Product Description

PRODUCT DESCRIPTION

Advantages and Features of Linear Xihu (West Lake) Dis.ways

Δ High positional accuracy

Δ Long life with high motion accuracy

Δ High speed motion is possible with a low driving force

Δ Equal loading capacity in all directions

Δ Easy installation

Δ Easy lubrication

Δ Interchangeability

DOMESTIC XIHU (WEST LAKE) DIS.(Interchange Brand Xihu (West Lake) Dis.)

THK: SHS, SSR, SHW, SRS, SCR, EPF, HSR, SR, HRW, HR, GSR/GSR-R, GSR Series

HIWIN: HG, WE, RG, MGN, QH, QE, PG, CG Series

CPC: MR, ST Series

CSK: LMG, END-M, CS Series

PMI: HG, EG, MGN/MGW Series

TBR: TM, TR Series

TBI, REXROTH, IKO, etc

HIWIN

HGH15CA HGW15CA HGL15CA EGH15SA EGW15SA CGH15CA CGW15CA MGN5C MGW5C

HGH20CA HGW20CA HGL25CA EGH15CA EGW15CA CGH15HA CGW15HA MGN7C MGW7C

HGH20HA HGW20HA HGL25HA EGH20SA EGW20SA CGH20CA CGW20CA MGN7H MGW7H

HGH25CA HGW25CA HGL30CA EGH20CA EGW20CA CGH20HA CGW20HA MGN9C MGW9C

HGH25HA HGW25HA HGL30HA EGH25SA EGW25SA CGH25CA CGW25CA MGN9H MGW9H

HGH30CA HGW30CA HGL35CA EGH25CA EGW25CA CGH25HA CGW25HA MGN12C MGW12C

HGH30HA HGW30HA HGL35HA EGH30SA EGW30SA CGH30CA CGW30CA MGN12H MGW12H

HGH35CA HGW35CA HGL45CA EGH30CA EGW30CA CGH30HA CGW30HA MGN15C MGW15C

HGH35HA HGW35HA HGL45HA EGH35SA EGW35SA CGH35CA CGW35CA MGN15H MGW15H

HGH45CA HGW45CA HGL55CA EGH35CA EGW35CA CGH35HA CGW35HA HGH45HA HGW45HA HGL55HA CGH45CA CGW45CA HGH55CA HGW55CA CGH45HA CGW45HA HGH55HA HGW55HA

