Product Description

Product Description

The bearing is composed of several layers of rubber sheet and thin steel plate superimposed by pressure vulcanization, which has enough vertical stiffness to meet the vertical load, and has good elasticity to adapt to the rotation of the beam end. It has large shear deformation to meet the water of the superstructure horizontal displacement, and has a good seismic effect, can reduce the dynamic load on the upper structure and pier impact.

Mechanical Properties of Rubber

| Technical index | Neoprene Rubber | Natural Rubber | |

| Hardness (IRHD) | 60±5 | 60±5 | |

| Strength Tensile (Mpa) | ≥17 | ≥18 | |

| Elongation at break (%) | ≥400 | ≥450 | |

| Brittleness temperature (ºC) | ≤40 | ≤-50 | |

| Constant compression permanent deformation | ≤15 | ≤30 | |

| Resistance to CZPT aging test (test conditions,20% elongation,40ºC×96h) |

100ppmm | 25ppmm | |

| No cracking | No cracking | ||

| Hot air aging test (The biggest change comparing with before aging numerical) |

Test conditions (ºC×h) | 100×70 | 70×168 |

| Strength Tensile (%) | -15 | -15 | |

| Elongation at break(%) | -40 | -20 | |

| Variation in hardness(IRHD) | 0,+10 | -5,+10 | |

| Strength of rubber and steel Peel adhesive (KN/m) | >10 | >10 | |

| Strength of 4 fluorine plate and rubber (KN/m) | >7 | >7 | |

Features of rubber bridge bearing:

(1) Quality materials including natural rubber, neoprene complying with AASHTO standards.

(2) Allow for expansions and contractions of precast steel structure of bridges.

(3) Capable to control load distribution, meanwhile accommodate thermal and end-beam rotational movements.

(4) Vibration, sounds and shocks isolation.

(5) Avoid excessive load eccentricity and edge compression.

(6) Simple but robust structure.

(7) Lower price than laminated elastomeric bearing.

(8) High cost effectiveness.

(9) Minimal maintenance is needed

Table 1. Rectangular Laminated Elastomeric Bearing Sizes (Width* Length/ mm)

| 100*150 | 100*200 | 150*150 | 150*200 | 150*250 | 150*300 | 200*200 |

| 200*250 | 200*300 | 200*350 | 200*400 | 250*250 | 250*300 | 250*350 |

| 250*400 | 250*450 | 250*500 | 300*300 | 300*350 | 300*400 | 300*450 |

| 300*500 | 300*550 | 300*600 | 350*350 | 350*400 | 350*450 | 350*500 |

| 350*550 | 350*600 | 400*400 | 400*450 | 400*500 | 400*550 | 400*600 |

| 400*650 | 450*450 | 450*500 | 450*550 | 450*600 | 450*650 | 500*500 |

| 500*550 | 500*600 | 500*650 | 500*700 | 550*550 | 550*600 | 550*650 |

| 600*600 | 600*650 | 600*700 | 600*750 | 650*650 | 650*700 | 650*750 |

| 700*700 | With or without the PTFE plate | |||||

Table 2. Round Laminated Elastomeric Bearing Sizes (OD/ mm)

| 150 | 200 | 250 | 300 | 350 | 400 | 450 |

| 500 | 550 | 600 | 650 | 700 | 750 | 800 |

| With or without the PTFE plate | ||||||

Contact:

