution,improper use of lubricant,damage happened in installation and handing,also including installation error.according to the traces can know the reason why is failure

(3) How to choose bearings?

Analyse mechanical device and use conditions.clear the requiremment of bearings.select type of bearings,select distribution way of bearings.selet dimensions of bearings,select installation method of bearing

(4) When select bearings specifications,what you need to consider?

The precision of the bearings(rotating precision,dimensional tolerances)internal clearance and preload bearing material and heat treatment.structure of cage and material.

Contact

Miss Eva

Sales department

ZheJiang CZPT bearing manufacture co ltd

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Aligning Bearing |

|---|---|

| Separated: | Separated |

| Feature: | Vacuum, Magnetically |

| Rows Number: | Double |

| Raceway: | Deep Groove Raceway |

| Material: | Bearing Steel |

| Samples: |

US$ 2.2/Piece

1 Piece(Min.Order) | |

|---|