HGH65CA HGW65CA HGH65HA HGW65HA

THK

SNR25R SNR25C SHW17CA HSR20CA GSR15T SRS9WM RSR15

SNR25LR SNR25LC SHW27CA HSR20A GSR15TUU SRS12 RSR15ZM

SNR35R SNR35C SHW21CR HSR25A SRS9XM RSR15WV SRS5M

SNR35LR SNR35LC SHW12CR HSR15CA SRS15XM RSR15ZM SRS7M

SNR45R SNR45C HSR25CA SRS12M RSR12VM SNR45LR SNR45LC

SNR55LR SNR55LC HSR55R SRS9KM HSR45A SRS15M HSR65HA SSR20XV SHS15C HR1530UU SRG55LC HRW21CR NR45R SVR45C

SR15W SSR25XV SHS25C HR4085TUU SRG45LR HRW21CA NR45LR

SHS35C HR3575TUU SRG20LV HRW17CA NR65R SNS35R

PMI

MSA15A MSA15E MSA15S MSB15T MSB15TS MSR25E MSR25S

MSA20A MSA20E MSA20S MSB15E MSB15S MSR25LE MSR25LS

MSA20LA MSA20LE MSA20LS MSB20TE MSB20TS MSR30E MSR30S

MSA25A MSA25E MSA25S MSB20E MSB20S MSR30LE MSR30LS

MSA25LA MSA25LE MSA25LS MSB25TE MSB25TS MSR35E MSR35S

MSA30A MSA30E MSA30S MSB25E MSB25S MSR35LE MSR35LS

MSA30LA MSA30LE MSA30LS MSB30TE MSB30TS MSR45E MSR45S

MSA35A MSA35E MSA35S MSB30E MSB30S MSR45LE MSR45LS

MSA35LA MSA35LE MSA35LS MSB35TE MSB35TS MSR55E MSR55S

MSA45A MSA45E MSA45S MSB35E MSB35S MSR55LE MSR55LS

MSA45LA MSA45LE MSA45LS MSB35LE MSB35LS MSR65LE MSR65LS

MSC7M MSD7M SME15EA SME15EB SME15SA SME15SB SMR25E SMR25S

MSC7LM MSD7LM SME15LEA SME15LEB SME15LSA SME15LSB SMR25LE SMR25LS

MSC9M MSD9M SME20EA SME20EB SME20SA SME20SB SMR30E SMR30S

MSC9LM MSD9LM SME20LEA SME20LEB SME20LSA SME20LSB SMR30LE SMR30LS

MSC12M MSD12M SME25EA SME25EB SME25SA SME25SB SMR35E SMR35S

MSC12LM MSD12LM SME25LEA SME25LEB SME25LSA SME25LSB SMR35LE SMR35LS

APPLICATION

Grinding machine

Drilling machine

Machine center

Lathe

XYZ axes of heavy cutting machine tools

Grinding head feeding axies of grinding machines

Milling machine

Z axies of boring machine and machine tools

Z axies of industrial machine

Measuring equipment

Precision XY table

Welding machine

Binding machine

Auto packing machine

Automatic equipment

High speed transfer device

Semiconductor equipment

Wood cutting machine

Laser cutting machine

Laser marking machine

Blow moulding machine

Sing axies robot-robotics

Medical equipment

CNC machine centers

Wire cutting machines

Plano millers

FLOWTECH Machinary & Engineering

HangZhou FlowTech Machinary & Engineering Co., Ltd. as the agent of the brand mechanical CZPT rail. With the accumulated knowledge and professional skills over the years, will provide users with a variety of brands and models to choose, facing the future development.

Company’s main Japan THK, ZheJiang CPC, CSK, PMI, HIWIN, TBI, ASK, and domestic brands of linear guide, rolling guide, miniature CZPT rail and other rail products, suitable for grinding machine, lathe, drilling machine, integrated machine, wire cutting machine, precision measuring instrument industry automation machines, packaging machines, electronic equipment, semiconductor machinery, semiconductor equipment, and other fields.

Adhering to the “integrity-based” business philosophy, we will give full play to the knowledge and expertise we have, to provide the best quality service for the majority of users.

PAYMENT & DELIVERY

FAQ

| 1.Q: Are you a factory or trade company? A: We are factory + trading, brand linear CZPT distributor, can offer high quality product. |

| 2.Q: When can I get the quotation? A: We are usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price. Please call me or tell me in your email so that we will regard you are inquiry priority. |

| 3.Q: Do you provide samples? Is it free or extra? A: Yes. If the sample is simple and of little value, then free samples are provided, but the buyer must bear the international delivery fee. If the sample needs to be ordered, the buyer must bear the sample fee and the international express fee. Please inform us the model you interested, we can offer the price list for your reference. |

| 4.Q: What is your MOQ? A: 1) In stock: MOQ is 1pcs. 2) Not in stock, it depends on the actual situation. |

| 5.Q: What is your terms of payment? A: 1)Payment=5000USD, 30% T/T in advance, balance before shipment. 2)We accept T/T, PayPal, VISA, Western Union payment. |

Why Choose Us? (Our Competitive Advantage)

· Factory outlet, high quality, cheap and cheerful!

· Special logistics line, low shipping cost.

· DDP price for some countries, includes all cost, delivery door to door!

Always with full enthusiasm. sincere cooperation attitude and CZPT business philosophy, we warmly welcome your inquiry!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Magnetically, Corrosion Resistant, High Speed, Low Noise; High Accuracy; Heavy Load Capacity |

|---|---|

| Function: | Super |

| Flange Shape: | Square |

| Shape: | Flange |

| Series: | LM |

| Material: | Stainless Steel |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What materials are typically used in the manufacturing of block bearings?