Ms. Jane

Export Manager

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Technical Guidance |

|---|---|

| Warranty: | 1 Year |

| Certification: | GB, En |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

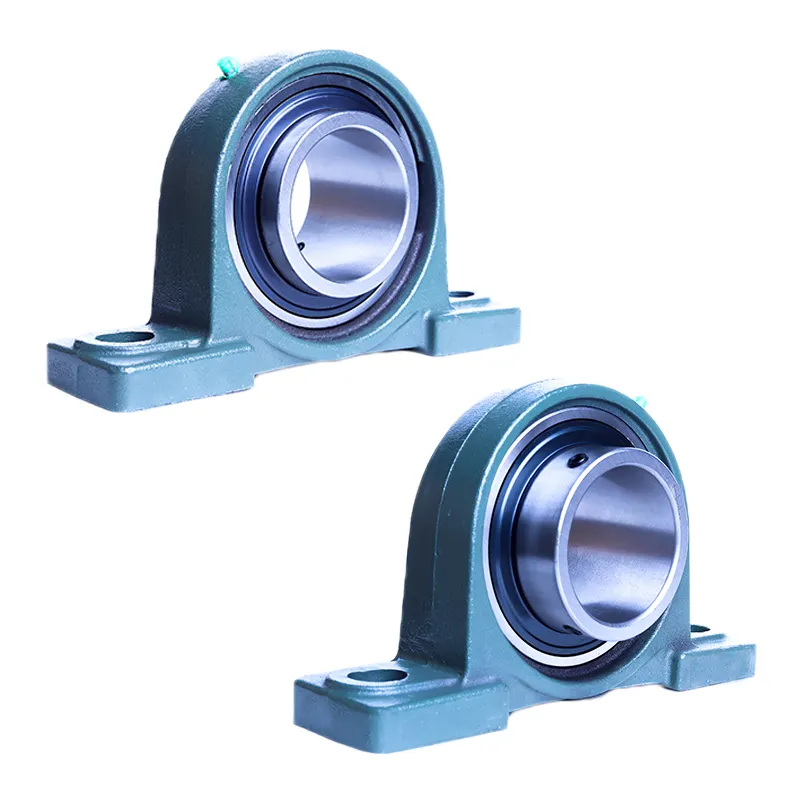

What materials are typically used in the manufacturing of block bearings?

Block bearings, also known as pillow block bearings, are manufactured using a variety of materials to meet different application requirements and operating conditions. Here’s a detailed explanation of the materials that are typically used in the manufacturing of block bearings:

1. Bearing Housing Materials: The housing of a block bearing, also called an outer ring or pillow block, is responsible for providing support and protection to the bearing insert. Common materials used for bearing housings include:

- Cast Iron: Cast iron is a popular material for bearing housings due to its excellent strength, rigidity, and durability. It provides good resistance to shock, vibration, and corrosion. Cast iron housings are commonly used in heavy-duty applications.

- Steel: Steel housings offer high strength and toughness, making them suitable for applications with demanding operating conditions. They provide good resistance to impact, wear, and corrosion.

- Stainless Steel: Stainless steel housings are used in applications where corrosion resistance is critical. They are particularly suitable for environments with high humidity, moisture, or chemical exposure.

- Thermoplastic: Thermoplastic housings, typically made of materials such as polyamide or PBT (polybutylene terephthalate), offer excellent chemical resistance and can be suitable for applications where lightweight, non-metallic housings are required.

2. Bearing Insert Materials: The bearing insert, also known as the inner ring, is the component that directly interacts with the rotating shaft. Common materials used for bearing inserts include:

- Chrome Steel: Chrome steel, also known as bearing steel, is a common material for bearing inserts. It offers good hardness, wear resistance, and load-carrying capacity. Chrome steel inserts are suitable for a wide range of applications.

- Stainless Steel: Stainless steel inserts are used in applications where corrosion resistance is crucial. They provide good resistance to moisture, chemicals, and high-temperature environments.

- Ceramic: Ceramic inserts, typically made of materials like silicon nitride or zirconia, offer exceptional hardness, corrosion resistance, and high-temperature capabilities. Ceramic bearings are used in specialized applications that require extreme performance.

3. Lubrication: While not a material used in the construction of block bearings, lubricants play a critical role in their operation. Lubricants, such as grease or oil, are used to reduce friction, dissipate heat, and protect against wear. The selection of the appropriate lubricant depends on factors like operating speed, temperature, and load conditions.

It’s important to note that the specific materials used in the manufacturing of block bearings can vary depending on the manufacturer, application requirements, and industry standards. When selecting a block bearing, it’s advisable to consult the manufacturer’s specifications and guidelines to ensure the chosen materials are suitable for your specific needs.

Can block bearings handle both radial and axial loads?

Yes, block bearings are designed to handle both radial and axial loads. Block bearings, also known as pillow block bearings or plummer block bearings, are a type of bearing housing that contains a rolling element bearing. These bearings are commonly used in various industrial applications to support rotating shafts and provide support for both radial and axial loads.

The design of block bearings allows them to accommodate radial loads, which are forces acting perpendicular to the shaft’s axis. Radial loads can be caused by the weight of the shaft, the load being transmitted through the shaft, or other external forces acting on the bearing.

In addition to radial loads, block bearings are also capable of handling axial loads, which are forces acting parallel to the shaft’s axis. Axial loads can be caused by thrust or pushing/pulling forces exerted on the bearing. The ability of block bearings to handle axial loads depends on their specific design and configuration.

Block bearings typically consist of a housing (block) and an insert bearing. The housing provides support and protection for the bearing, while the insert bearing is the rolling element bearing that carries the load. The insert bearing can be designed to handle both radial and axial loads, depending on its type and construction.

Some block bearings use deep groove ball bearings as the insert bearing, which are capable of handling both radial and axial loads. Other types of insert bearings, such as spherical roller bearings or tapered roller bearings, are specifically designed to handle higher axial loads in addition to radial loads.

It’s important to consider the specific application requirements and load conditions when selecting block bearings. The manufacturer’s specifications and guidelines should be consulted to ensure that the chosen block bearings are suitable for the expected radial and axial load capacities.

Overall, block bearings are designed to provide support for both radial and axial loads, making them versatile and widely used in various machinery and equipment applications.

What are the standard dimensions for block bearings?

The dimensions of block bearings, also known as pillow block bearings, can vary depending on the specific design and manufacturer. However, there are standard dimensions that are commonly used in the industry. Here’s a detailed explanation of the standard dimensions for block bearings:

Block bearings consist of a bearing insert (also called an inner ring) and a housing (also called an outer ring or pillow block). The housing is typically a solid or split housing with mounting holes for attachment to a support structure. The bearing insert is designed to fit inside the housing and supports the rotating shaft. The dimensions of block bearings are typically specified using the following parameters:

- Shaft Diameter (d): This refers to the diameter of the shaft that will be inserted into the bearing. The standard shaft diameters for block bearings range from a few millimeters up to several inches, depending on the application requirements. Common shaft diameter sizes include 1/2″, 5/8″, 3/4″, 1″, 1-1/4″, 1-1/2″, and 2″.

- Housing Length (L): The housing length refers to the distance between the mounting surfaces of the housing. It determines the overall length of the block bearing assembly. The housing length can vary depending on the bearing size and design, but common lengths range from around 2 inches to several inches or more.

- Housing Width (B): The housing width refers to the width of the housing, perpendicular to the shaft. It determines the overall width of the block bearing assembly. The housing width can vary depending on the bearing size and design, but common widths range from around 1 inch to several inches or more.

- Mounting Hole Spacing (Bolt Hole Centers): Block bearings typically have multiple mounting holes for attachment to the support structure. The mounting hole spacing refers to the distance between the centers of these mounting holes. The standard mounting hole spacing is often specified using a bolt hole center-to-center distance, such as 2-bolt, 3-bolt, or 4-bolt configurations. The specific dimensions can vary depending on the bearing size and design.

- Bearing Insert Width (Bearing Width): The bearing insert width refers to the width of the bearing insert itself. It determines the amount of support and contact area for the rotating shaft. The bearing insert width can vary depending on the bearing size and design, but common widths range from around 0.5 inch to several inches or more.

It’s important to note that these are general standard dimensions, and variations may exist depending on the specific manufacturer and bearing type. Additionally, some block bearings may have additional features or variations in dimensions to cater to specific applications or industry requirements.

When selecting a block bearing, it’s crucial to consider the specific dimensions required for your application, including the shaft diameter, housing length and width, and mounting hole spacing. Consulting the manufacturer’s specifications and guidelines is recommended to ensure the correct dimensions are chosen for your specific needs.

editor by CX 2024-04-30