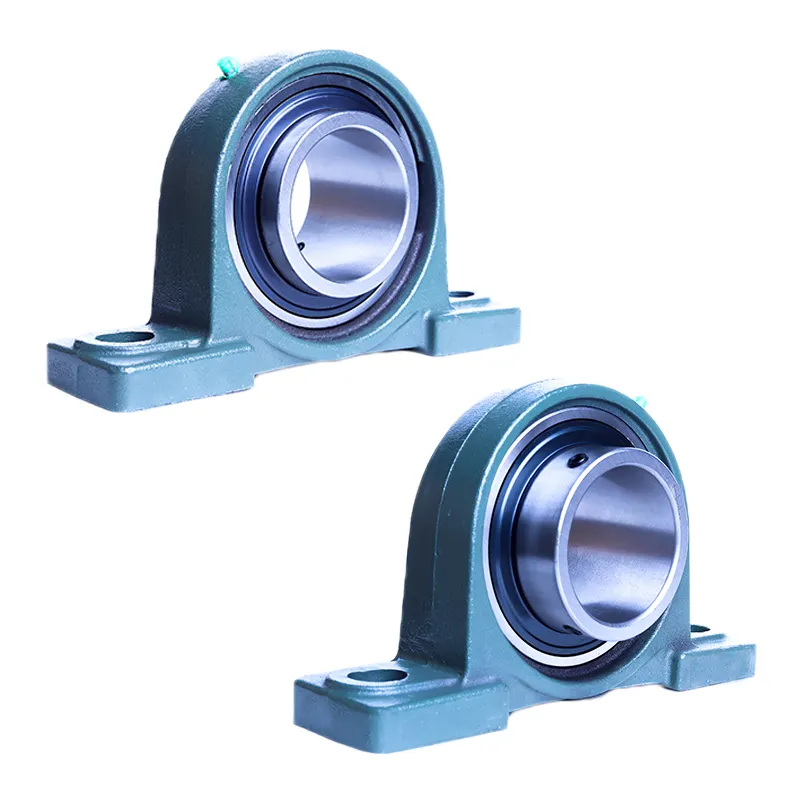

Block bearings, also known as pillow block bearings, are manufactured using a variety of materials to meet different application requirements and operating conditions. Here’s a detailed explanation of the materials that are typically used in the manufacturing of block bearings:

1. Bearing Housing Materials: The housing of a block bearing, also called an outer ring or pillow block, is responsible for providing support and protection to the bearing insert. Common materials used for bearing housings include:

- Cast Iron: Cast iron is a popular material for bearing housings due to its excellent strength, rigidity, and durability. It provides good resistance to shock, vibration, and corrosion. Cast iron housings are commonly used in heavy-duty applications.

- Steel: Steel housings offer high strength and toughness, making them suitable for applications with demanding operating conditions. They provide good resistance to impact, wear, and corrosion.

- Stainless Steel: Stainless steel housings are used in applications where corrosion resistance is critical. They are particularly suitable for environments with high humidity, moisture, or chemical exposure.

- Thermoplastic: Thermoplastic housings, typically made of materials such as polyamide or PBT (polybutylene terephthalate), offer excellent chemical resistance and can be suitable for applications where lightweight, non-metallic housings are required.

2. Bearing Insert Materials: The bearing insert, also known as the inner ring, is the component that directly interacts with the rotating shaft. Common materials used for bearing inserts include:

- Chrome Steel: Chrome steel, also known as bearing steel, is a common material for bearing inserts. It offers good hardness, wear resistance, and load-carrying capacity. Chrome steel inserts are suitable for a wide range of applications.

- Stainless Steel: Stainless steel inserts are used in applications where corrosion resistance is crucial. They provide good resistance to moisture, chemicals, and high-temperature environments.

- Ceramic: Ceramic inserts, typically made of materials like silicon nitride or zirconia, offer exceptional hardness, corrosion resistance, and high-temperature capabilities. Ceramic bearings are used in specialized applications that require extreme performance.

3. Lubrication: While not a material used in the construction of block bearings, lubricants play a critical role in their operation. Lubricants, such as grease or oil, are used to reduce friction, dissipate heat, and protect against wear. The selection of the appropriate lubricant depends on factors like operating speed, temperature, and load conditions.

It’s important to note that the specific materials used in the manufacturing of block bearings can vary depending on the manufacturer, application requirements, and industry standards. When selecting a block bearing, it’s advisable to consult the manufacturer’s specifications and guidelines to ensure the chosen materials are suitable for your specific needs.

What is the temperature tolerance for block bearings?

The temperature tolerance for block bearings can vary depending on factors such as the bearing design, materials used, lubrication, and specific application requirements. Block bearings are designed to operate within a certain temperature range to ensure optimal performance, lubrication effectiveness, and overall bearing life. Here are some key points regarding the temperature tolerance of block bearings:

1. Standard Temperature Range: In general, standard block bearings are designed to operate within a temperature range of -20°C to +120°C (-4°F to +248°F). This temperature range covers a wide range of industrial applications and is suitable for many common operating conditions. It is important to note that this is a general guideline, and specific bearing models or manufacturers may have their own temperature specifications.

2. High-Temperature Bearings: For applications that involve higher temperatures beyond the standard range, special high-temperature block bearings are available. These bearings are designed to withstand elevated temperatures and can operate reliably in conditions up to 200°C (392°F) or higher, depending on the specific design and materials used. High-temperature bearings typically incorporate heat-resistant materials and special lubricants to ensure stability and performance under extreme temperatures.

3. Low-Temperature Bearings: In applications where extremely low temperatures are encountered, such as in refrigeration or cryogenic environments, low-temperature block bearings may be required. These bearings are designed to withstand cold temperatures and maintain their performance even at temperatures as low as -50°C (-58°F) or lower. Special attention is given to the selection of materials and lubricants that can withstand low temperatures without compromising the bearing’s functionality.

4. Temperature Limitations: It’s crucial to consider the temperature limitations specified by the bearing manufacturer. Operating a block bearing outside of its recommended temperature range can lead to premature wear, lubrication breakdown, reduced load capacity, or even catastrophic failure. Factors such as the bearing’s materials, lubrication type, sealing, and cage design can all contribute to the temperature limitations of the bearing.

5. Lubrication Considerations: Proper lubrication is essential for maintaining the performance and temperature tolerance of block bearings. Lubricants have specific temperature ranges within which they can effectively operate. It’s important to select lubricants that are suitable for the anticipated operating temperatures to ensure proper lubrication and prevent issues like excessive friction, overheating, or lubricant degradation.

6. Consult Manufacturer Specifications: To determine the temperature tolerance of a specific block bearing, it is important to consult the manufacturer’s specifications, technical data sheets, or contact the manufacturer directly. They can provide detailed information about the recommended temperature range, limitations, and any special considerations for the specific bearing model.

Overall, the temperature tolerance of block bearings can vary depending on the specific design, materials, and lubrication used. It is crucial to select the appropriate bearing that matches the anticipated operating temperature to ensure reliable performance, minimize wear, and prolong the bearing’s service life.

How is a block bearing different from other types of bearings?

A block bearing, also known as a pillow block bearing, has several distinct characteristics that differentiate it from other types of bearings. Here’s a detailed explanation of how a block bearing differs from other bearing types:

1. Housing Design: One of the key differences of a block bearing is its housing design. A block bearing features a solid block-shaped housing that provides support and stability to the bearing insert. This housing is typically made of materials like cast iron, stainless steel, or thermoplastics, and it often has mounting holes or slots for easy installation onto a support structure.

2. Mounting: Block bearings are designed to be easily mounted and secured onto a support structure, such as a frame or housing. The housing of a block bearing has mounting holes or slots that allow for straightforward attachment using bolts or fasteners. This mounting design provides stability and ensures that the bearing remains in place during operation.

3. Bearing Insert: Another distinct feature of a block bearing is the bearing insert it uses. The bearing insert in a block bearing is typically a ball bearing or a roller bearing. These bearing inserts are designed to facilitate smooth rotational motion of a shaft or rod while providing support and load-carrying capacity.

4. Application: Block bearings are commonly used in applications where there is a need to support and guide a rotating or oscillating shaft. They are widely utilized in various industrial machinery and equipment, such as conveyors, fans, pumps, agricultural machinery, and mining equipment. The block bearing’s robust design and ability to handle radial and axial loads make it suitable for these types of applications.

5. Versatility: Block bearings offer versatility in terms of size, configuration, and design. They are available in different sizes to accommodate various shaft diameters and load requirements. Additionally, block bearings can be used in different mounting positions, such as horizontal, vertical, or inclined, depending on the specific application needs.

6. Maintenance: Block bearings generally require regular maintenance, including lubrication, to ensure optimal performance and longevity. Lubrication helps reduce friction and wear between the bearing components, ensuring smooth operation. Many block bearings feature grease fittings or seals that allow for easy lubrication and help protect the bearing from contaminants.

While block bearings have their unique characteristics, it’s important to note that there are many other types of bearings available, each with its own advantages and applications. Some common types of bearings include deep groove ball bearings, cylindrical roller bearings, tapered roller bearings, and spherical roller bearings. The selection of the appropriate bearing type depends on factors such as load capacity, speed, operating conditions, and specific application requirements.

By understanding the differences between various bearing types, it becomes easier to select the most suitable bearing for a particular application.

editor by CX 2024-05-08

China factory SBR Round Linear Guide CNC Linear Guide Way Rail Kit Set 2PCS Fully Support SBR 12 12mm Ball Bearing Linear Slide Rail Shaft + 4PCS SBR12uu Block Bearing with Hot selling

Product Description

PRODUCT DESCRIPTION

Advantages and Features of Linear Xihu (West Lake) Dis.ways

Δ High positional accuracy

Δ Long life with high motion accuracy

Δ High speed motion is possible with a low driving force

Δ Equal loading capacity in all directions

Δ Easy installation

Δ Easy lubrication

Δ Interchangeability

THK: SHS, SSR, SHW, SRS, SCR, EPF, HSR, SR, HRW, HR, GSR/GSR-R, GSR Series

HIWIN: HG, WE, RG, MGN, QH, QE, PG, CG Series

CPC: MR, ST Series

CSK: LMG, END-M, CS Series

PMI: HG, EG, MGN/MGW Series

TBR: TM, TR Series

TBI, REXROTH, IKO, SBR, etc

HIWIN

HGH15CA HGW15CA HGL15CA EGH15SA EGW15SA CGH15CA CGW15CA MGN5C MGW5C

HGH20CA HGW20CA HGL25CA EGH15CA EGW15CA CGH15HA CGW15HA MGN7C MGW7C

HGH20HA HGW20HA HGL25HA EGH20SA EGW20SA CGH20CA CGW20CA MGN7H MGW7H

HGH25CA HGW25CA HGL30CA EGH20CA EGW20CA CGH20HA CGW20HA MGN9C MGW9C

HGH25HA HGW25HA HGL30HA EGH25SA EGW25SA CGH25CA CGW25CA MGN9H MGW9H

HGH30CA HGW30CA HGL35CA EGH25CA EGW25CA CGH25HA CGW25HA MGN12C MGW12C

HGH30HA HGW30HA HGL35HA EGH30SA EGW30SA CGH30CA CGW30CA MGN12H MGW12H

HGH35CA HGW35CA HGL45CA EGH30CA EGW30CA CGH30HA CGW30HA MGN15C MGW15C

HGH35HA HGW35HA HGL45HA EGH35SA EGW35SA CGH35CA CGW35CA MGN15H MGW15H

HGH45CA HGW45CA HGL55CA EGH35CA EGW35CA CGH35HA CGW35HA HGH45HA HGW45HA HGL55HA CGH45CA CGW45CA HGH55CA HGW55CA CGH45HA CGW45HA HGH55HA HGW55HA

HGH65CA HGW65CA HGH65HA HGW65HA

THK

SNR25R SNR25C SHW17CA HSR20CA GSR15T SRS9WM RSR15

SNR25LR SNR25LC SHW27CA HSR20A GSR15TUU SRS12 RSR15ZM

SNR35R SNR35C SHW21CR HSR25A SRS9XM RSR15WV SRS5M

SNR35LR SNR35LC SHW12CR HSR15CA SRS15XM RSR15ZM SRS7M

SNR45R SNR45C HSR25CA SRS12M RSR12VM SNR45LR SNR45LC

SNR55LR SNR55LC HSR55R SRS9KM HSR45A SRS15M HSR65HA SSR20XV SHS15C HR1530UU SRG55LC HRW21CR NR45R SVR45C

SR15W SSR25XV SHS25C HR4085TUU SRG45LR HRW21CA NR45LR

SHS35C HR3575TUU SRG20LV HRW17CA NR65R SNS35R

PMI

MSA15A MSA15E MSA15S MSB15T MSB15TS MSR25E MSR25S

MSA20A MSA20E MSA20S MSB15E MSB15S MSR25LE MSR25LS

MSA20LA MSA20LE MSA20LS MSB20TE MSB20TS MSR30E MSR30S

MSA25A MSA25E MSA25S MSB20E MSB20S MSR30LE MSR30LS

MSA25LA MSA25LE MSA25LS MSB25TE MSB25TS MSR35E MSR35S

MSA30A MSA30E MSA30S MSB25E MSB25S MSR35LE MSR35LS

MSA30LA MSA30LE MSA30LS MSB30TE MSB30TS MSR45E MSR45S

MSA35A MSA35E MSA35S MSB30E MSB30S MSR45LE MSR45LS

MSA35LA MSA35LE MSA35LS MSB35TE MSB35TS MSR55E MSR55S

MSA45A MSA45E MSA45S MSB35E MSB35S MSR55LE MSR55LS

MSA45LA MSA45LE MSA45LS MSB35LE MSB35LS MSR65LE MSR65LS

MSC7M MSD7M SME15EA SME15EB SME15SA SME15SB SMR25E SMR25S

MSC7LM MSD7LM SME15LEA SME15LEB SME15LSA SME15LSB SMR25LE SMR25LS

MSC9M MSD9M SME20EA SME20EB SME20SA SME20SB SMR30E SMR30S

MSC9LM MSD9LM SME20LEA SME20LEB SME20LSA SME20LSB SMR30LE SMR30LS

MSC12M MSD12M SME25EA SME25EB SME25SA SME25SB SMR35E SMR35S

MSC12LM MSD12LM SME25LEA SME25LEB SME25LSA SME25LSB SMR35LE SMR35LS

APPLICATION

Grinding machine

Drilling machine

Machine center

Lathe

XYZ axes of heavy cutting machine tools

Grinding head feeding axies of grinding machines

Milling machine

Z axies of boring machine and machine tools

Z axies of industrial machine

Measuring equipment

Precision XY table

Welding machine

Binding machine

Auto packing machine

Automatic equipment

High speed transfer device

Semiconductor equipment

Wood cutting machine

Laser cutting machine

Laser marking machine

Blow moulding machine

Sing axies robot-robotics

Medical equipment

CNC machine centers

Wire cutting machines

Plano millers

FLOWTECH Machinary & Engineering

HangZhou FlowTech Machinary & Engineering Co., Ltd. as the agent of the brand mechanical CZPT rail. With the accumulated knowledge and professional skills over the years, will provide users with a variety of brands and models to choose, facing the future development.

Company’s main Japan THK, ZheJiang CPC, CSK, PMI, HIWIN, TBI, ASK, and domestic brands of linear guide, rolling guide, miniature CZPT rail and other rail products, suitable for grinding machine, lathe, drilling machine, integrated machine, wire cutting machine, precision measuring instrument industry automation machines, packaging machines, electronic equipment, semiconductor machinery, semiconductor equipment, and other fields.

Adhering to the “integrity-based” business philosophy, we will give full play to the knowledge and expertise we have, to provide the best quality service for the majority of users.

PAYMENT & DELIVERY

FAQ

| 1.Q: Are you a factory or trade company? A: We are factory + trading, brand linear CZPT distributor, can offer high quality product. |

| 2.Q: When can I get the quotation? A: We are usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price. Please call me or tell me in your email so that we will regard you are inquiry priority. |

| 3.Q: Do you provide samples? Is it free or extra? A: Yes. If the sample is simple and of little value, then free samples are provided, but the buyer must bear the international delivery fee. If the sample needs to be ordered, the buyer must bear the sample fee and the international express fee. Please inform us the model you interested, we can offer the price list for your reference. |

| 4.Q: What is your MOQ? A: 1) In stock: MOQ is 1pcs. 2) Not in stock, it depends on the actual situation. |

| 5.Q: What is your terms of payment? A: 1)Payment=5000USD, 30% T/T in advance, balance before shipment. 2)We accept T/T, PayPal, VISA, Western Union payment. |

Why Choose Us? (Our Competitive Advantage)

· Factory outlet, high quality, cheap and cheerful!

· Special logistics line, low shipping cost.

· DDP price for some countries, includes all cost, delivery door to door!

Always with full enthusiasm. sincere cooperation attitude and CZPT business philosophy, we warmly welcome your inquiry!

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Magnetically, Corrosion Resistant, High Speed, Low Noise; High Accuracy; Heavy Load Capacity |

|---|---|

| Function: | Super |

| Flange Shape: | Square |

| Shape: | Flange |

| Series: | LM |

| Material: | Stainless Steel |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do I choose the right block bearing for my machinery?

Choosing the right block bearing for your machinery is crucial to ensure optimal performance, reliability, and longevity. Here’s a detailed explanation of the factors to consider when selecting a block bearing:

- Load Requirements: Determine the load requirements of your machinery, including the magnitude and direction of the loads that will be applied to the bearing. Consider factors such as static loads, dynamic loads, and shock loads. This information will help you choose a block bearing with the appropriate load-carrying capacity and load rating.

- Speed and Operating Conditions: Consider the speed at which your machinery will operate and the corresponding operating conditions. High-speed applications may require block bearings with specific design features, such as lower friction, improved heat dissipation, and higher precision. Additionally, assess the operating environment for factors like temperature, humidity, dust, and chemical exposure, as these can impact the choice of bearing materials and seals.

- Bearing Type and Configuration: Choose the appropriate bearing type and configuration based on your machinery’s requirements. Common types of block bearings include ball bearings, roller bearings, and spherical bearings. Consider factors such as the type of motion, misalignment compensation, and ease of installation when selecting the bearing type.

- Bearing Size and Shaft Diameter: Determine the required bearing size and shaft diameter for your machinery. The bearing should be properly sized to handle the loads and fit securely on the shaft. Refer to manufacturer guidelines or consult engineering resources to determine the appropriate bearing size and shaft diameter for your specific application.

- Sealing and Lubrication: Consider the sealing and lubrication requirements of your machinery. Sealing arrangements help protect the bearing from contaminants and retain lubrication. Choose the appropriate sealing options based on the operating environment and the desired level of protection. Additionally, select the right lubricant and lubrication method based on factors such as operating speed, temperature, and load conditions.

- Industry Standards and Regulations: Ensure that the selected block bearing complies with relevant industry standards and regulations. Compliance with standards such as ISO, ANSI, or ABMA ensures that the bearing meets quality and performance requirements.

- Consult Manufacturer or Supplier: If you are unsure about the appropriate block bearing for your machinery, consult the manufacturer or a reputable supplier. They can provide expert guidance, technical support, and recommend suitable products based on their experience and knowledge.

By considering these factors and seeking expert advice when needed, you can choose the right block bearing that matches the requirements of your machinery, ensuring reliable and efficient operation.

What is the lifespan of a block bearing?

The lifespan of a block bearing can vary depending on several factors, including the operating conditions, the type of bearing, the quality of the bearing and its components, and the level of maintenance and lubrication. It is challenging to provide an exact lifespan for a block bearing as it can be influenced by these variables. However, with proper installation, maintenance, and operating conditions, block bearings can have a long service life.

The manufacturer of the block bearing typically provides an estimated service life or a rating for the bearing under specific conditions. This rating is often referred to as the L10 life or the basic rating life. The L10 life represents the number of hours that 90% of a group of identical bearings are expected to operate before the onset of fatigue failure. It is important to note that the L10 life is a statistical calculation based on standardized testing and assumptions about operating conditions. Actual bearing life can vary significantly depending on the application.

Several factors can influence the lifespan of a block bearing:

- Operating Conditions: The operating conditions, including the load magnitude and direction, speed, and temperature, can significantly impact the lifespan of a block bearing. Higher loads, excessive speeds, and extreme temperatures can accelerate wear and fatigue, reducing the bearing’s lifespan.

- Maintenance and Lubrication: Regular maintenance practices, including proper lubrication, can help extend the lifespan of a block bearing. Inadequate or improper lubrication can lead to increased friction, wear, and premature failure. Regular inspection, cleaning, and re-lubrication according to the manufacturer’s recommendations are essential for optimal bearing performance and longevity.

- Quality and Design: The quality of the block bearing and its components, as well as the design and manufacturing standards, can impact its lifespan. High-quality bearings manufactured by reputable companies tend to have more consistent performance and longer lifespans compared to lower-quality alternatives.

- Application-Specific Factors: Certain applications may expose block bearings to harsh or demanding conditions, such as heavy loads, high vibrations, or corrosive environments. These factors can affect the bearing’s lifespan and may require special considerations in terms of bearing selection, materials, and maintenance.

It is important to monitor the condition of block bearings regularly and be vigilant for any signs of wear, damage, or decreased performance. By addressing issues promptly, performing routine maintenance, and following proper operating practices, it is possible to maximize the lifespan of block bearings and ensure reliable operation of the machinery.

Ultimately, the lifespan of a block bearing can vary, and it is recommended to consult the manufacturer’s guidelines and work with qualified engineers or technicians to determine the expected lifespan in specific operating conditions.

What are the standard dimensions for block bearings?

The dimensions of block bearings, also known as pillow block bearings, can vary depending on the specific design and manufacturer. However, there are standard dimensions that are commonly used in the industry. Here’s a detailed explanation of the standard dimensions for block bearings:

Block bearings consist of a bearing insert (also called an inner ring) and a housing (also called an outer ring or pillow block). The housing is typically a solid or split housing with mounting holes for attachment to a support structure. The bearing insert is designed to fit inside the housing and supports the rotating shaft. The dimensions of block bearings are typically specified using the following parameters:

- Shaft Diameter (d): This refers to the diameter of the shaft that will be inserted into the bearing. The standard shaft diameters for block bearings range from a few millimeters up to several inches, depending on the application requirements. Common shaft diameter sizes include 1/2″, 5/8″, 3/4″, 1″, 1-1/4″, 1-1/2″, and 2″.

- Housing Length (L): The housing length refers to the distance between the mounting surfaces of the housing. It determines the overall length of the block bearing assembly. The housing length can vary depending on the bearing size and design, but common lengths range from around 2 inches to several inches or more.

- Housing Width (B): The housing width refers to the width of the housing, perpendicular to the shaft. It determines the overall width of the block bearing assembly. The housing width can vary depending on the bearing size and design, but common widths range from around 1 inch to several inches or more.

- Mounting Hole Spacing (Bolt Hole Centers): Block bearings typically have multiple mounting holes for attachment to the support structure. The mounting hole spacing refers to the distance between the centers of these mounting holes. The standard mounting hole spacing is often specified using a bolt hole center-to-center distance, such as 2-bolt, 3-bolt, or 4-bolt configurations. The specific dimensions can vary depending on the bearing size and design.

- Bearing Insert Width (Bearing Width): The bearing insert width refers to the width of the bearing insert itself. It determines the amount of support and contact area for the rotating shaft. The bearing insert width can vary depending on the bearing size and design, but common widths range from around 0.5 inch to several inches or more.

It’s important to note that these are general standard dimensions, and variations may exist depending on the specific manufacturer and bearing type. Additionally, some block bearings may have additional features or variations in dimensions to cater to specific applications or industry requirements.

When selecting a block bearing, it’s crucial to consider the specific dimensions required for your application, including the shaft diameter, housing length and width, and mounting hole spacing. Consulting the manufacturer’s specifications and guidelines is recommended to ensure the correct dimensions are chosen for your specific needs.

editor by CX 2024-02-08